Method for manufacturing nylon/polyester compound ultra-fine fibre cleaning cloth

A production method and superfine fiber technology, applied in cleaning machinery, cleaning equipment, fiber treatment, etc., can solve the problem of color fastness not reaching level 4, unsatisfactory pretreatment effect, water marks and scratches on the surface of objects And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

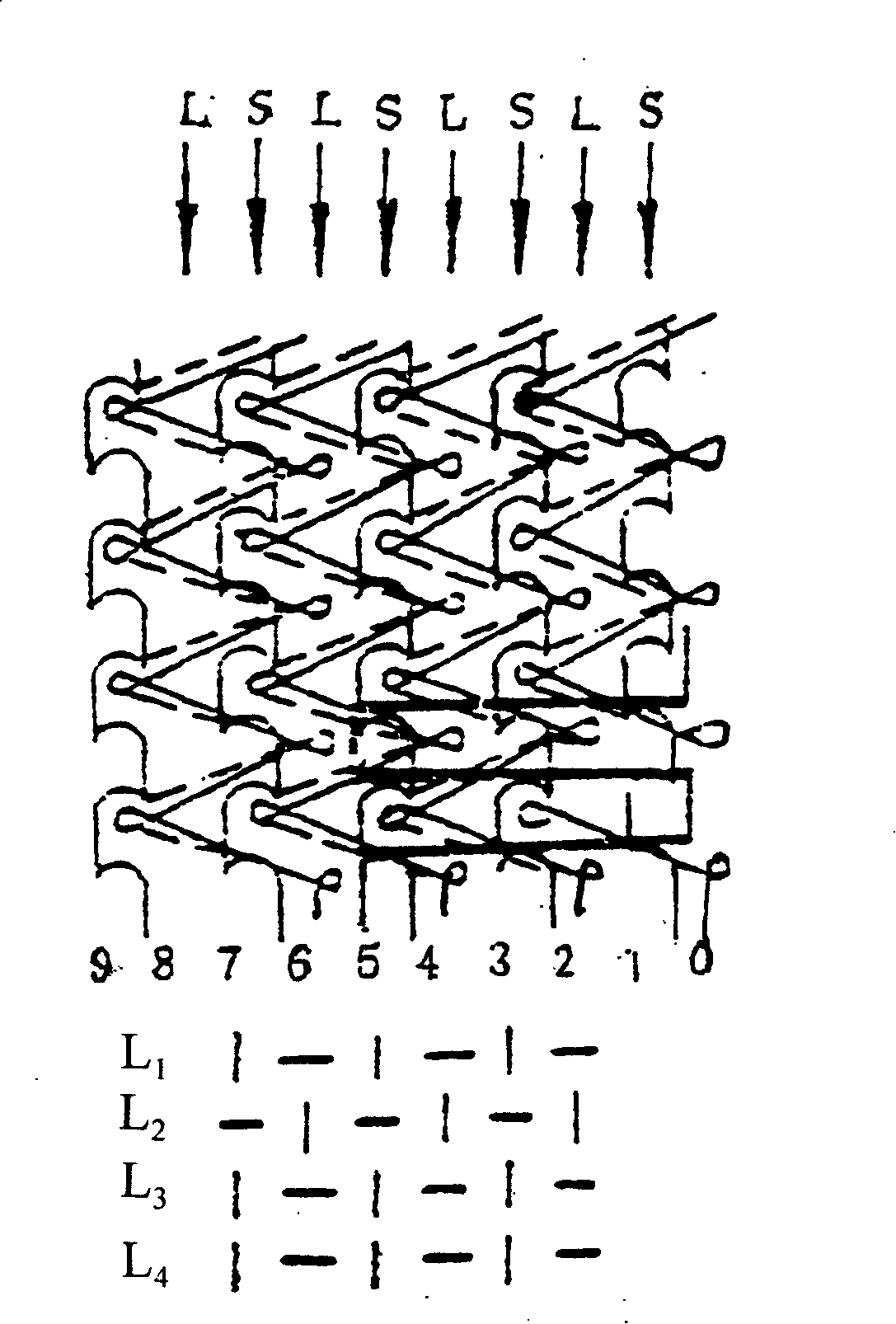

[0010] Embodiment 1: The production method of the present invention is to use polyester and nylon composite fibers as raw materials, and warp knitting technology is woven into a knitted fabric whose surface is densely and neatly arranged with loops, and countless ultrafine composite fibers that form loops are required. The junctions of all exist in the form of dead knots. The above-mentioned composite fiber type may be 150D / 72x16 (or 125D / 72x16, or other types). For the polyester and polyamide composite fibers used, the content ratio of polyester to polyamide can be 75:25 (or 80:20, or 70:30, or other content ratios). like figure 1 shown, cleaning wipes can be made using KS 4 FBZ terry warp knitting machine is knitted with 4 bars, and its division of labor is the rear comb L 1 For the front loop, use 3-2 / 6-6 / / ; L 2 For long-distance weft insertion, it is 5-5 / 0-0 / / ; L 3 For braiding, generally open 0-1 / 1-0 / / ; front comb L 4 Form back loops, 1-0 / 3-4 / / . The yarn alignment ...

Embodiment 2

[0011]Embodiment 2: The production method of the present invention is to use polyester and nylon composite fibers as raw materials, and warp knitting technology is woven into a knitted fabric whose surface is densely and neatly arranged with loops, and the countless ultrafine composite fibers that form loops are to be formed. The junctions of all exist in the form of dead knots. The above-mentioned composite fiber type is 125D / 72×16. For the polyester and nylon composite fibers used, the content ratio of polyester and nylon (can) is 70:30. like figure 1 shown, cleaning wipes can be made using KS 4 FBZ terry warp knitting machine is made of 4 combs. Next, the knitted fabric is cut and sewn after pre-treatment, degreasing process, fiber opening and stripping process, dyeing process, drying process and ironing process. Various specifications and shapes of cleaning wipes. In the pretreatment and degreasing process, the process conditions are that at room temperature, the knitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com