Homogeneous electric welding rod/flame welding wire for welding gray cast iron and ductile cast-iron

A technology for ductile iron and welding electrodes, which is applied in the direction of welding/cutting media/materials, welding media, welding equipment, etc., can solve problems such as high content, poor plasticity, inability to meet color consistency, and performance matching comprehensive performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in combination with specific embodiments.

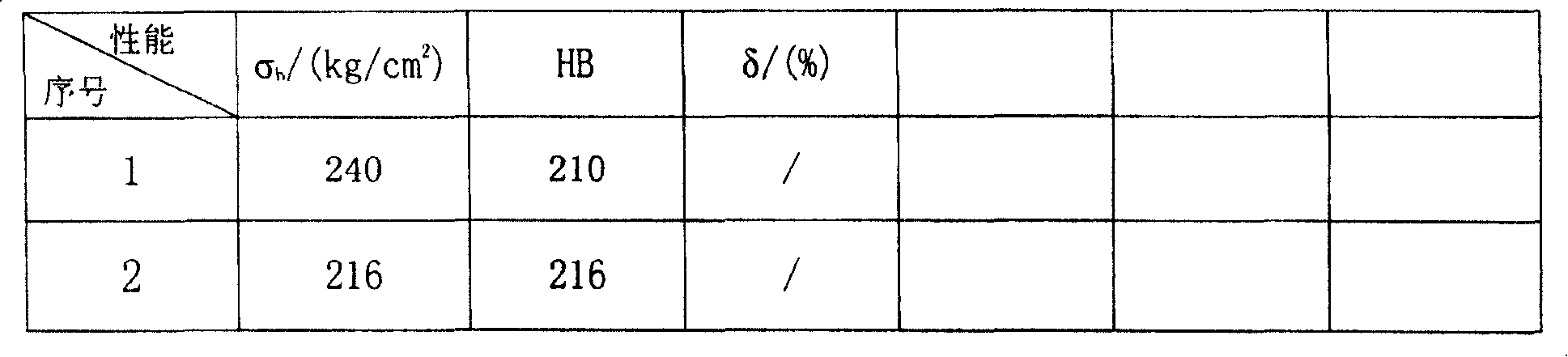

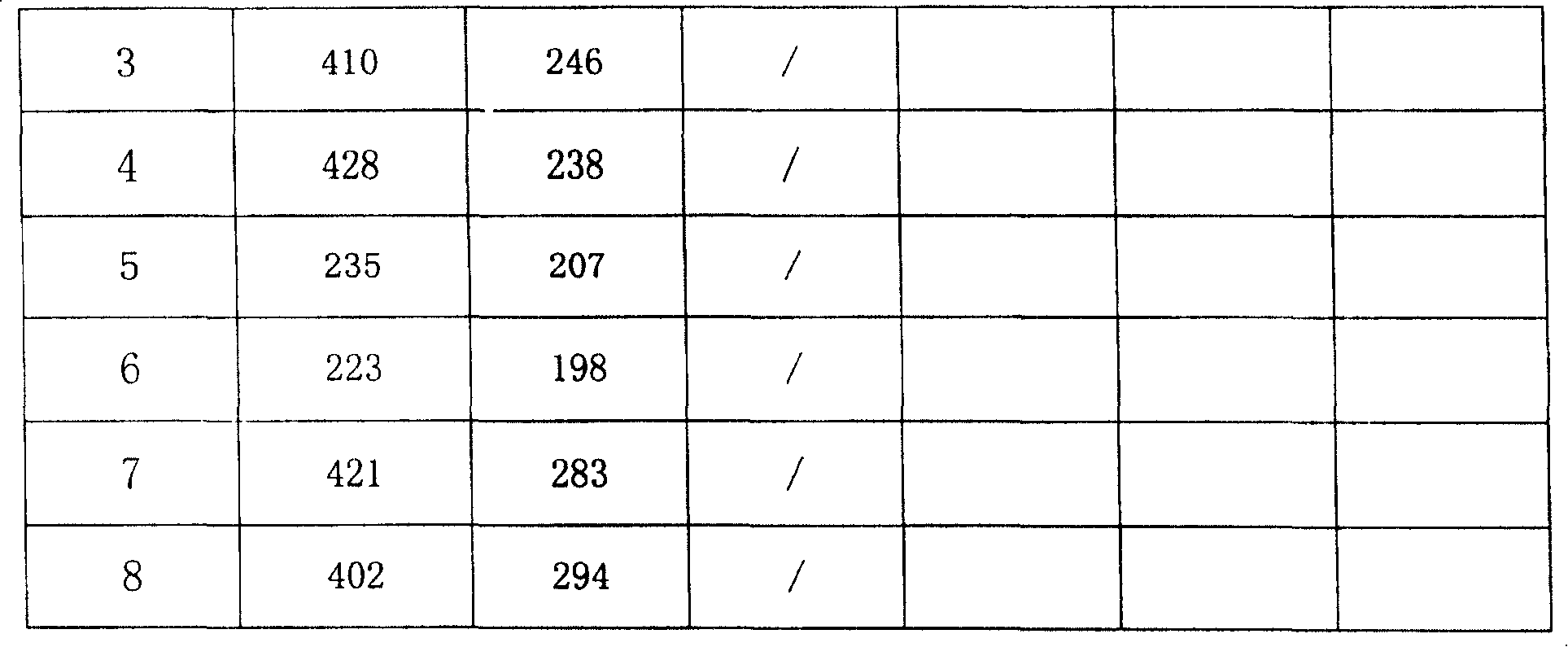

[0018] The homogeneous electric welding rod / gas welding wire used for cold welding or low-temperature welding of gray cast iron and ductile iron adopts an electric furnace to melt molten iron with low impurity content, and uses Ti, Bi, Ba, Ce and other alloy elements to weld the welding core / welding wire Multivariate micro-alloying treatment, after furnace spheroidization and inoculation treatment, cast into nodular cast iron core or gas welding wire; without furnace spheroidization, cast into gray cast iron core or gas welding wire. Gray cast iron gas welding wire, composed of the following components by weight percentage: C3.6%~4.0%, Si3.6%~4.6%, Mn0.2%~0.4%, S# Ferrosilicon 15%~25%, 30 # Silicon-calcium alloy 3%-7%, aluminum powder 3%-7%, iron powder 3%-7%, white clay 10%-15%, sodium carbonate 0.8%-1.2%, dried to make gray cast iron welding rod . The ductile iron cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com