Float ball valve for supplying and draining oil in multifunctional sealed oil tank

A sealed oil tank, multi-functional technology, applied to multi-way valves, valve details, valve devices, etc., can solve the problems of large upward inclination angle of the connecting rod, increased friction of the valve core, and impossibility of oil discharge, so as to avoid installation errors , increase the effect of safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

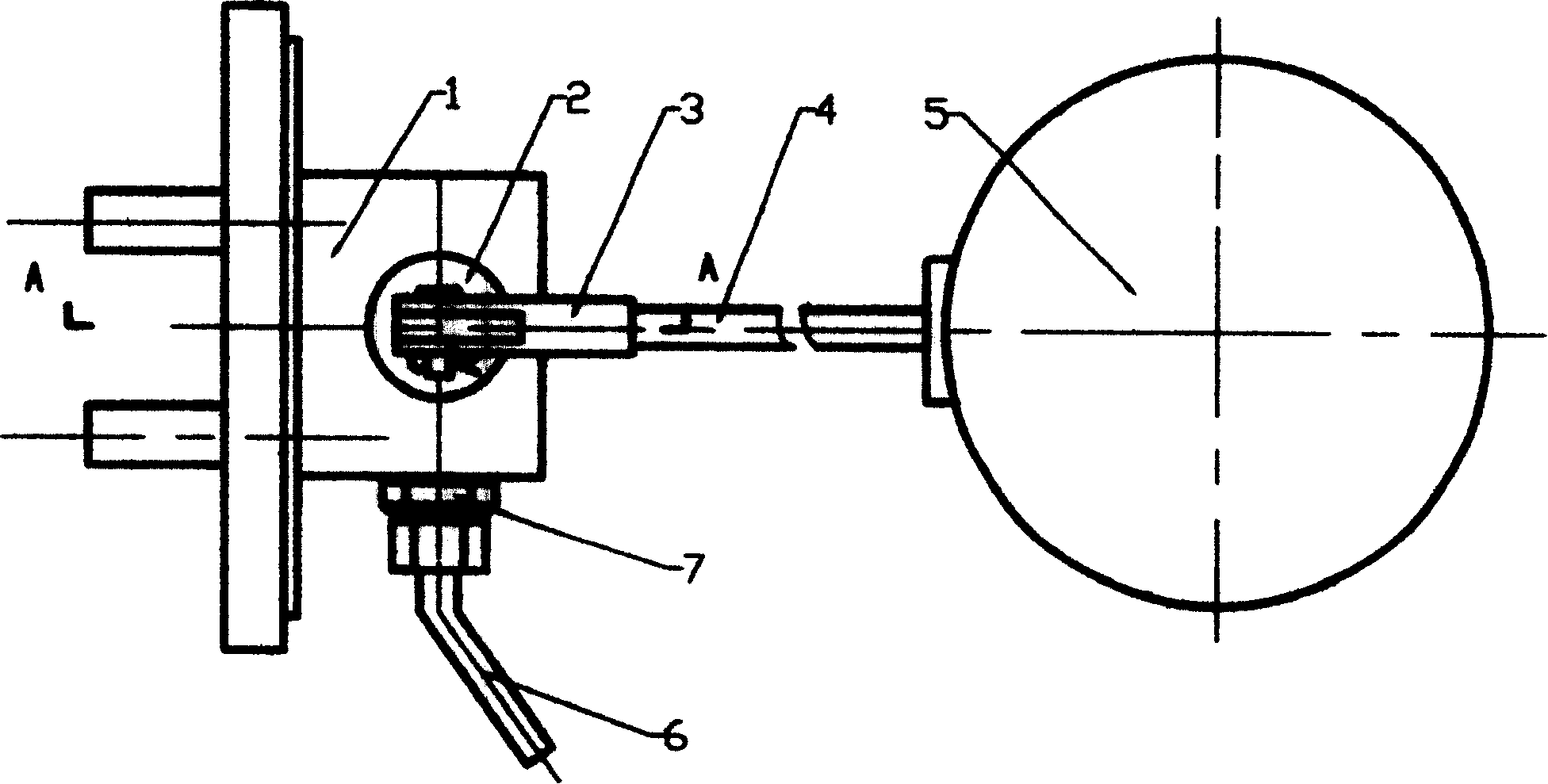

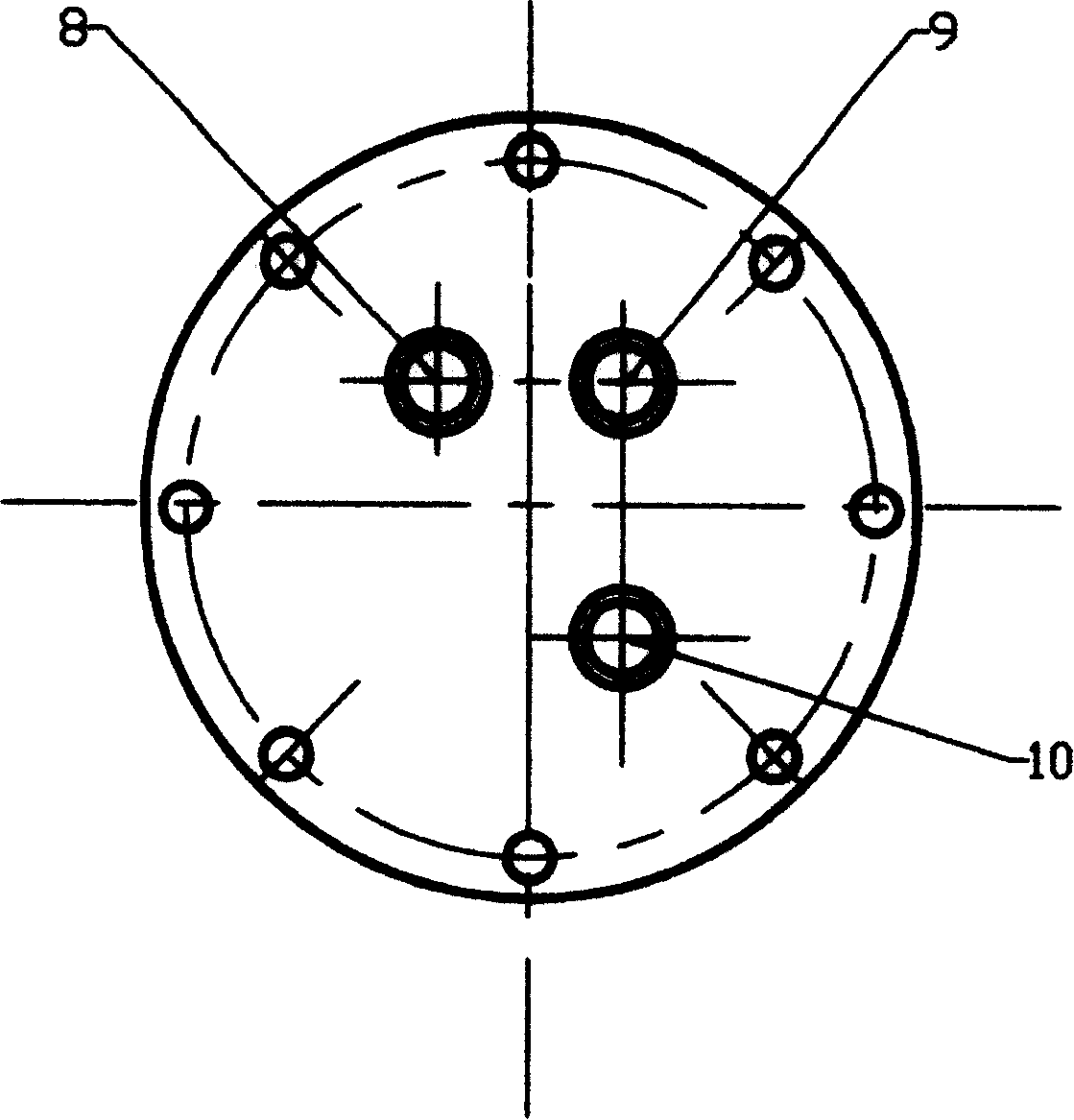

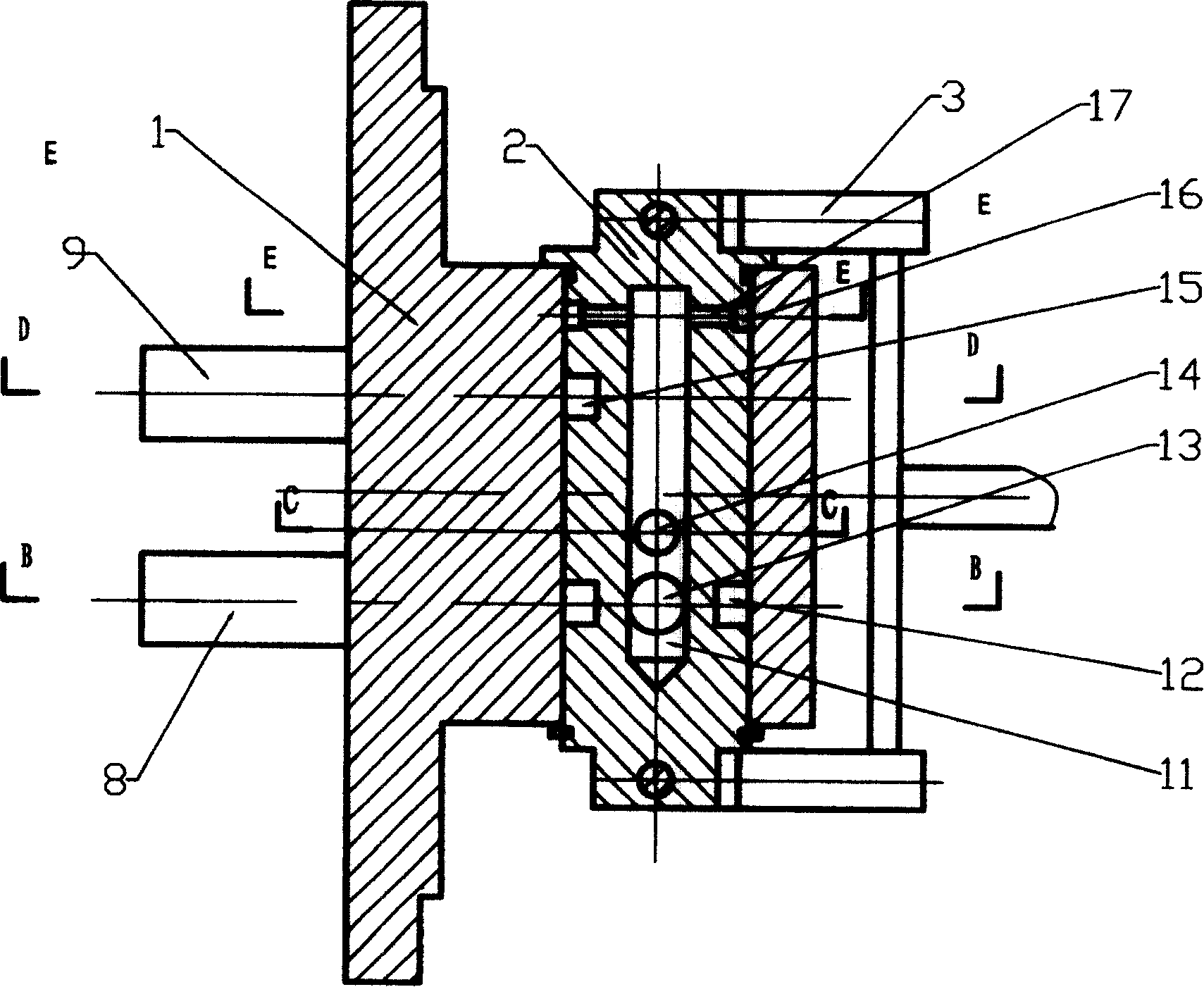

[0016] Such as Figure 1-6 As shown, a multi-functional sealed oil tank replenishment and discharge oil floating ball valve includes a valve body 1, a valve core 2, a connecting rod frame 3, a connecting rod 4, a floating ball 5, an oil discharge guide pipe 6, and a check door 7. It is characterized in that the left and right sides of the end face of the valve body 1 and the right side of the lower part are respectively provided with an oil supply pipe 8, an oil discharge pipe 9, and a power oil discharge pipe 10 (such as figure 2shown). Among them, the fuel supply pipe 8 is connected to the outlet of the oil pump of the airside fuel supply system, the oil discharge pipe 9 is connected to the main oil tank of the oil source of the airside fuel supply system, and the power oil discharge pipe 10 is connected to the outlet of the oil pump of the hydrogen side fuel supply system through an external valve. The inside of the valve body is provided with a second oil supply hole 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com