Hot pipe

A heat pipe and pipe body technology, applied in the field of nanofluid heat pipes, can solve the problems of limited solubility and inability to effectively solve the problems of nanoparticle aggregation and deposition, and achieve the effect of preventing aggregation and deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

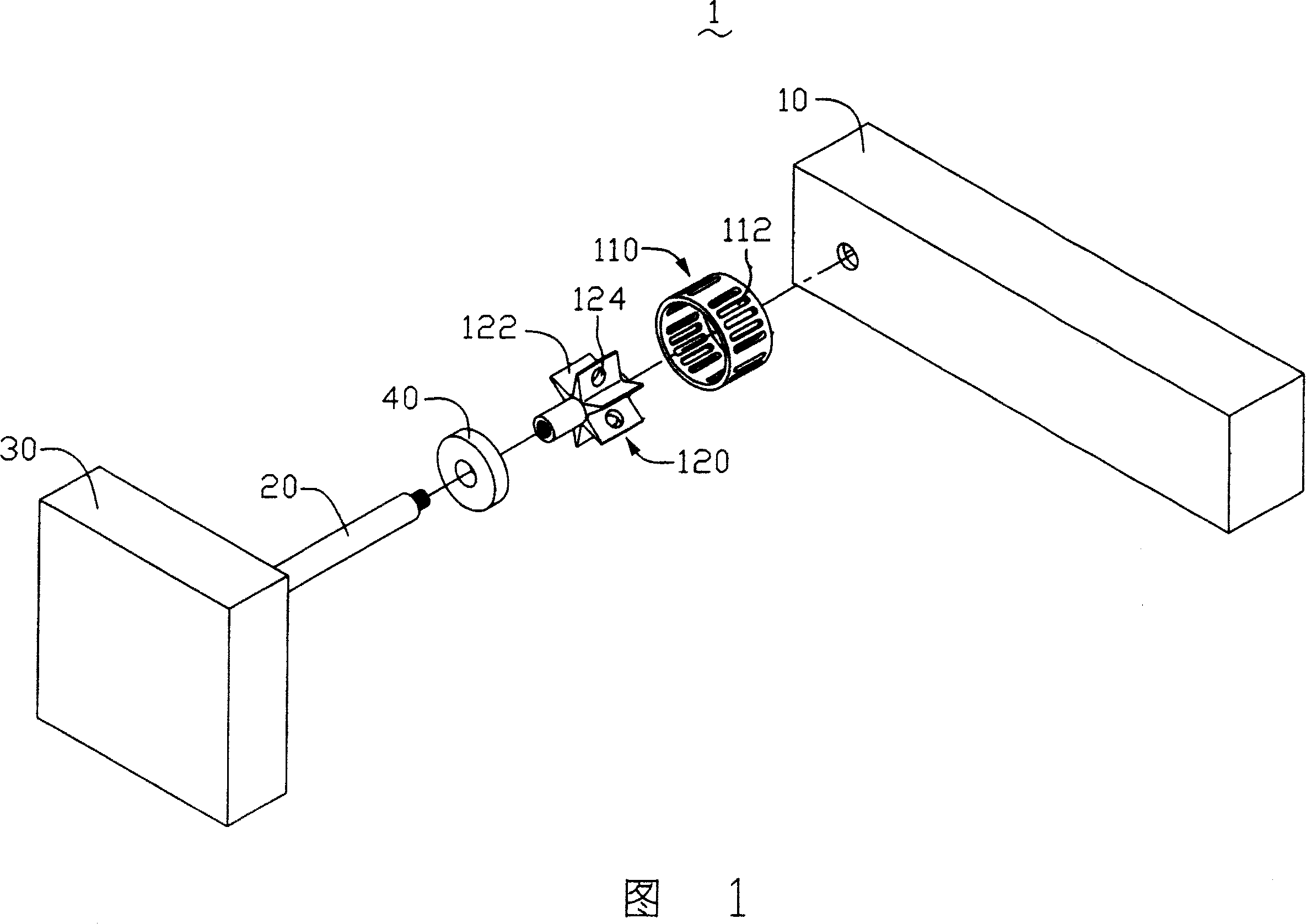

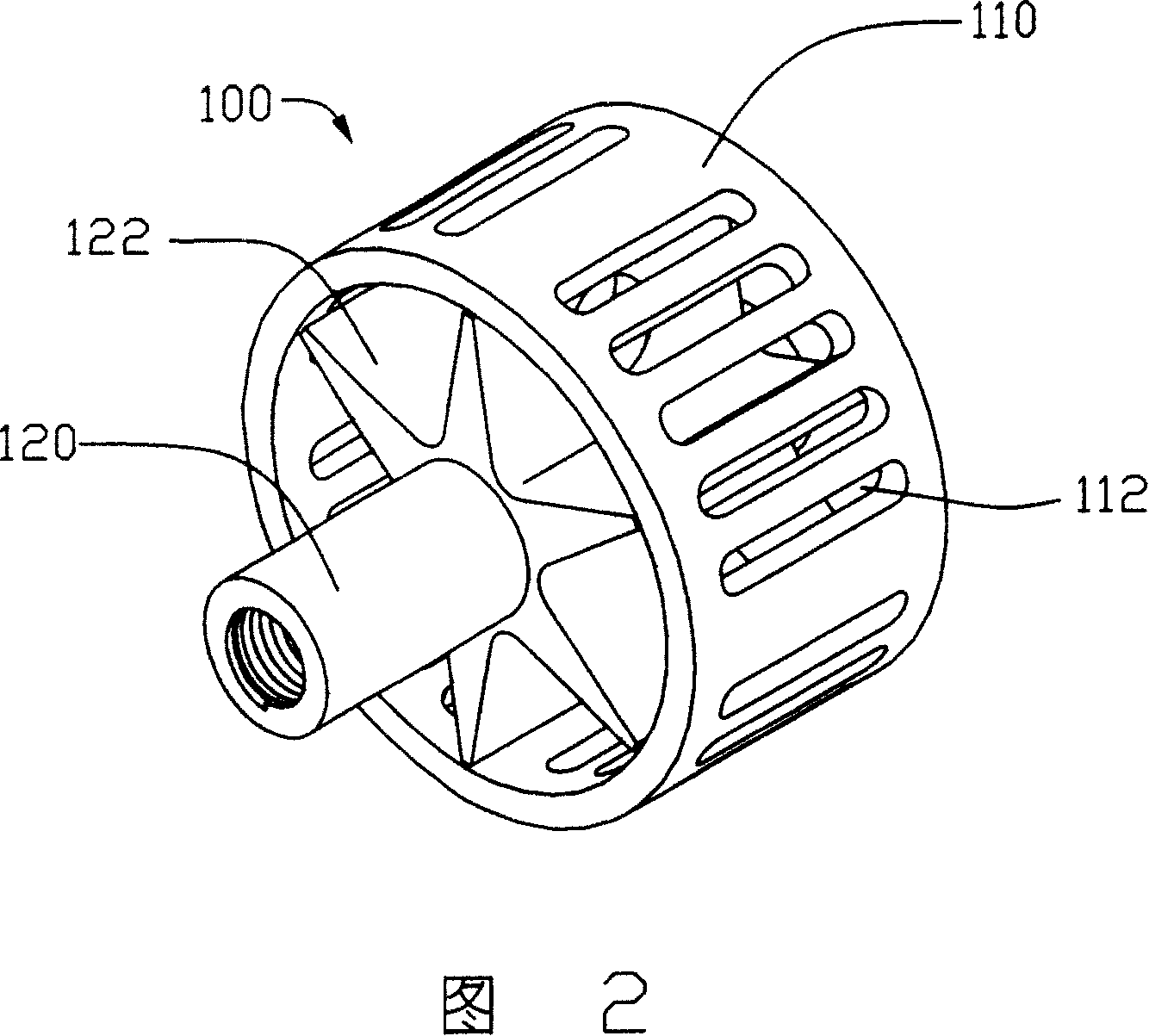

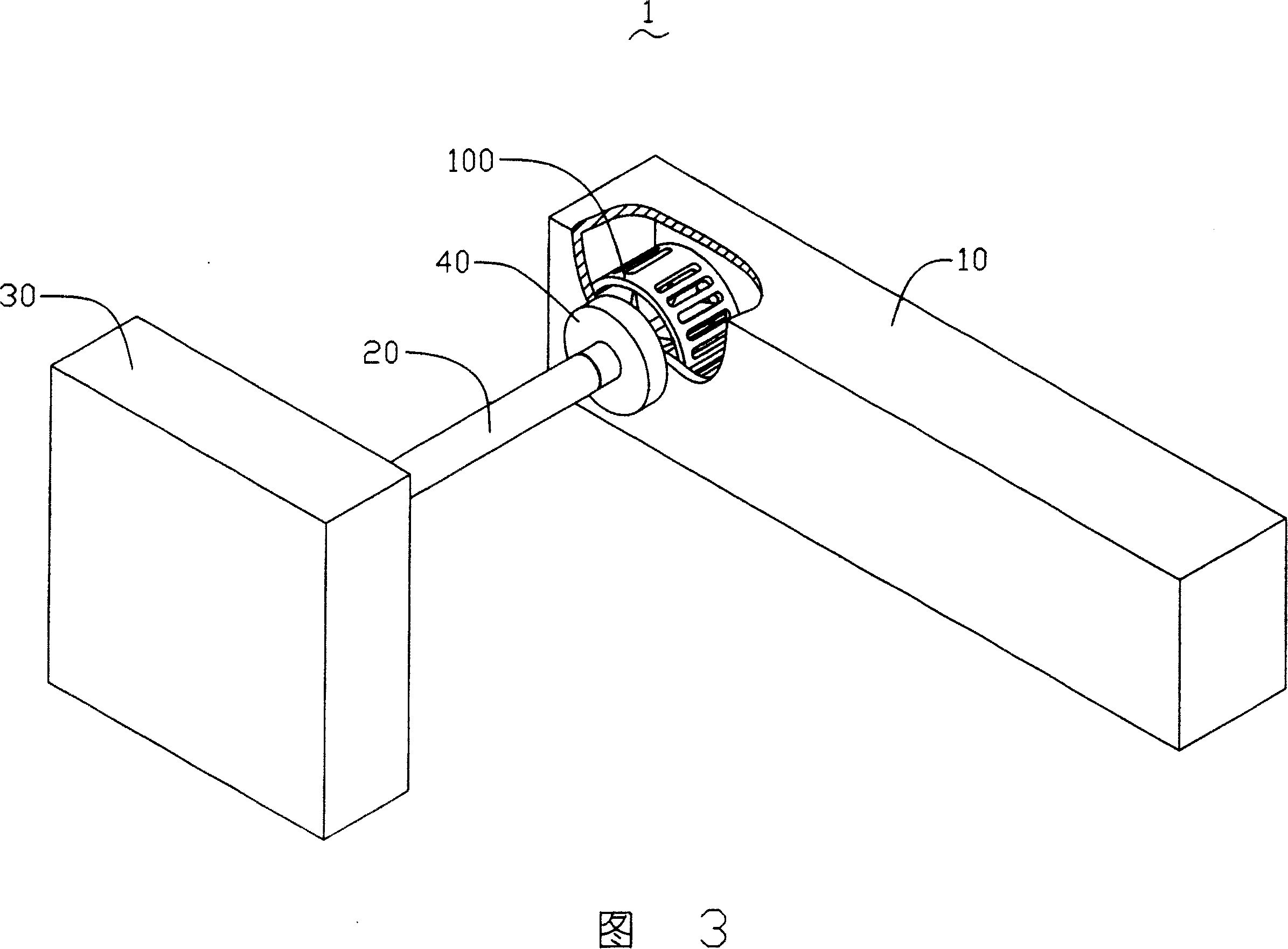

[0012] Please refer to FIG. 1 to FIG. 3 , the heat pipe 1 of the present invention includes a pipe body 10 , a transmission shaft 20 , a driving element 30 and a separation element 100 fixed in the pipe body 10 . The drive element 30 can be selected from a fan, a motor, and the like. The pipe body 10 includes a shell, a capillary structure close to the inner wall of the shell, and a working liquid. The working liquid is usually a liquid substance with a high heat of vaporization, good fluidity, stable chemical properties, and a low boiling point, such as water, ethanol, methanol, Acetone, etc., and adding nanoparticles such as nano-copper particles to the working fluid to improve the thermal conductivity of the working fluid. The capillary structure in the tube body 10 is best in groove type, but other structures such as powder sintering and wire mesh core are also acceptable because nanoparticles are added into the working liquid.

[0013] The transmission shaft 20 is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com