Aluminium-casing lithium ion cell core with antiexplosion film

A technology of lithium ion and explosion-proof membrane, which is applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems of large investment in fixed assets, high equipment requirements, and high production costs, and achieves good consistency in mass production and low impact on battery weight. The effect of small opening pressure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

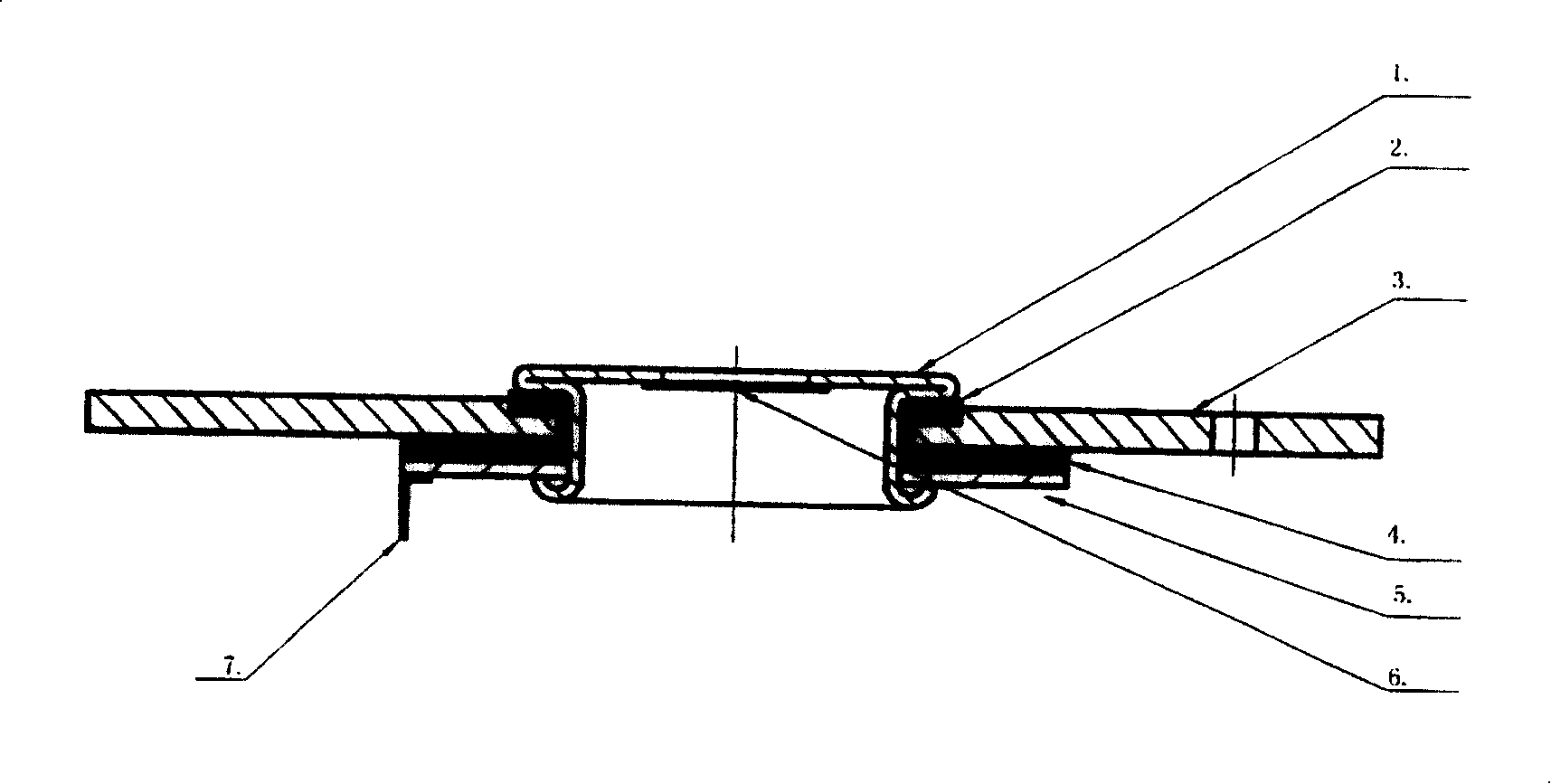

[0016] For the ICP183665AR type aluminum shell lithium-ion battery, adopt the structure shown in the attached figure, firstly manufacture the stainless steel hollow rivet, punch out the explosion-proof hole with a diameter of 4mm on the flat bottom of the rivet, and vacuum-braze the rolled red copper with a thickness of 12 microns on the edge of the hole Foil 6, using NBi-2 amorphous solder, the rivet rod after brazing is placed in sequence with sealing insulating gasket 2, large aluminum cover plate 3, sealing insulating gasket 4, metal pressure plate 5, and then riveted, the riveted cover plate After the tight fit with the aluminum shell, laser welding is used to seal it, and then subsequent processes such as vacuum drying, electrolyte injection, and chemical formation are carried out to manufacture 183665 aluminum shell lithium-ion batteries with explosion-proof membranes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com