LCD backlighting inverter circuit and LCD

A liquid crystal display and inverter technology, which is applied in the field of liquid crystal display backlight inverter circuits, can solve problems such as limiting current startup characteristics, limiting dimming range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

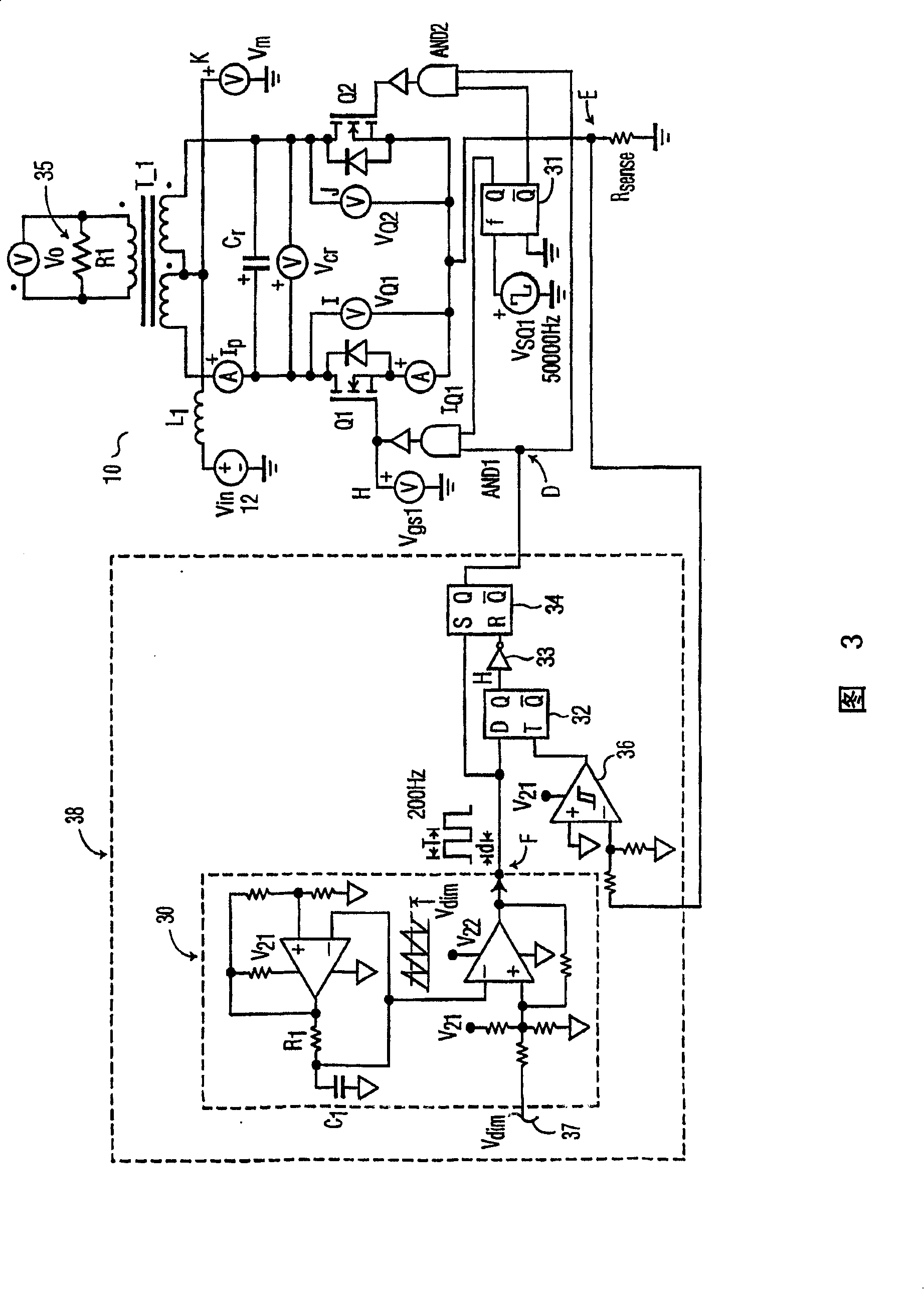

[0016] Returning now to the drawings, in which like reference numerals indicate like or identical elements throughout the several schematic diagrams, FIG. 3 illustrates an electronic liquid crystal display backlight inverter circuit 10 in accordance with an embodiment of the present invention. It is foreseeable that the improved circuit according to the present invention will be used in liquid crystal display backlighting applications.

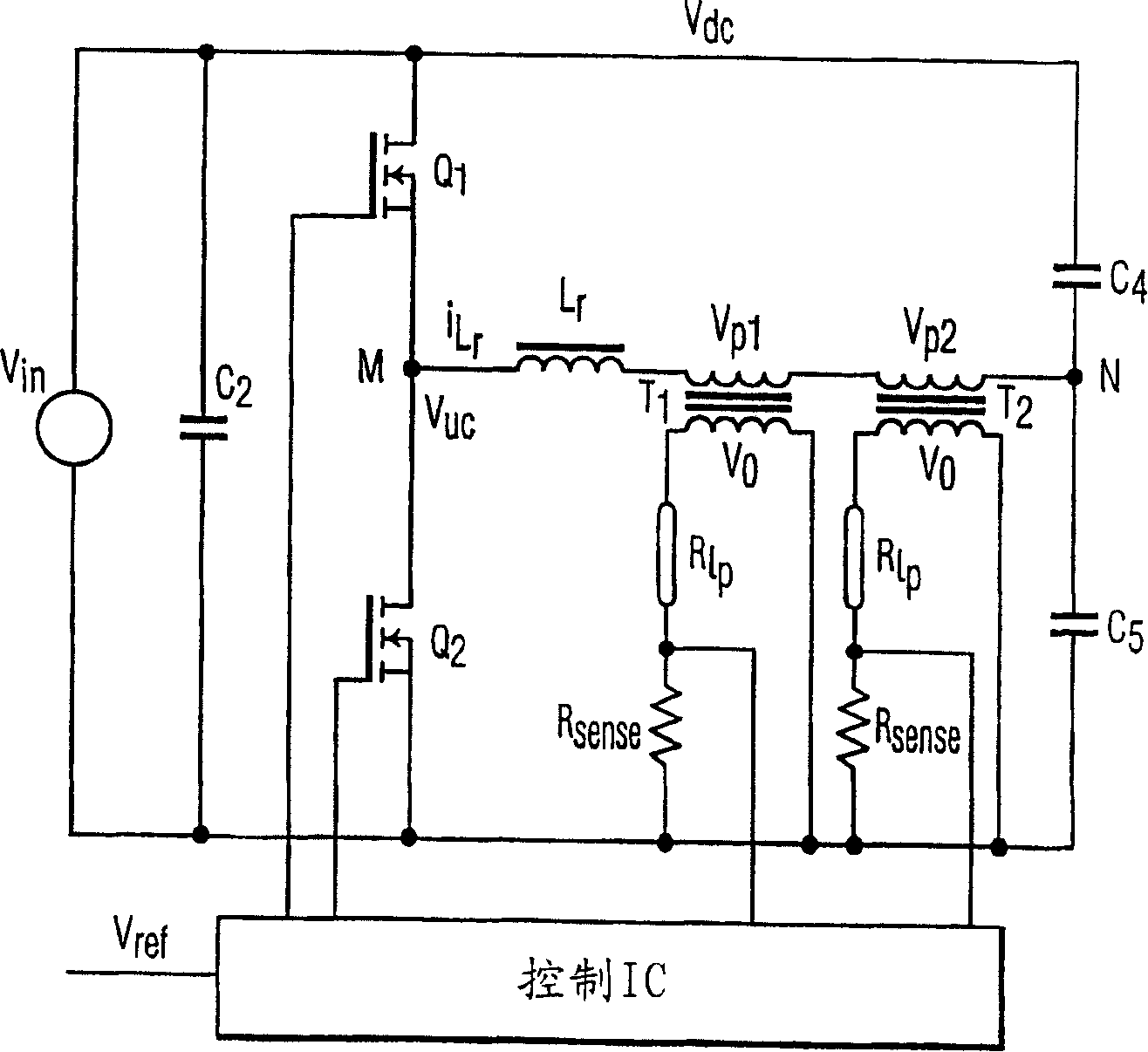

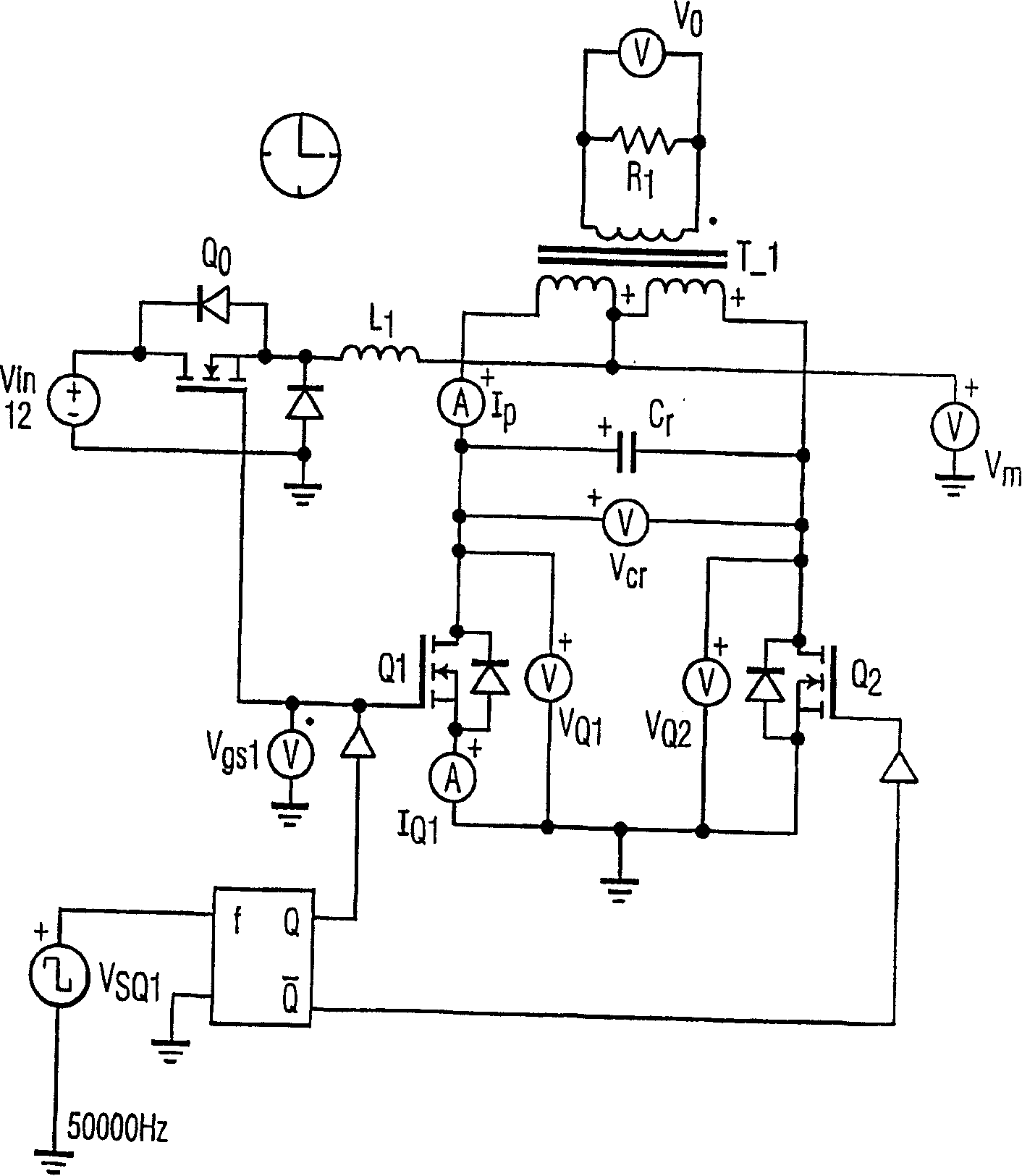

[0017] The LCD backlight inverter circuit 10 according to the present invention is a voltage-fed push-pull resonant circuit for the operation of the load 35 . The load 35 shown in Figure 3 is of the resistive type, but the load could be, but is not limited to, a cold cathode type fluorescent lamp (eg CCFL). For example, light from load 35 may be used to illuminate a computer's liquid crystal display flat panel display (not shown). The LCD backlight inverter circuit 10 may be powered by a conventional AC power source, which is then rectified a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com