Film semiconductor device, its manufacturing method, electro-optical device, and electronic apparatus

A technology of thin film semiconductor and manufacturing method, which is applied in the field of manufacturing of electronic machines and capacitive elements, and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0034] (Overall configuration of liquid crystal device)

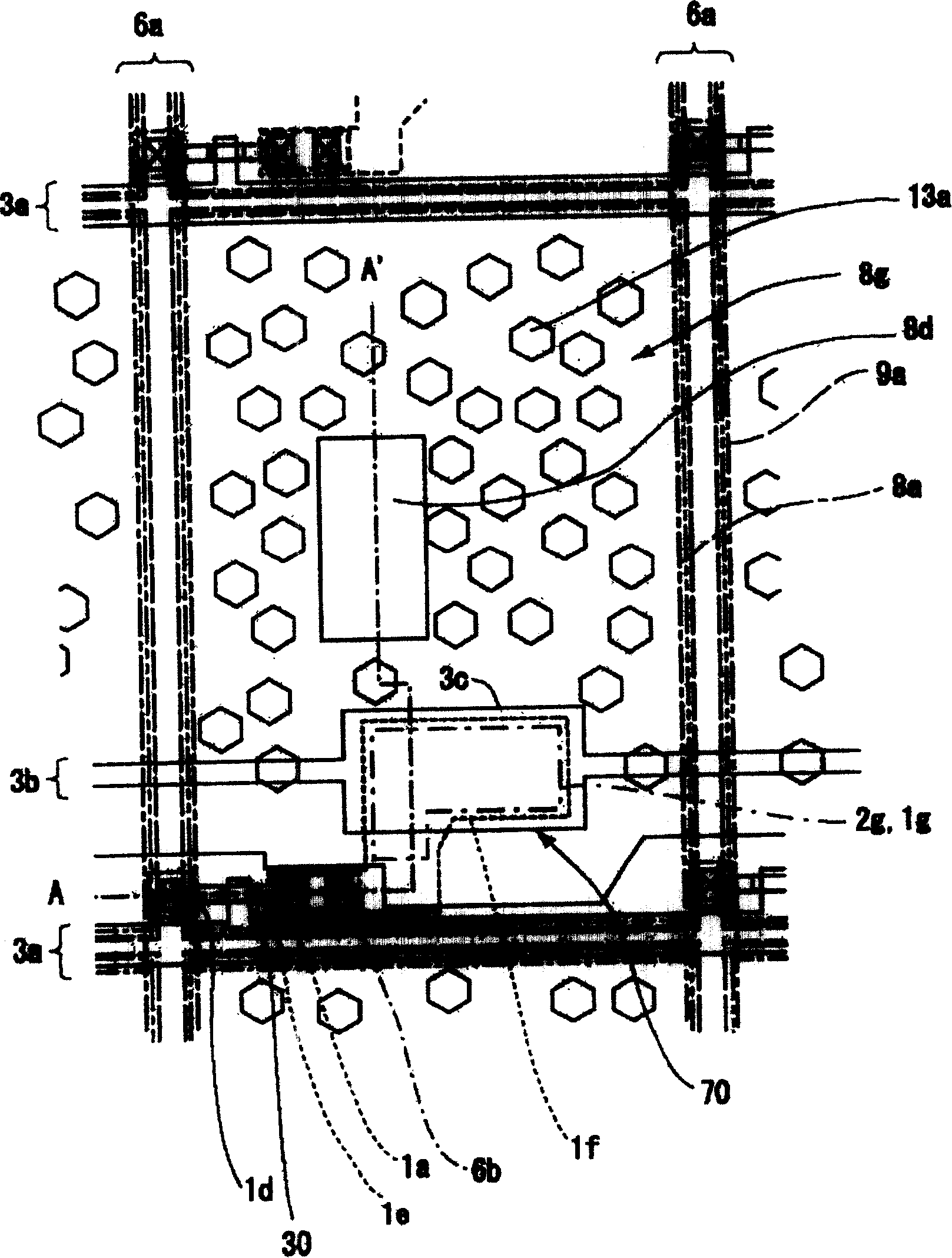

[0035] figure 1 (A) and (B) are plan views of the liquid crystal device and components formed thereon viewed from the side of the counter substrate, and a plan view including the counter substrate, respectively. figure 1 (A) H-H' sectional view.

[0036] exist figure 1In (A) and (B), in the liquid crystal device 100 (electro-optical device), the TFT array substrate 10 (thin film semiconductor device) and the opposing substrate 20 are coated with a sealing material 107 along the edge of the opposing substrate 20 ( figure 1 (A) The slashed area in the lower right) fit. Furthermore, liquid crystal 50 as an electro-optic substance is held between the TFT array substrate 10 and the counter substrate 20 . On the outer peripheral side of the TFT array substrate 10, a data line driving circuit 101 is formed to partially overlap the sealing material 107 on the side of the substrate side 111, and a scanning line driving circu...

Embodiment approach 2

[0074] (Structure of TFT array substrate)

[0075] Figure 8 represents the TFT array substrate of the electro-optical device according to Embodiment 2 of the present invention, and is equivalent to image 3 An explanatory diagram of the cross-section at the position of the A-A' line. Figure 9 It is a cross-sectional view showing the structure of TFTs constituting peripheral circuits such as a scanning line driving circuit and a data line driving circuit in the TFT array substrate of the electro-optical device according to the present embodiment. In addition, since the basic configuration of the electro-optical device of this embodiment is the same as that of Embodiment 1, common parts are given the same reference numerals and their descriptions are omitted.

[0076] Such as Figure 8 As shown, in the present embodiment, also in the storage capacitor 70, the recessed portion 2g (first recessed portion) having the film thickness of the dielectric film 2c thinner than the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com