Inserting pile-connecting end plate fastener and prefab

A plug-in, pile-end technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of complex manufacturing molds and processes, slow speed of docking piles, high processing costs, etc., and achieves high work efficiency and accurate distribution , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

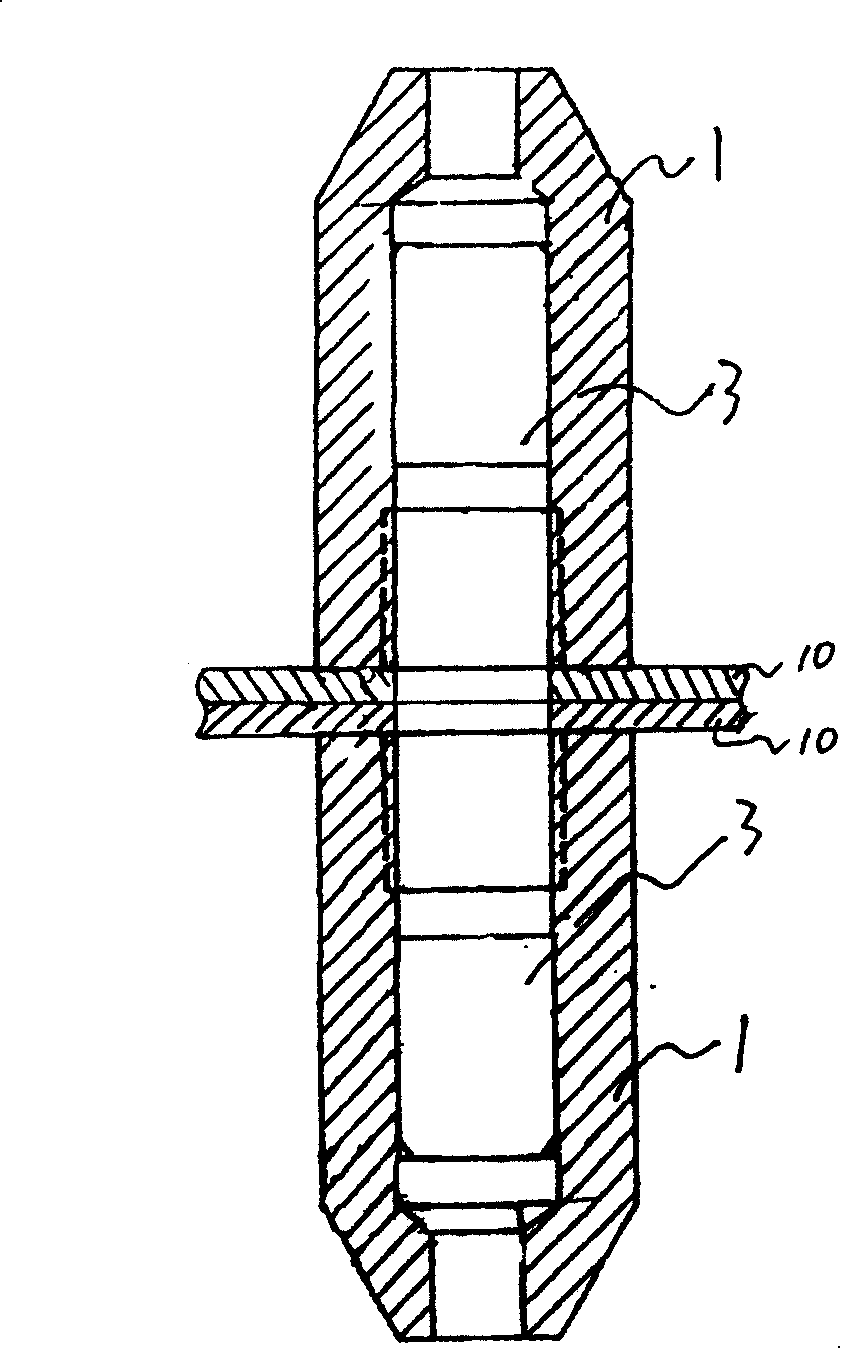

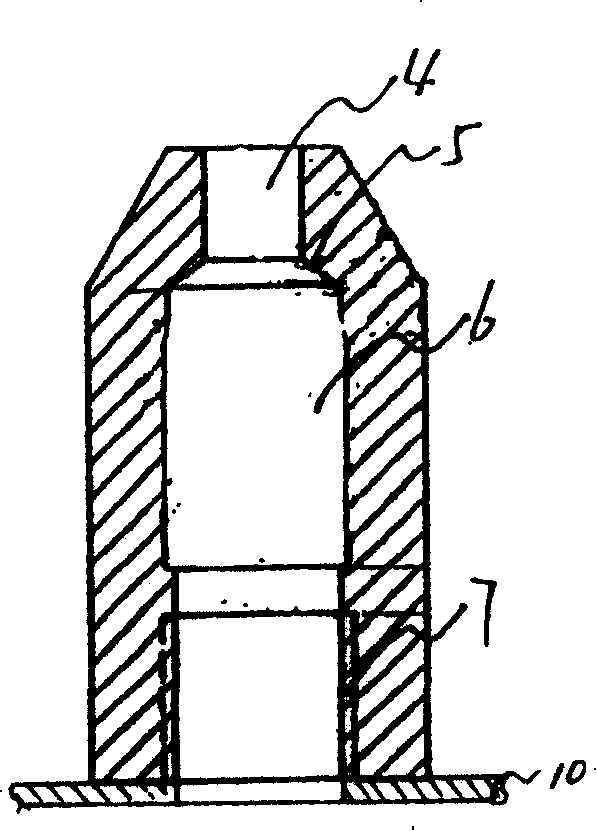

[0015] Embodiment 1: with reference to attached Figure 1~3 . Two or more plug-in nuts 1 are fixed on the end plate 10 of the plug-in type pile end plate buckle. in the cavity 6 and firmly connected with its cavity, see attached figure 1 . Plug nut 1 adopts metal (as steel, stainless steel, alloy steel etc.) or non-metallic material (as plastics, synthetic plastics, pottery etc.) to make by existing casting or injection molding or pottery firing or machining technology. The inner side of the cap opening of the plug-in nut 1 is a strong wire buckle 7, and the center of the bottom of the cap is provided with a steel bar hole 4. The periphery of the steel bar hole is a steel bar heading card platform 5, and the cavity 6 is between the card platform and the strong wire button. Connect the strong drawing wire buckle 7 of the inboard of nut 1 cap mouth and play the effect of strong drawing steel bar, see attached figure 2 . The double-ended connector body 1 is made of metal (s...

Embodiment 2

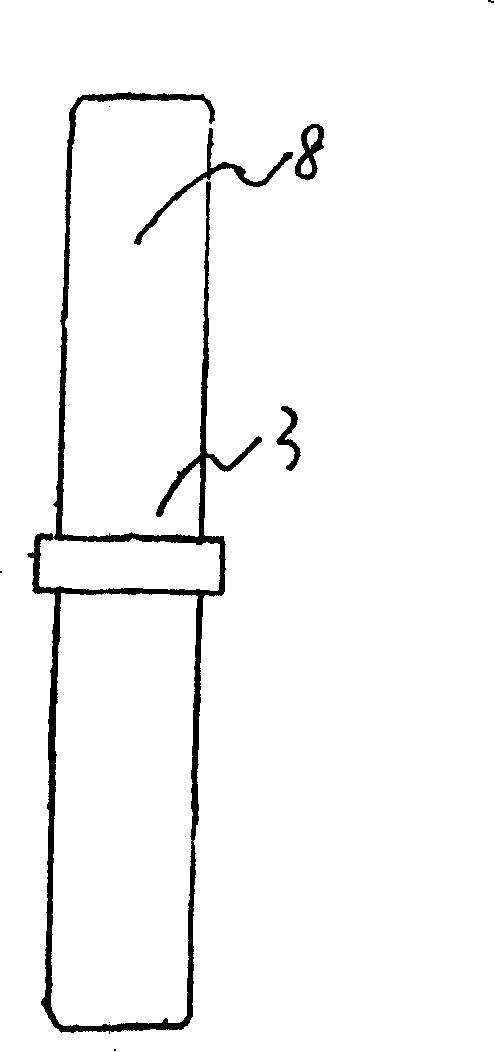

[0016] Embodiment 2: with reference to attached Figure 4 . On the basis of Example 1, the prefabricated parts (pipe piles----round tubular, square pipe piles, etc.) composed of plug-in pile end plate buckles, the prefabricated parts have built-in steel cages, and the two ends of the prefabricated parts The upsetting heads 9 at both ends of several longitudinal steel bars in the reinforcement cage are respectively clamped with the steel bar upsetting card table 5 in the plug-in nut 1 on the end plate, and the double-ended plug-in body 3 is used for the butt joint between prefabricated parts and prefabricated parts (When the double-ended plug-in body 3 is docked with the pipe pile, the plug-in body 8 in the double-ended plug-in body is inserted into the plug-in nut 1; when the pipe pile and the pipe pile are not docked, the double-ended plug-in body The connecting body 3 is separated from the inserting nut 1 and kept separately). Plug nut 1 and double-ended connector 3 are ma...

Embodiment 3

[0017] Embodiment 3: with reference to accompanying drawing 7. On the basis of Examples 1 and 2, the prefabricated part is composed of plug-in pile end plate buckle, the prefabricated part has a built-in reinforcement cage, and the two ends of several longitudinal steel bars in the reinforced cage at both ends of the prefabricated part 2 are upset 9 They are respectively stuck on the inserting nut 1 and the steel bar heading card table 5, and the double-ended inserting body 3 is used for the butt joint between the prefabricated parts and the prefabricated parts. The butt joint of the connector is sealed with resin, sulfur, cement and other corrosion-resistant materials to prevent it from rusting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com