Method for controlling growth density of carbon nanometer tube

A carbon nanotube and density technology, which is applied in the field of controlling the growth density of carbon nanotubes, can solve the problems of uneven distribution density of carbon nanotubes and difficulty in controlling the distribution density of catalyst particles, and achieve a controllable and uniform distribution density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

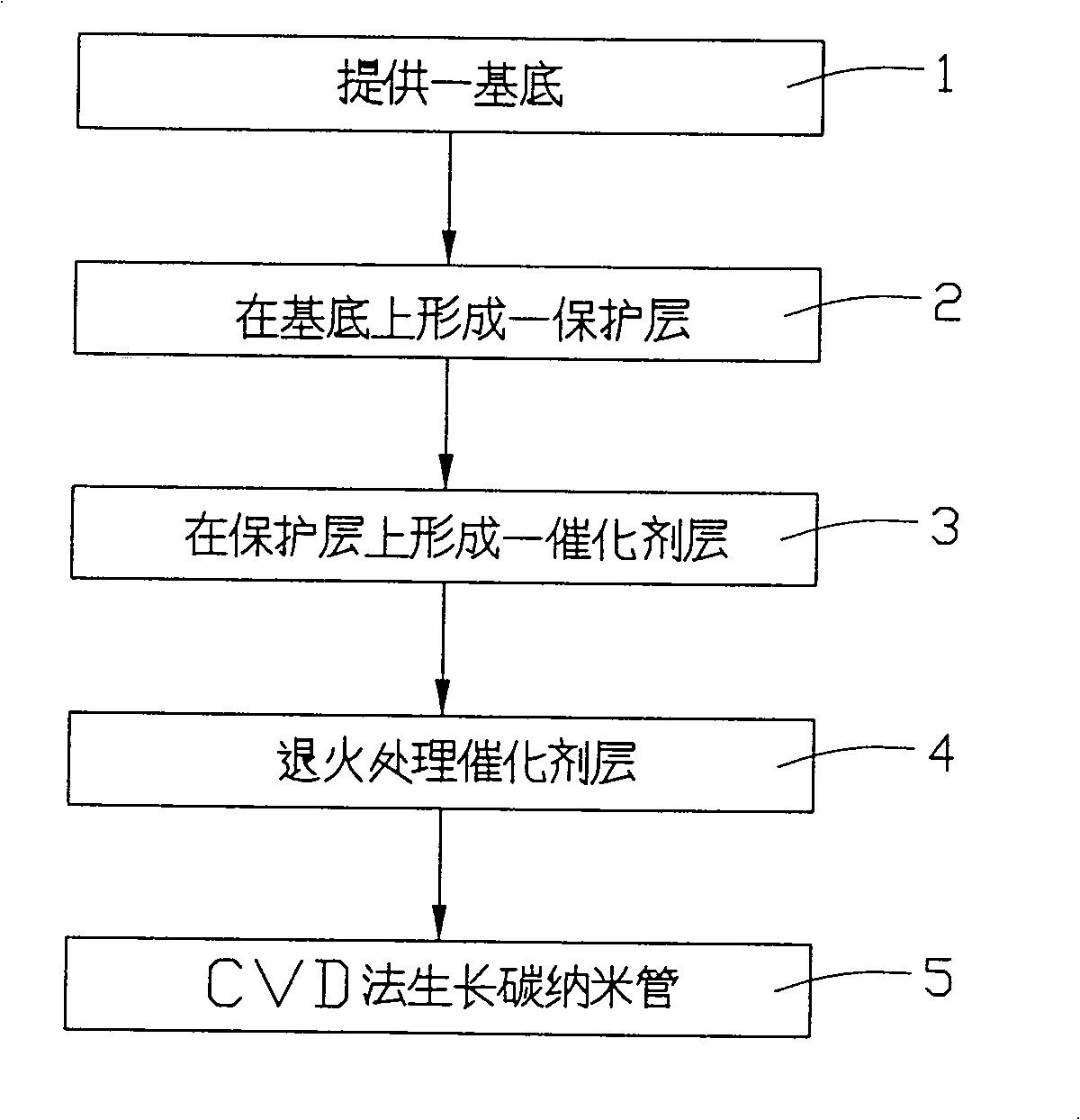

[0014] See figure 1 , is a flowchart of the method for controlling the growth density of carbon nanotubes in the present invention. The inventive method comprises the following steps:

[0015] Step 1, providing a substrate. The substrate material includes porous silicon, quartz or metal, etc., and it only needs to be able to withstand the high temperature conditions required by the chemical vapor deposition method for growing carbon nanotubes. This substrate has a flat surface that serves as a support base for subsequent steps.

[0016] Step 2, forming a protective layer on the surface of the substrate. This step is to form a protective layer with a certain thickness on the surface of the substrate to avoid direct contact between the catalyst layer and the substrate surface, thereby preventing the catalyst from chemically reacting with the substrate when the catalyst is annealed and reduced, so that the distribution density of nanoscale catalyst particles formed after annea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com