Compound material forming method and apparatus

A molding method and composite material technology, applied in applications, household components, household appliances, etc., can solve problems such as non-compliance, difficulty in controlling the center positioning of the threading shaft, and reduced utilization of cork blanks, so as to achieve reasonable device structure and work efficiency High, save raw material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

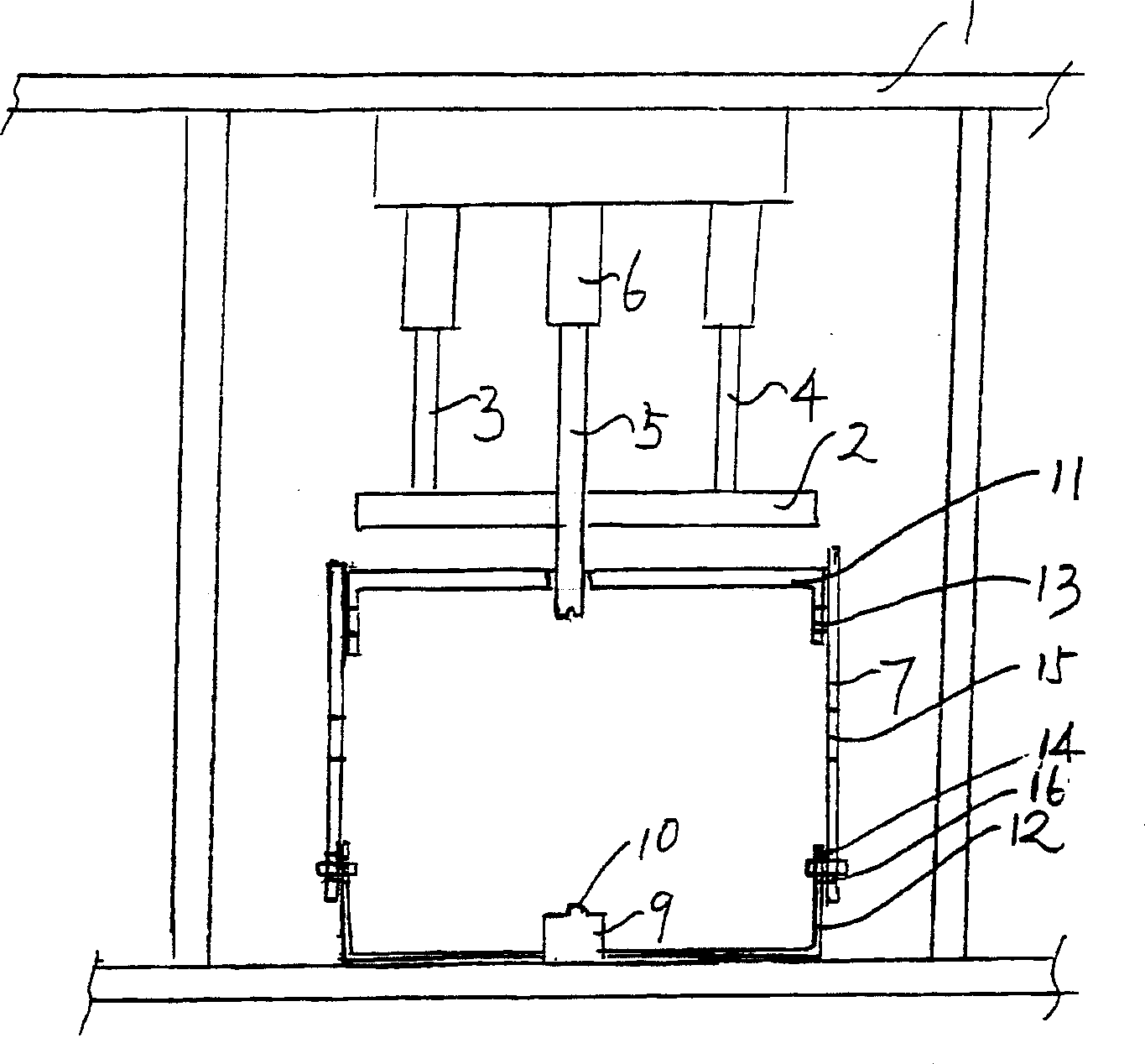

[0017] A special molding device for a composite material molding method, including a frame 1, the upper part of the frame 1 is equipped with a telescopic device 3, 4, and the lower end of the telescopic device is connected with a briquetting block 2, and the briquetting block 2 is provided with a wear-resistant central hole , the bottom of the frame is provided with a central positioning device, the central telescopic positioning shaft 5 is connected with the central telescopic cylinder 6 mounted on the frame, the lower part of the central telescopic positioning shaft 5 is passed through the central hole of the briquetting block, and a mold is arranged below the briquetting block. The mold has a mold body 7. The upper and lower parts of the mold body 7 are respectively provided with a built-in upper cover plate 11 and a built-in lower cover plate 12. The center of the built-in upper cover plate 11 is provided with a center positioning hole that cooperates with the central telesc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com