Horizontal well cementing anti-plug fluid and preparation method thereof

A horizontal well and cementing technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of non-abrasion resistance, poor temperature resistance, rubber plug wear, etc., and achieve the effect of preventing aggregation and deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

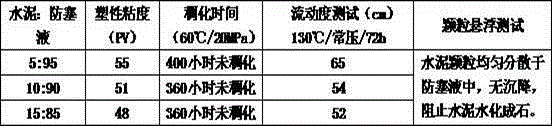

Image

Examples

Embodiment 1

[0027] A horizontal well cementing anti-plug fluid, comprising the following components by weight percentage:

[0028] Low polymerization degree cellulose 3%,

[0029] Fluid loss reducer 2%,

[0030] Slow-release treatment agent 4%,

[0031] Particle dispersant 0.5%,

[0032] The balance is water.

[0033] In the present invention, the degree of polymerization n of the cellulose with a low degree of polymerization is in the range of 60-80.

[0034] In the present invention, the cellulose with a low degree of polymerization may be hydroxymethyl cellulose or polyanionic cellulose, but it is not limited thereto.

[0035] In the present invention, the fluid loss control agent may be xanthyl phenolic resin or AMPS polymer, but it is not limited thereto.

[0036] In the present invention, the slow-release treatment agent can be EDTA, and its chemical formula of EDTA is [C 10 h 16 N 2 o 8 ]; it can also be 2-hydroxyphosphonoacetic acid, but not limited thereto.

[0037] In ...

Embodiment 2

[0041] A horizontal well cementing anti-plugging fluid is characterized in that it comprises the following components by weight percentage:

[0042] Low polymerization degree cellulose 5%,

[0043] Fluid loss reducer 4%,

[0044] Slow-release treatment agent 6%,

[0045] Particle dispersant 1%,

[0046] The balance is water.

[0047] A method for preparing a horizontal well cementing anti-clogging fluid, comprising: first dissolving cellulose with a low degree of polymerization into water according to the weight percentage of the components, stirring to make it dissolve evenly, and fully hydrating after standing for 40 minutes; The fluid loss agent, the slow-release treatment agent and the particle dispersant are stirred for 30 minutes to prepare a horizontal well cementing anti-clogging fluid.

Embodiment 3

[0049] A horizontal well cementing anti-plugging fluid is characterized in that it comprises the following components by weight percentage:

[0050] Low polymerization degree cellulose 4%,

[0051] Fluid loss reducer 3%,

[0052] Slow-release treatment agent 5%,

[0053] Particle dispersant 0.8%,

[0054] The balance is water.

[0055] A method for preparing a horizontal well cementing anti-clogging fluid, comprising: dissolving cellulose with a low degree of polymerization into water according to the weight percentage of the components, stirring to make it dissolve evenly, and fully hydrating after standing for 30 minutes; The fluid loss agent, the slow-release treatment agent and the particle dispersant are stirred for 20 minutes to prepare a horizontal well cementing anti-clogging fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com