Cooled high intensity gas discharge lamp

A technology of high-pressure gas and discharge lamps, which is applied in the direction of high-pressure discharge lamps, gas discharge lamps, parts of gas discharge lamps, etc., which can solve problems such as difficulties, limitations, and increased lamp power, so as to reduce cooling, increase lamp power, and prevent The effect of mercury condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

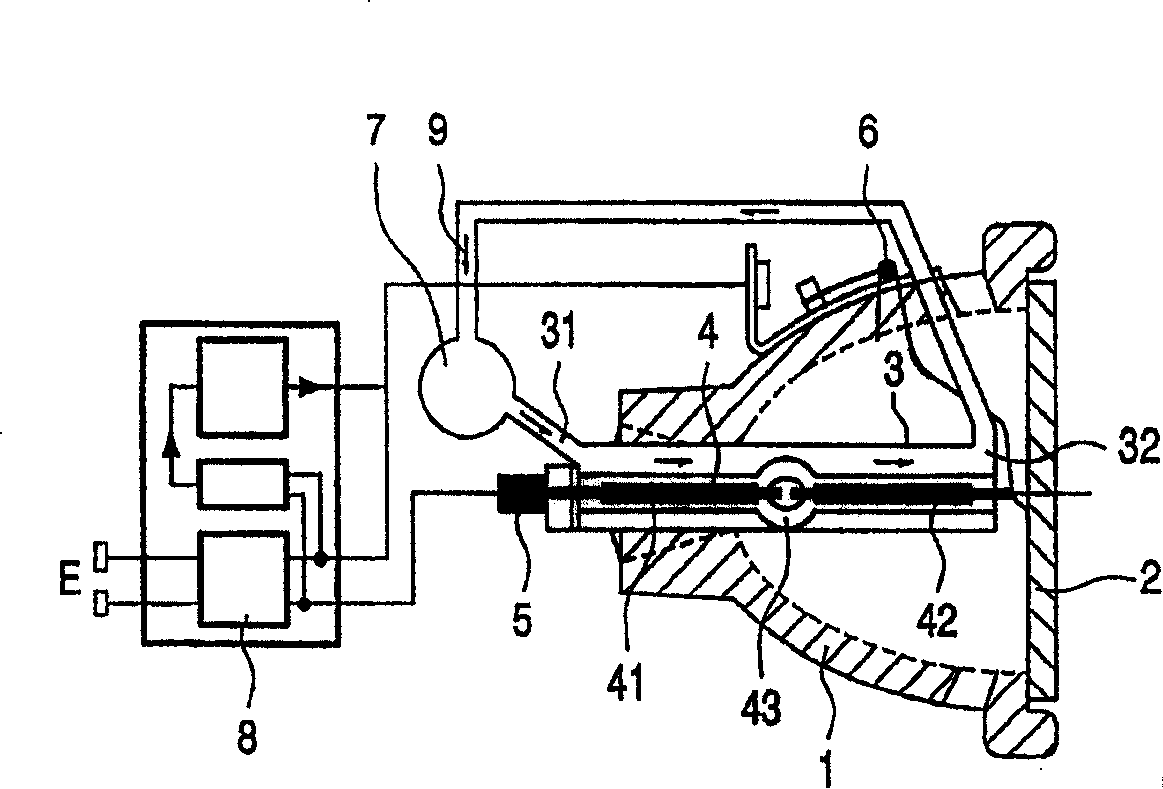

[0033] figure 1 A UHP lamp according to the invention is shown schematically in cross-section in a horizontal installation position. The UHP lamp has a reflector 1 , the opening of which is preferably closed by a front glass 2 . Windshield 2 forms a light exit surface and serves to protect the surroundings in the event of damage to the lamp. Windshield 2 can also be designed as a filter glass for the light generated.

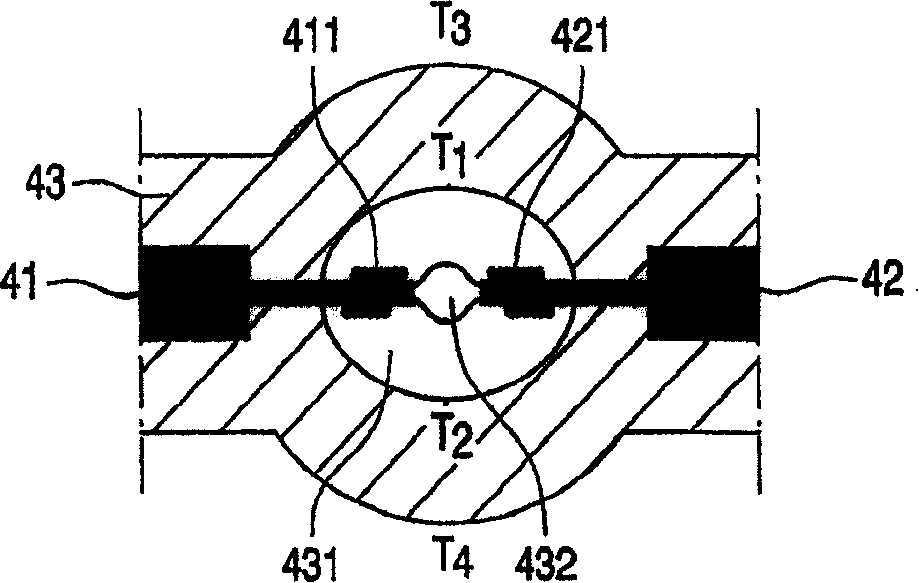

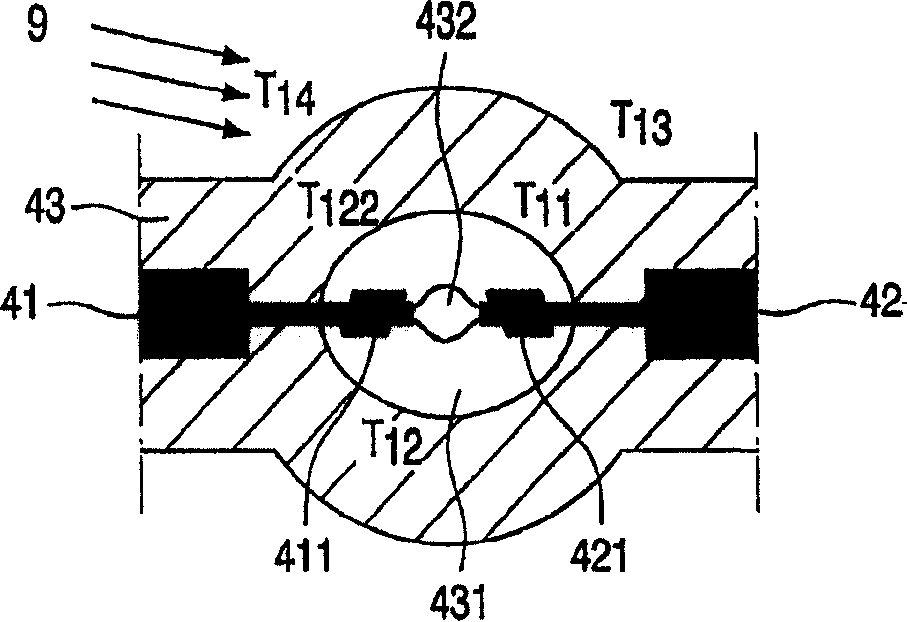

[0034] An electrode arrangement 4 protrudes into the housing 1 from an opening opposite the end of the reflector housing 1 . The electrode arrangement 4 basically comprises a first electrode 41 and a second electrode 42 which are located in a bulb 43 and between opposite tips of the electrodes cause an arc discharge in a discharge chamber 431 of the bulb 43 . The other ends of the electrodes 41, 42 are respectively connected to the electric contacts 5, 6 of the lamp, and the power supply device 8 inputs the feed voltage required for lamp operation through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com