Motor-driven vane pump

A vane pump and vane technology, which is applied in pumps, mechanical equipment, machines/engines, etc., can solve the problems of high noise and leakage of power units, and achieve the effect of reliable sealing, low noise and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

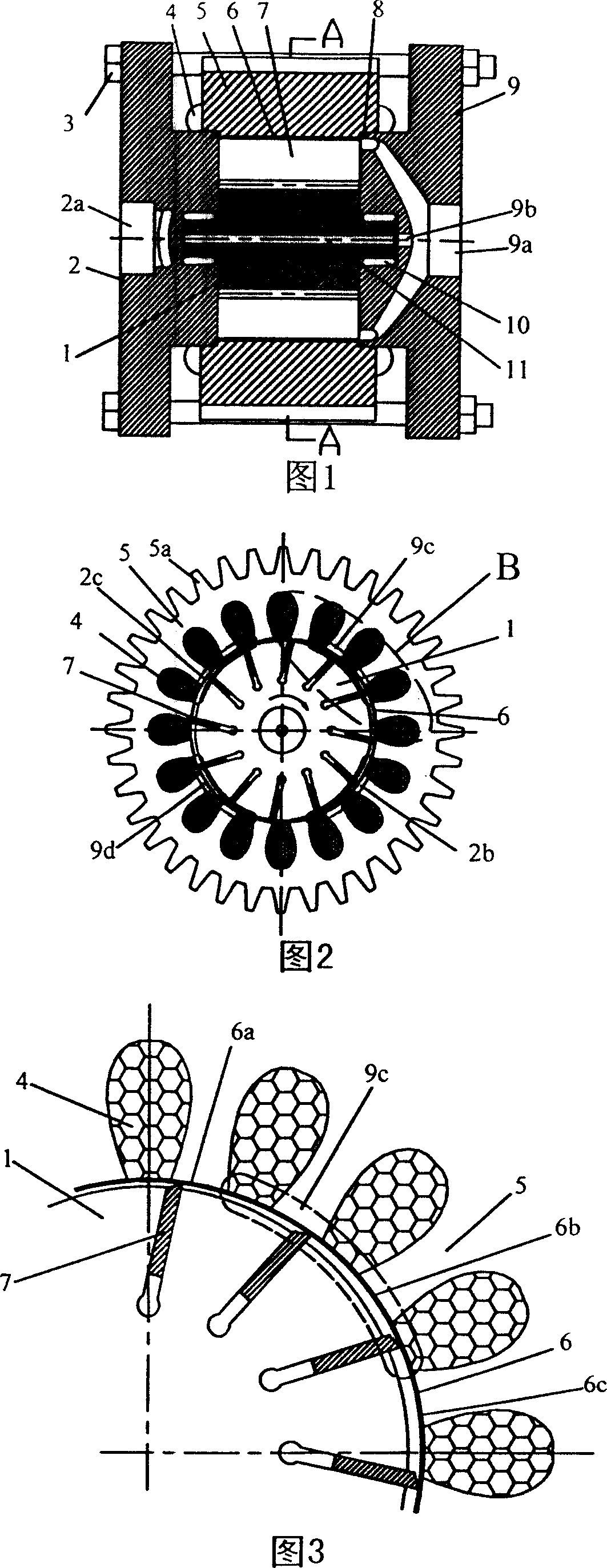

[0011] As shown in Figures 1 to 3, the present invention includes: a plurality of vanes 7 are evenly distributed in the motor rotor 1, the motor rotor 1 is supported in the front pump cover 9 and the rear pump cover 2 by the bearings 10 at both ends of the motor rotor 1, and the motor stator 5 The motor winding 4 is installed in the middle, and the motor stator 5 is provided with an anti-wear insulating coating 6 inside. A sealing ring 8 is installed between the motor stator 5 and the front pump cover 9 and the rear pump cover 2. The front pump cover 9 and the rear pump cover 2 Fastened together with the motor stator 5 by bolts 3.

[0012] The shape of the inner surface of the anti-wear insulating coating 6 is a waist circle composed of two sections of small arcs 6a, two sections of large arcs 6c and four sections of transition curves 6b. The outer circle of the motor stator 5 is evenly distributed with a plurality of cooling bands 5a.

[0013] The motor rotor 1 has a central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com