Pressure sensor employing thickness-cutting resonance for quartz crystal board

A pressure sensor, quartz crystal technology, applied in the field of pressure sensors, can solve problems such as low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

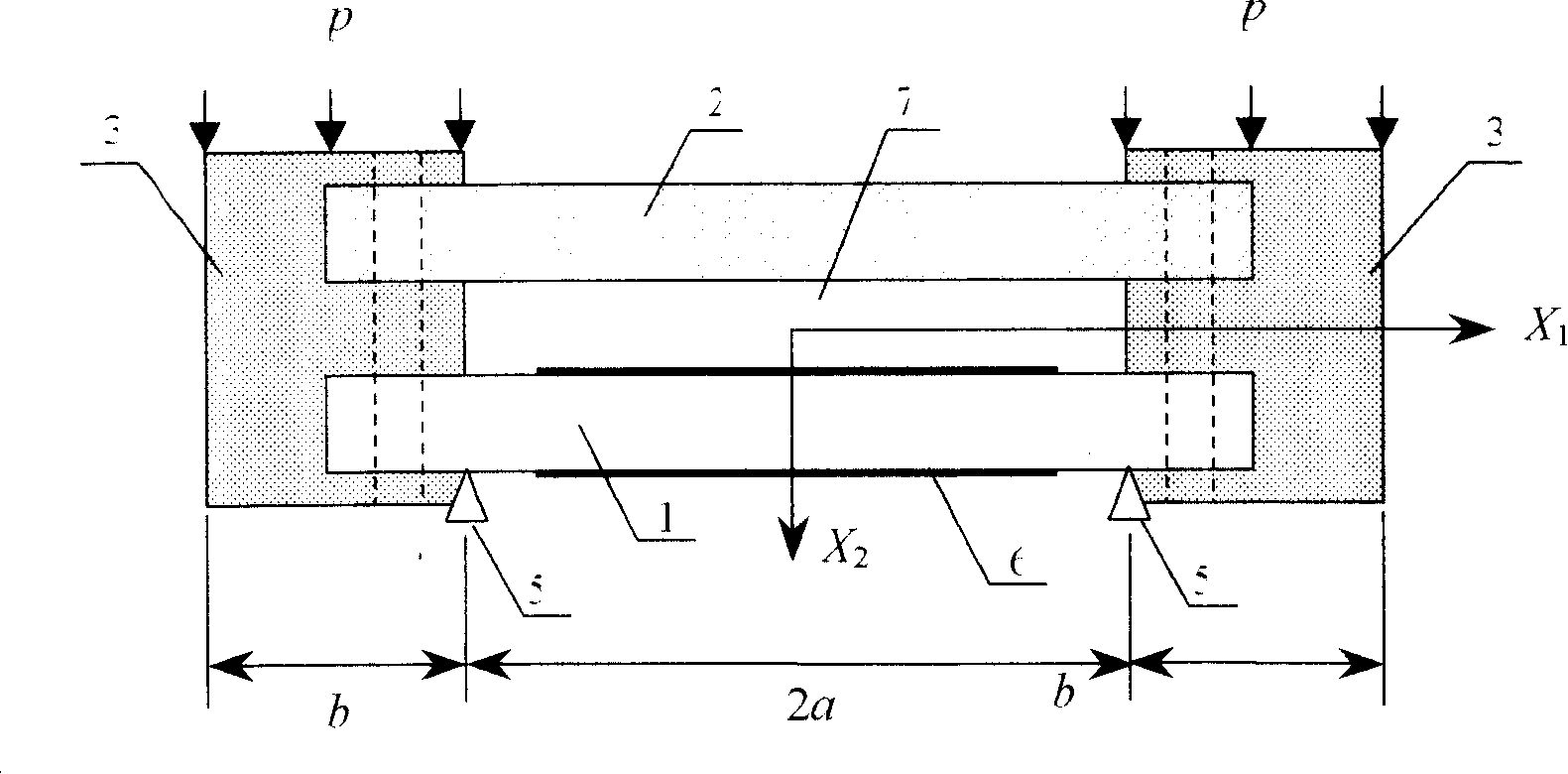

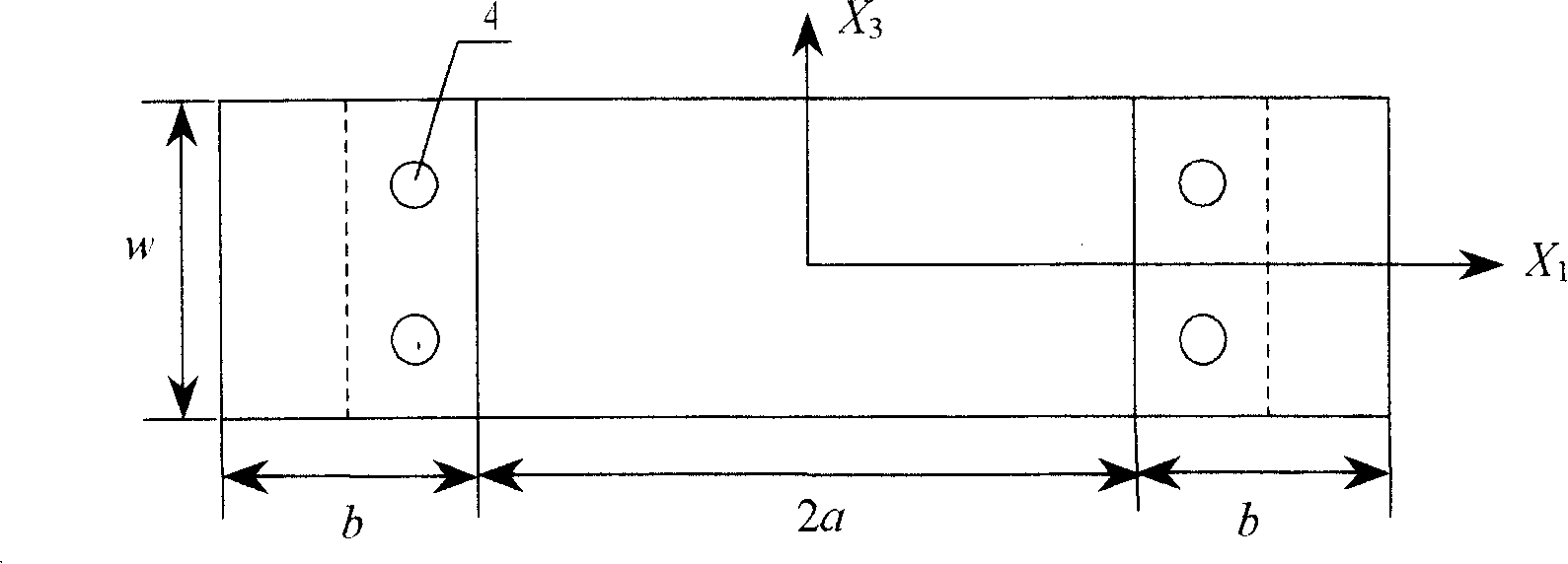

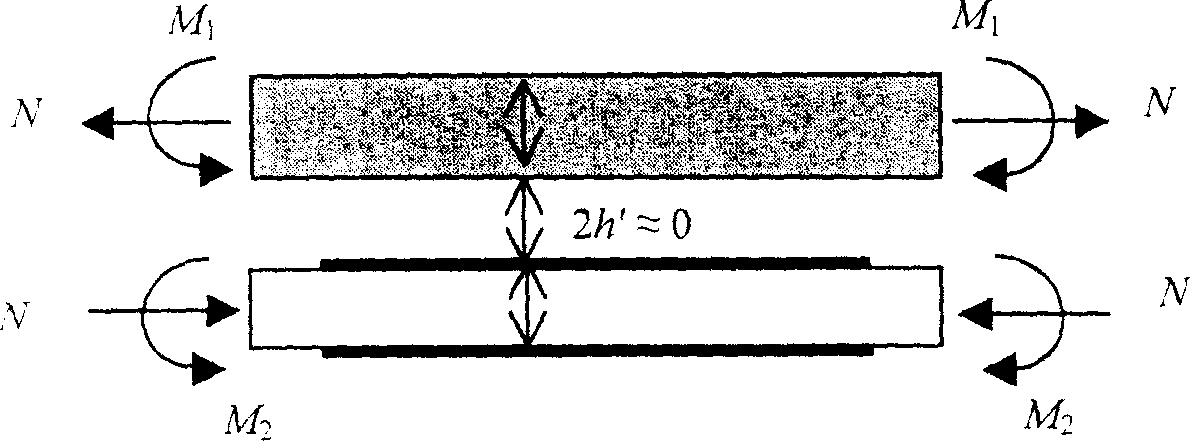

[0028] [implementation mode] such as figure 1 and figure 2 As shown, the invention consists of a quartz crystal plate 1, an auxiliary metal plate 2 and an end plate 3 for fixing the second plate and bearing the environmental pressure p, the end plate 3 being much harder than the plates 1 and 2. When connecting the end plate 3 with the quartz crystal plate 1 and the auxiliary metal plate 2, in addition to bonding them with super glue along the interface between them, four bolts 4 are also used to fasten them together. The entire plate structure is fixed on the two supports 5, so that under the action of p, the combined quartz crystal-auxiliary metal plate structure located between the two supports is in a pure bending state. In addition, the upper and lower surfaces of the quartz crystal plate are coated with thin-layer silver electrodes 6, and there is a micro-gap 7 between the quartz crystal plate and the auxiliary metal plate. Select Cartesian coordinate system X 1 x 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com