Hydraulic bidirection return stroke damper

A shock absorber and return technology, which is applied in the direction of liquid shock absorber, shock absorber, shock absorber, etc., can solve the problems of slow wheel reset, poor vibration damping effect, fast response speed, etc., and achieve strong flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

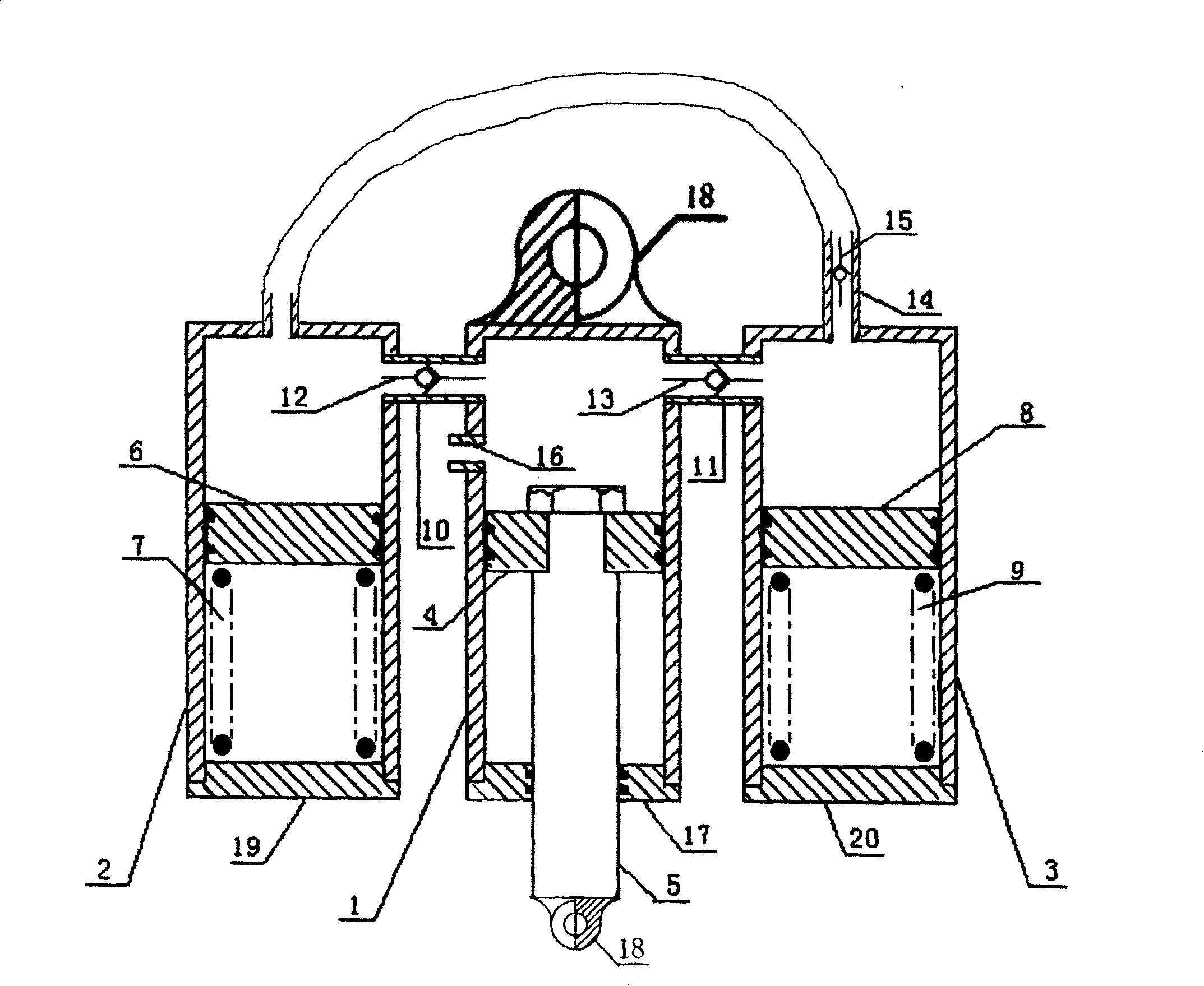

[0018] exist figure 1 In the shown embodiment, the compression cylinder 2, stretch cylinder 3 and vibration cylinder 1 are separately installed in different places, and the connection pipe 10 communicates between the vibration cylinder 1 and the compression cylinder 2, and there is a one-way valve 12 in the connection pipe 10, Vibrating cylinder 1 is communicated with stretching cylinder 3 by connecting pipe 11, and there is check valve 13 in connecting pipe 11, and between compression cylinder 2 and stretching cylinder 3, is connected by connecting pipe 14, and there is check valve 15 in connecting pipe 14.

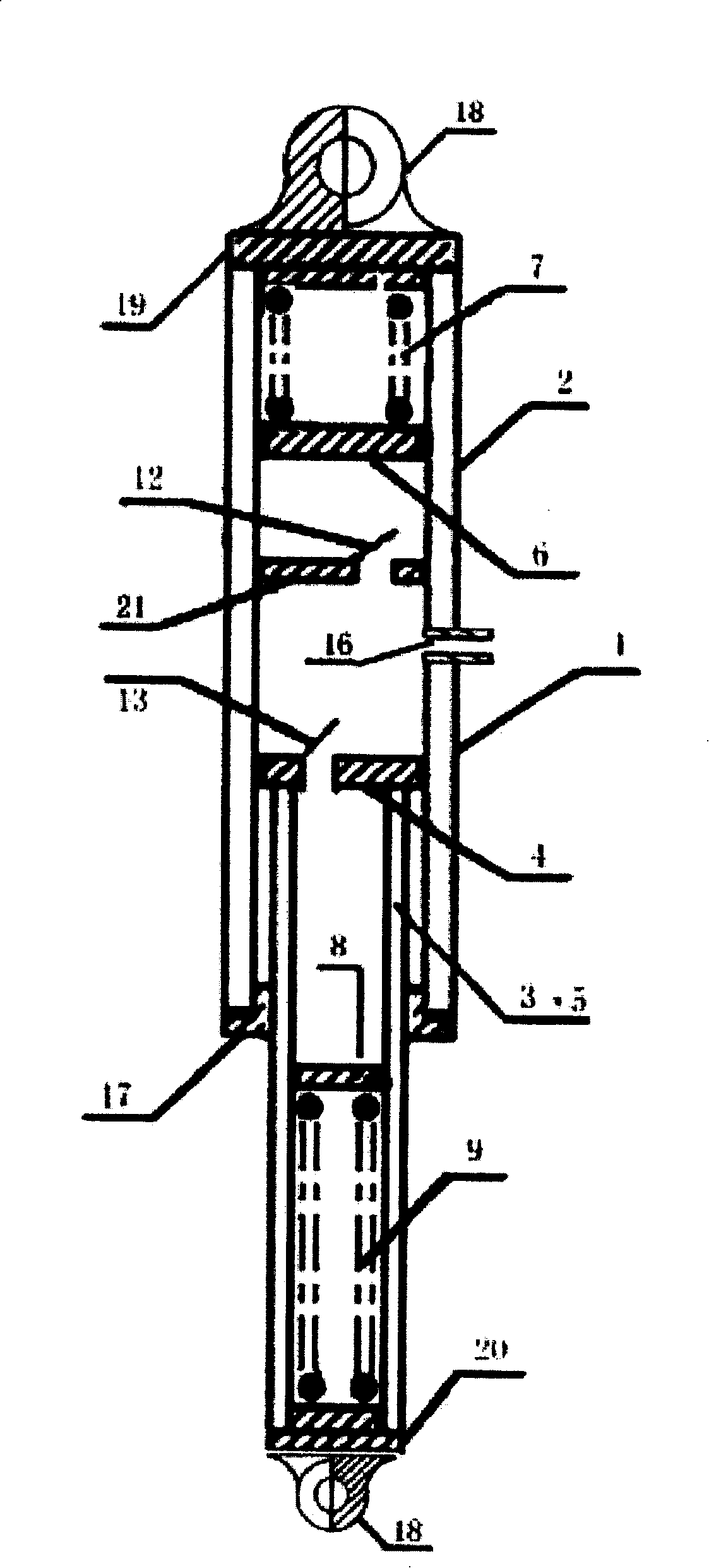

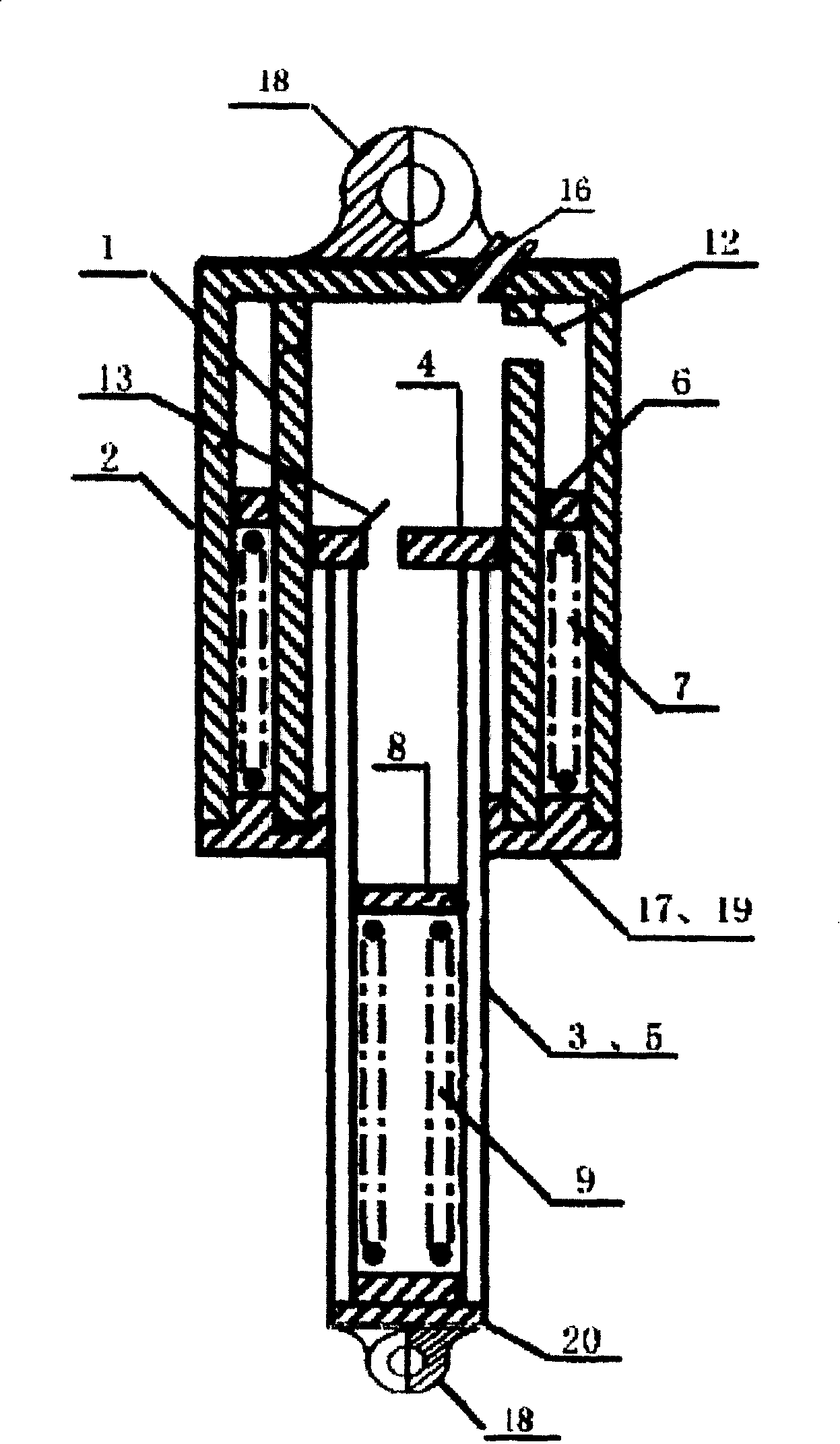

[0019] exist figure 2 In the embodiment of the present invention, the vibrating cylinder 1 and the compression cylinder 2 are combined into one, separated by a partition 21 in the middle, the stretching cylinder 3 reaches the piston rod 5 miles, the one-way valve 12 is installed on the partition 21, and the one-way valve 13 is installed to piston assembly 4.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com