Test set of electronic component connection socket

A technology for connecting sockets and electronic components, applied in the field of test fixtures to confirm the welding status of connection points, can solve the problem of twice the time spent, and achieve the effect of reducing test procedures and shortening detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

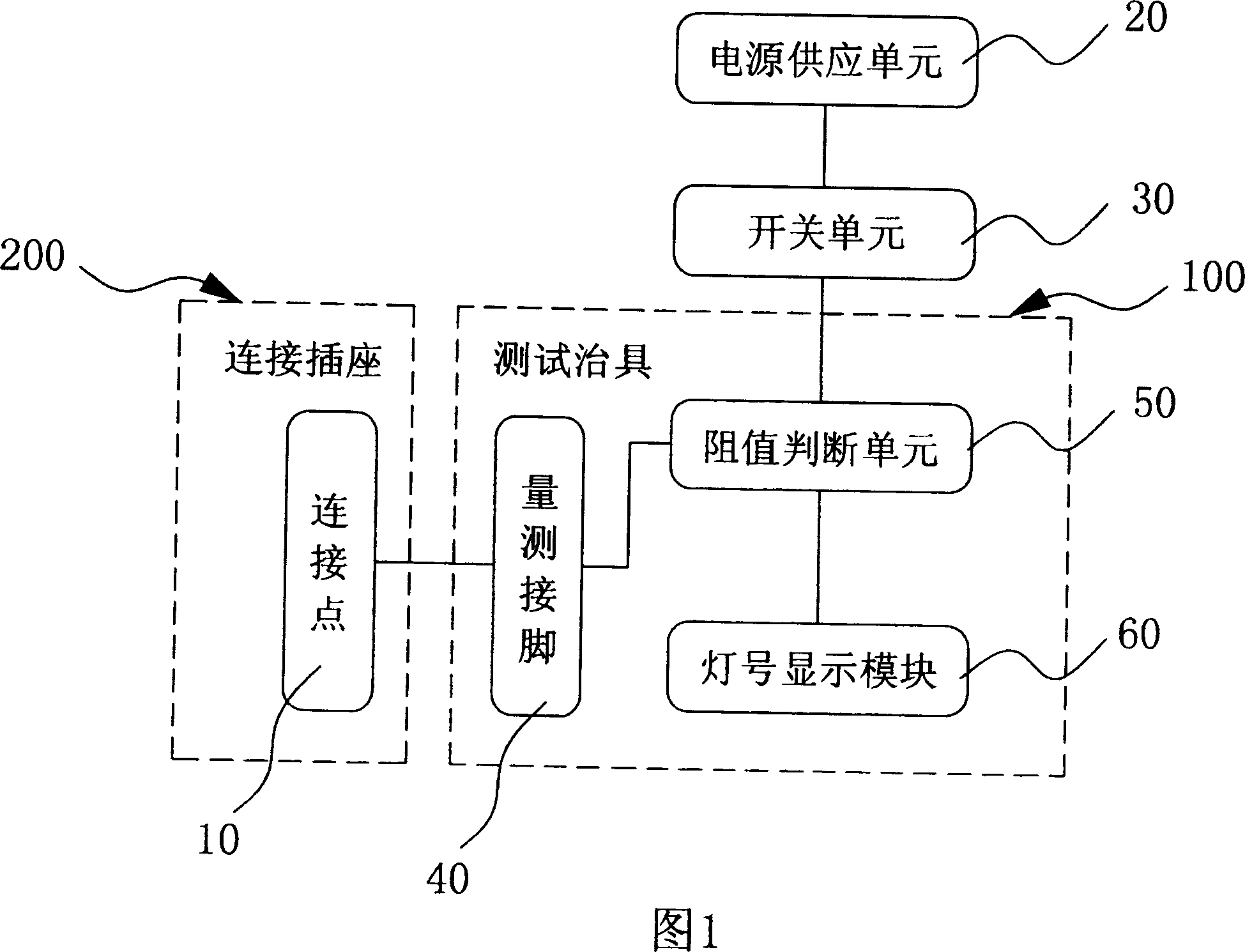

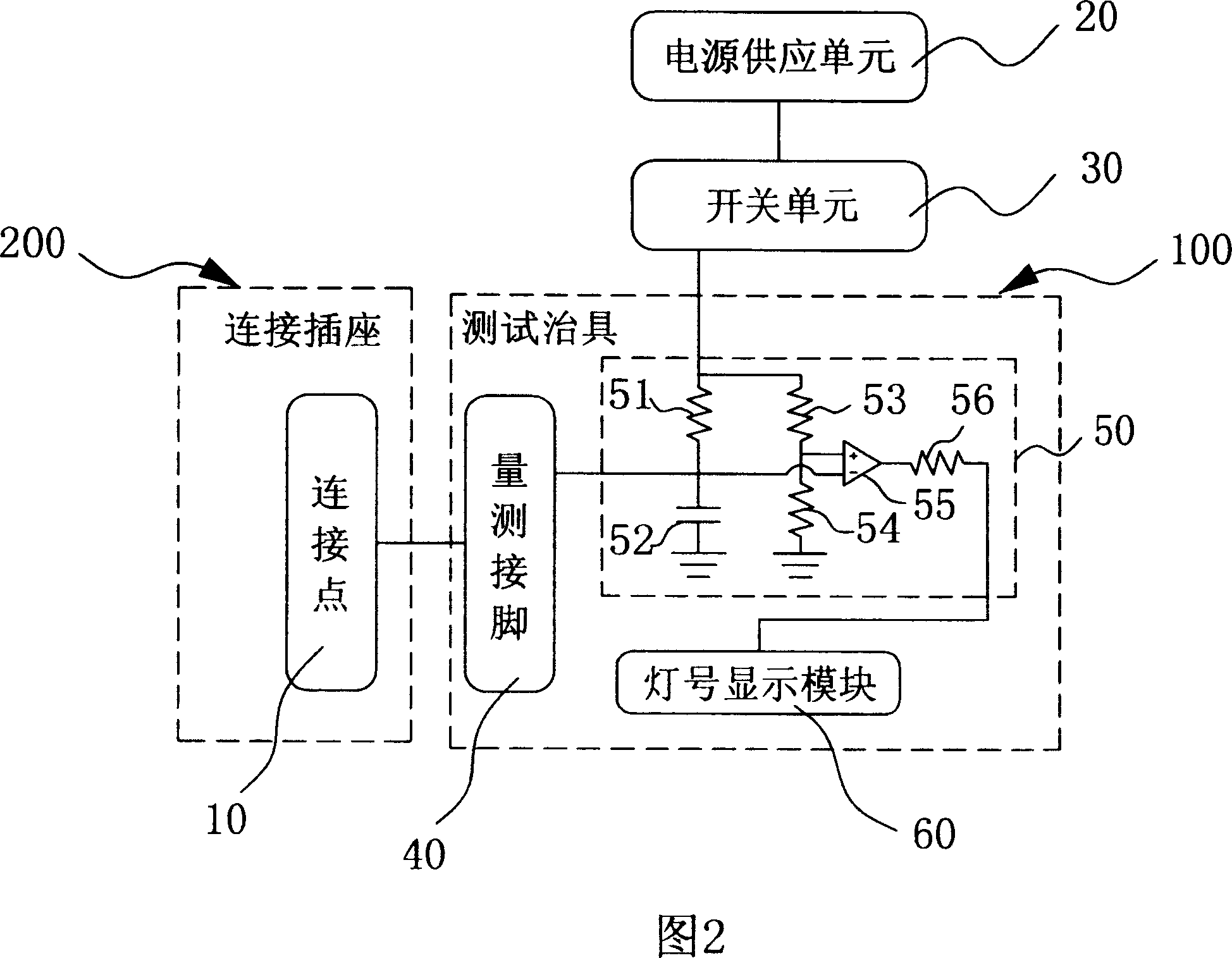

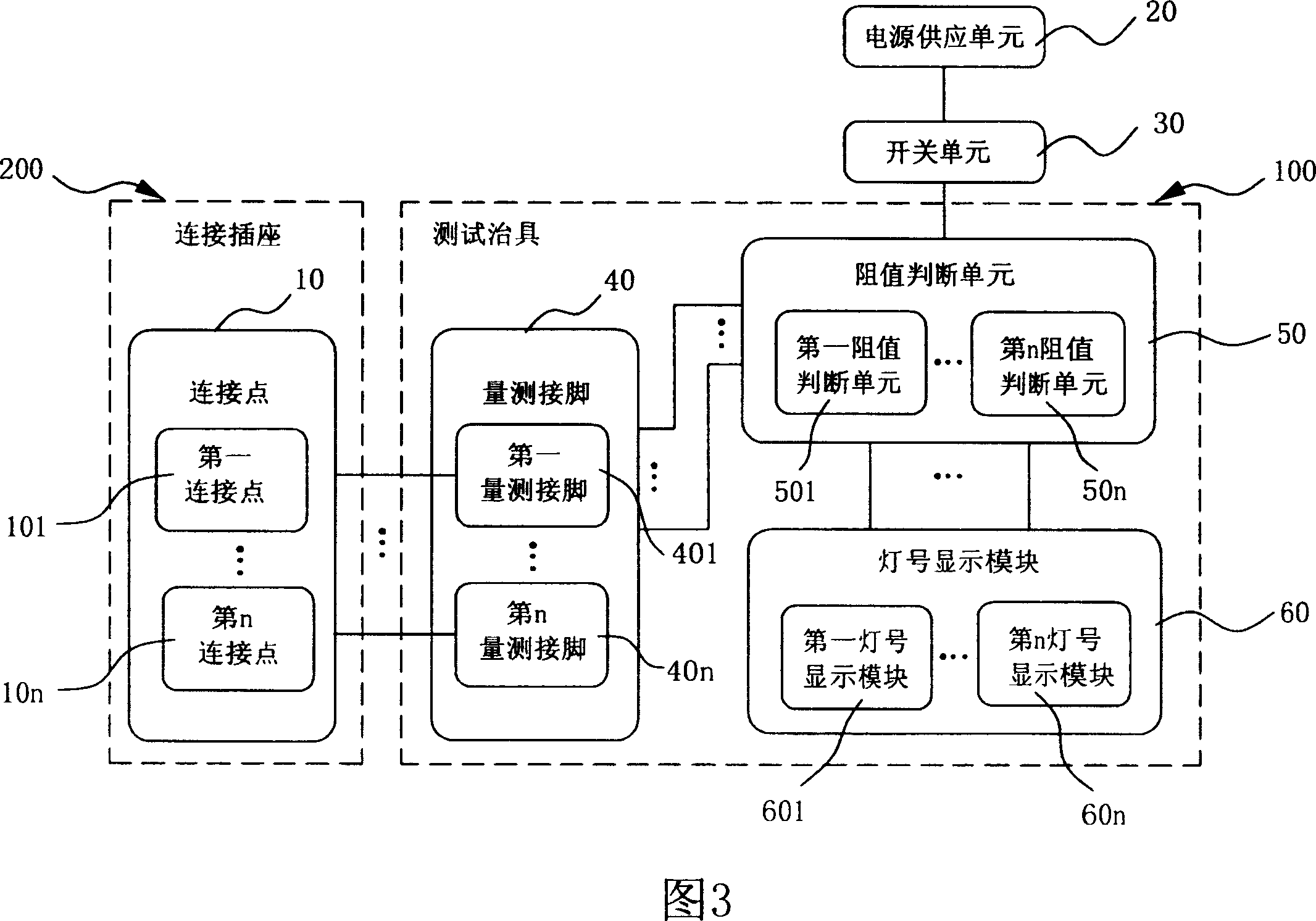

[0015] Please refer to FIG. 1 , the test mechanism includes a power supply unit 20 , a switch unit 30 , a connection socket 200 and a test fixture 100 . In this embodiment, the connection socket 200 can be a connection socket of a central processing unit. Switching through the switch unit 30 enables the power supply unit 20 to provide a test voltage to the test fixture 100, and uses its internal judgment circuit to confirm whether the grounding resistance of the connection socket 200 is normal, whether there is empty welding or cold welding at the connection point 10, etc. defective standards.

[0016] The test fixture 100 mainly includes: (A) measuring pin 40; (B) resistance judgment unit 50; and (C) light signal display module 60, respectively detailed as follows:

[0017] (A) The measurement pin 40 is used to electrically couple with the connection point 10. When the measurement pin 40 is electrically coupled with the connection point 10 through the connection socket 200, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com