Inorganic paint composition

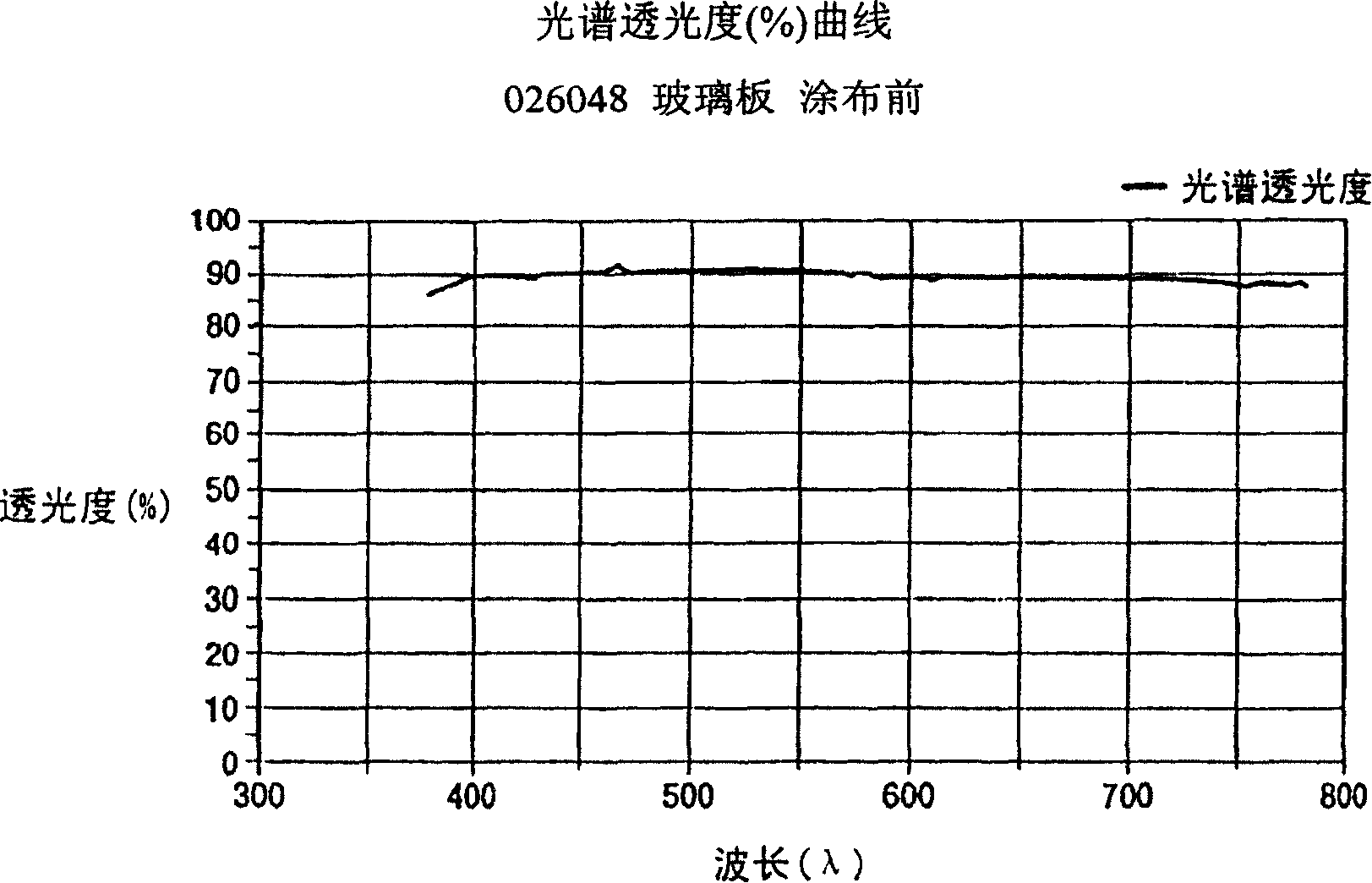

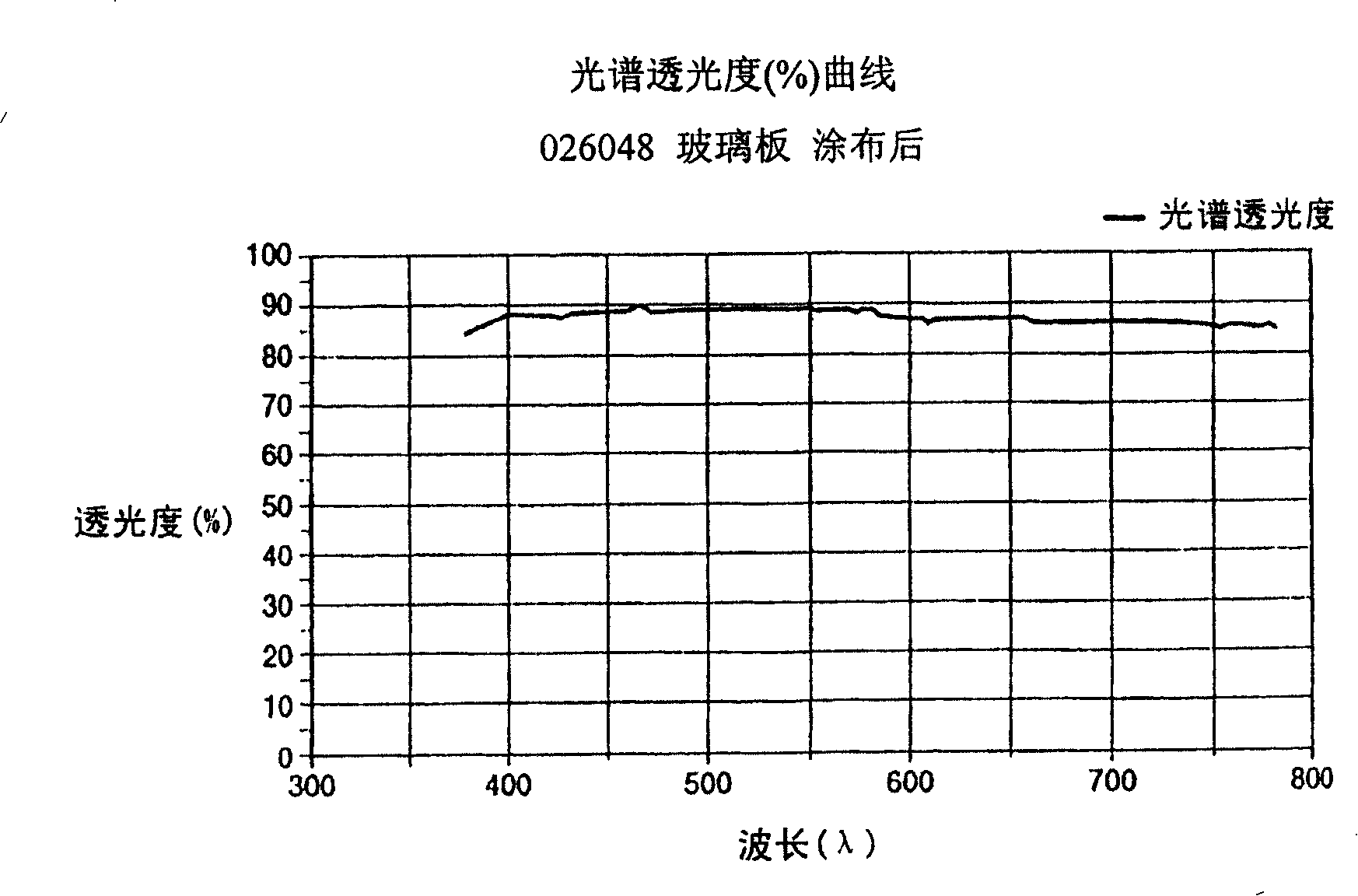

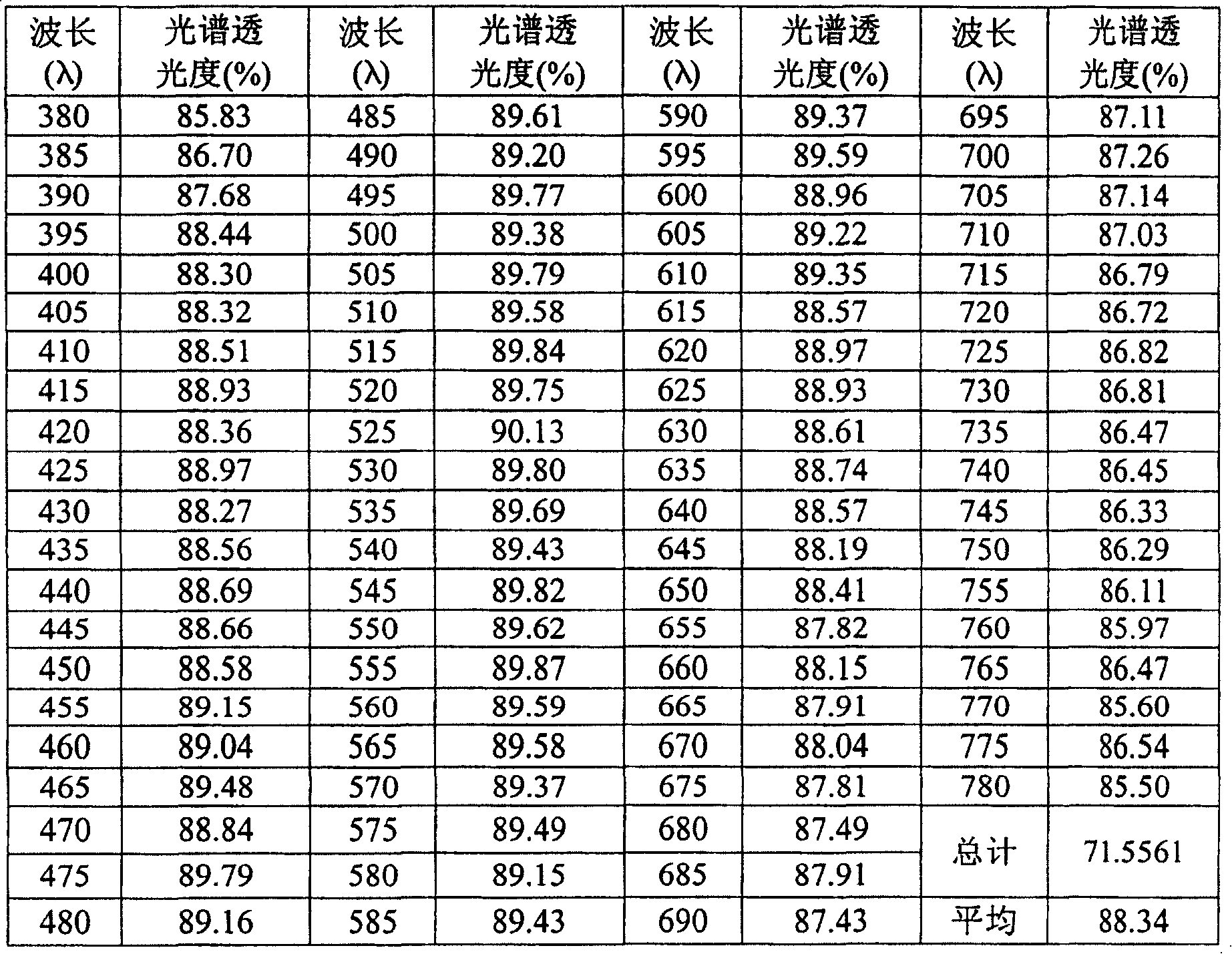

A technology of inorganic coatings and compositions, which can be applied in the directions of alkali metal silicate coatings, coatings, and heat-collecting element reinforcement, and can solve problems such as insufficient light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be described below.

[0013] The inorganic coating composition of the present invention is prepared by adding borate to alkali metal silicate, and mixing thereto flaky metamorphic transparent silica having a thickness of 0.01 to 0.5 microns and a surface diameter of 2 to 5 microns.

[0014] Titanium dioxide fine particles may be mixed with the above composition.

[0015] Alkali metal silicates are silicates such as lithium silicate, sodium silicate and potassium silicate, and are solidified by a syneresis reaction and gelled by adding borates as described below.

[0016] Examples of borates include magnesium borate, calcium borate, barium borate, strontium borate, zinc borate, and aluminum borate. These borates can be used alone or as a mixture.

[0017] An example of a silicate having the above-mentioned properties is commercially available Sun LovelyLFS (trade name, produced by Asahi Glass Co., Ltd.), which is sold as a slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com