Foam dust-fall explosion prevention device

An anti-explosion device, foam technology, applied in the direction of dust prevention, fire prevention, chemical instruments and methods, etc., can solve the problems of increasing water consumption, wasting water sources, limited water mist contact surface, etc., to achieve large dust reduction contact surface, dust reduction and adsorption Strong performance and convenient daily operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

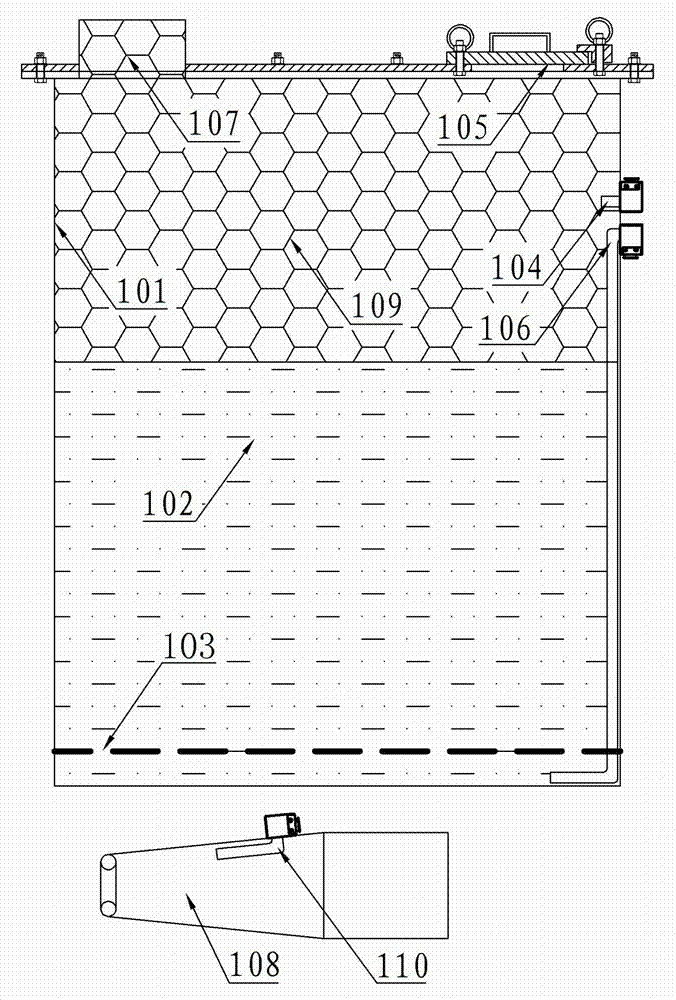

[0047] The foam 109 produced by the foam dust reduction and explosion-proof device can be sprayed to the dust generation place through the gun head 108 for dust reduction. The good adsorption of the foam 109 will be divided into adsorption and fixation, and at the same time, it will form a dust hard shell after drying to fix the dust.

Embodiment approach 2

[0049] The foam 109 produced by the foam dust suppression and explosion-proof device can wrap the dust-generating place through the gun head 108 for dust reduction. The huge contact surface of the foam 109 layer will wrap the dust-generating place, preventing the dust from spreading and eliminating the dust at the source.

Embodiment approach 3

[0051] The foam 109 produced by the foam dust reduction and explosion-proof device can carry out regional foam 109 filling anti-fire, foam 109 explosion-proof and regional foam 109 isolation, foam 109 has extremely strong fire extinguishing performance, and the foam 109 filled area can effectively prevent the disaster from spreading at the same time, Especially for gas explosion and coal dust explosion foam 109 filled area can effectively reduce or eliminate disasters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com