Infrared purification apparatus of diesel engine exhaust gas and scouring method thereof

A technology for diesel engines and purification devices, which is applied to exhaust devices, engine components, machines/engines, etc., to achieve the effect of rapid thermal oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

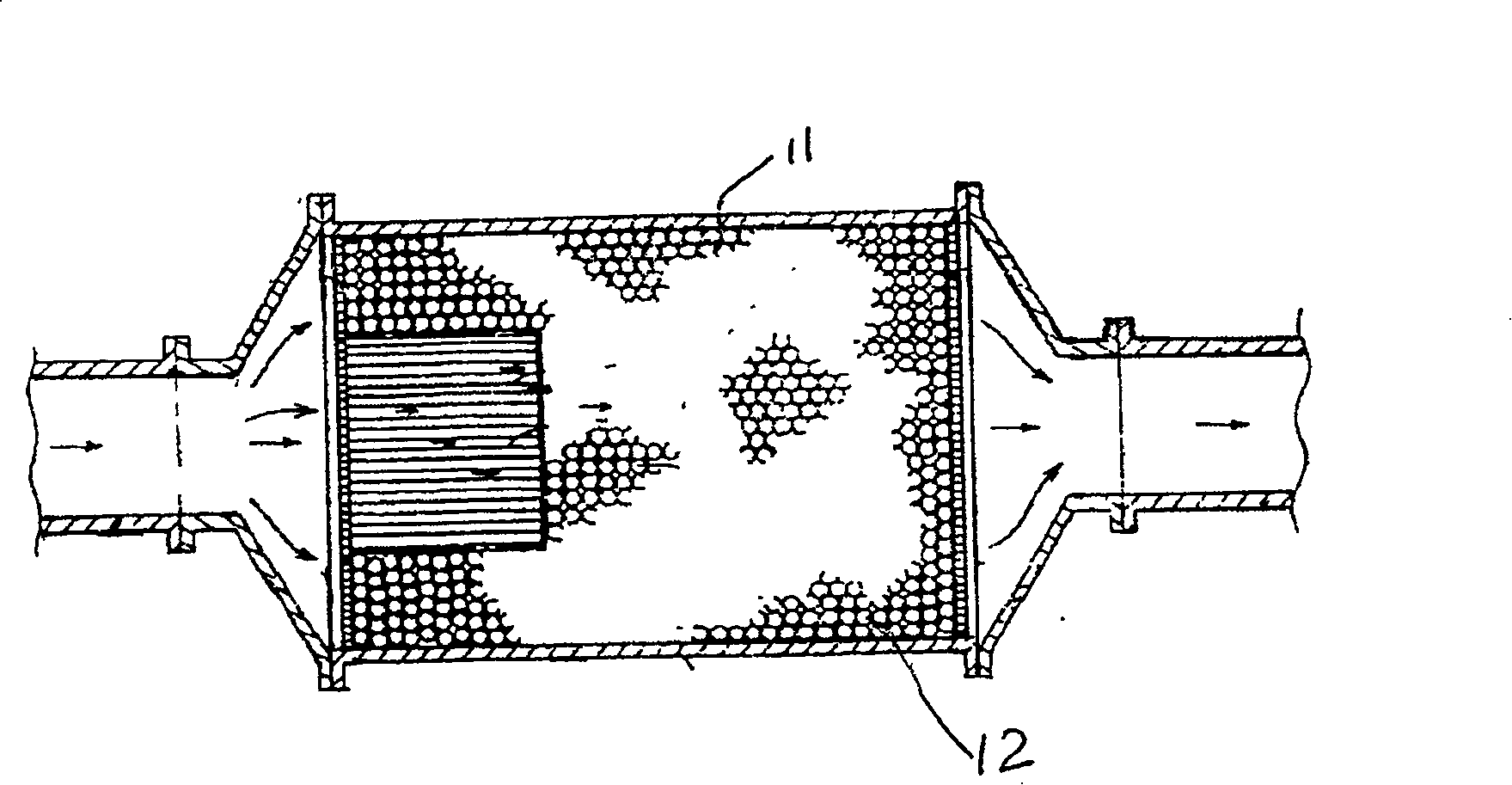

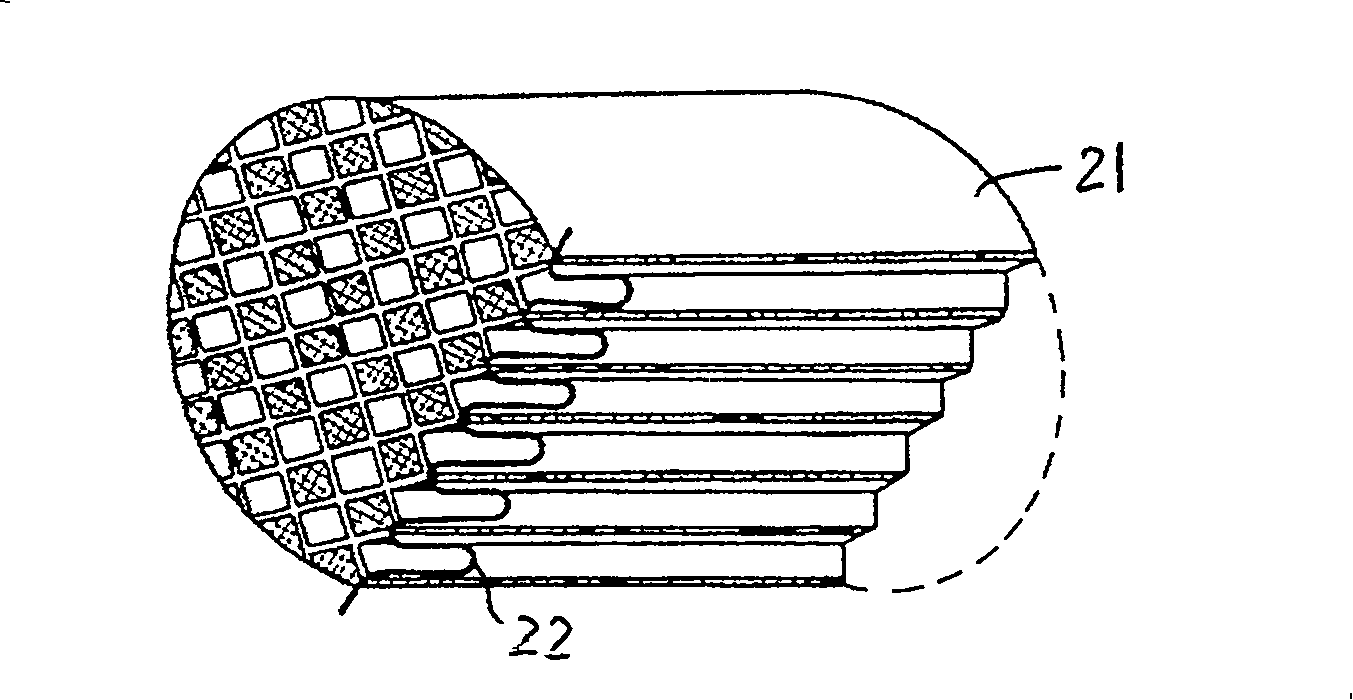

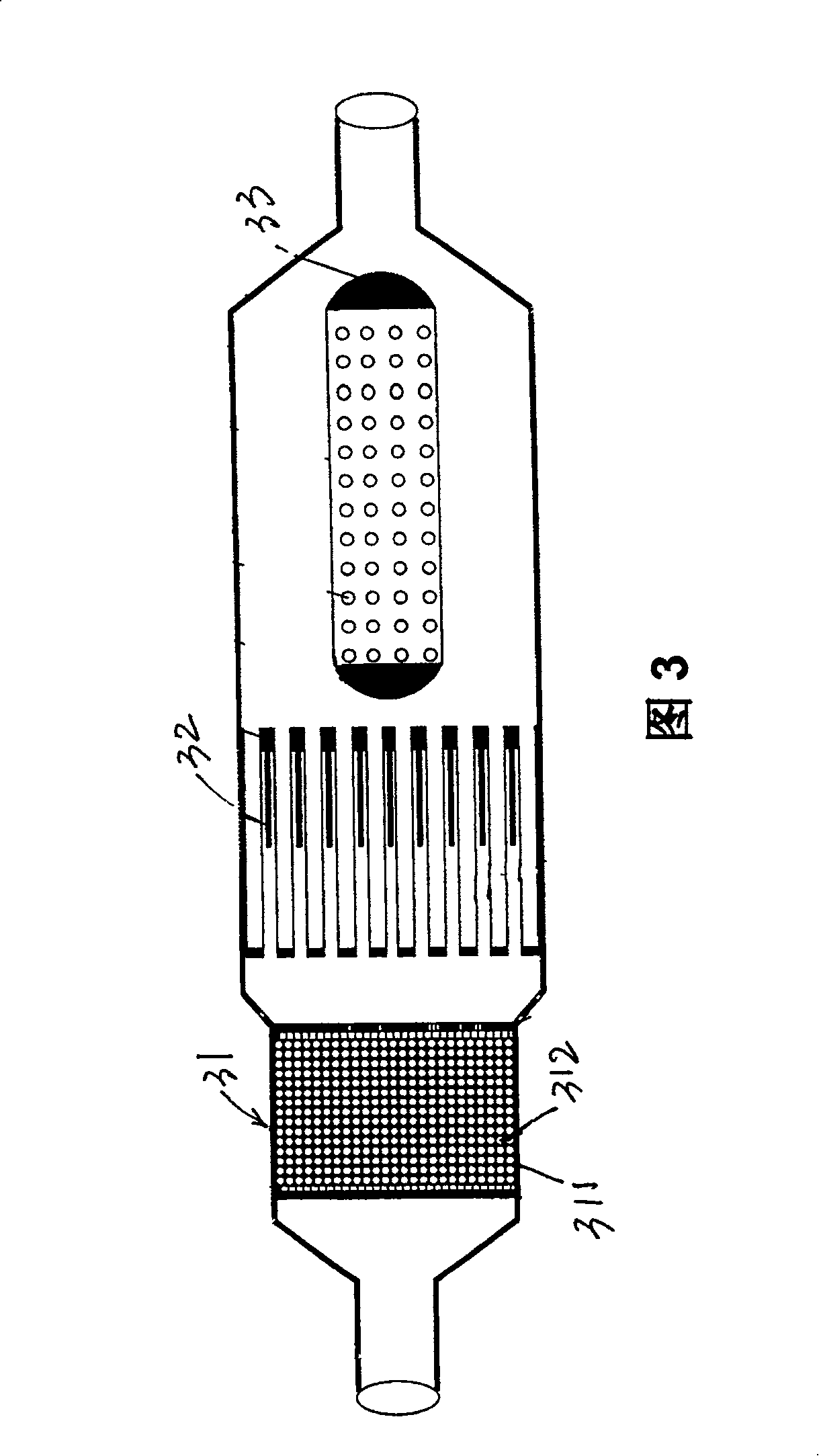

[0042] See Figure 4. The diesel engine exhaust infrared purification device of the present invention is made of a honeycomb heating purifier 3, and this honeycomb heating purifier comprises an intake pipe end cover 31, an exhaust pipe end cover 32 and is connected to the intake pipe end cover, The shell formed by the annular cylinder 33 between the end caps of the exhaust pipe, the two sides of the cylinder are respectively provided with a filter screen 34 and a porous plate 35 sequentially from the outside to the inside, and a cavity is formed in the middle, and in the cavity (between the two porous plates ) is densely filled with infrared spheres 36; a buffer net 37 behind the perforated plate at the intake end side, and two layers of catching filter screens 38 arranged at intervals in the cylinder. The structure traps particles in the direction of axial flow.

[0043] See Figure 5. The buffer net 37 of the present invention has a diameter smaller than that of the perforat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com