Tracking method of on-line measuring roundness error and machine tool main axle error

A roundness error, machine tool spindle technology, applied in the direction of grinding machine tool components, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problem that the center and the rotation center do not coincide, such as grinding crankshaft connecting rod neck and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] A preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

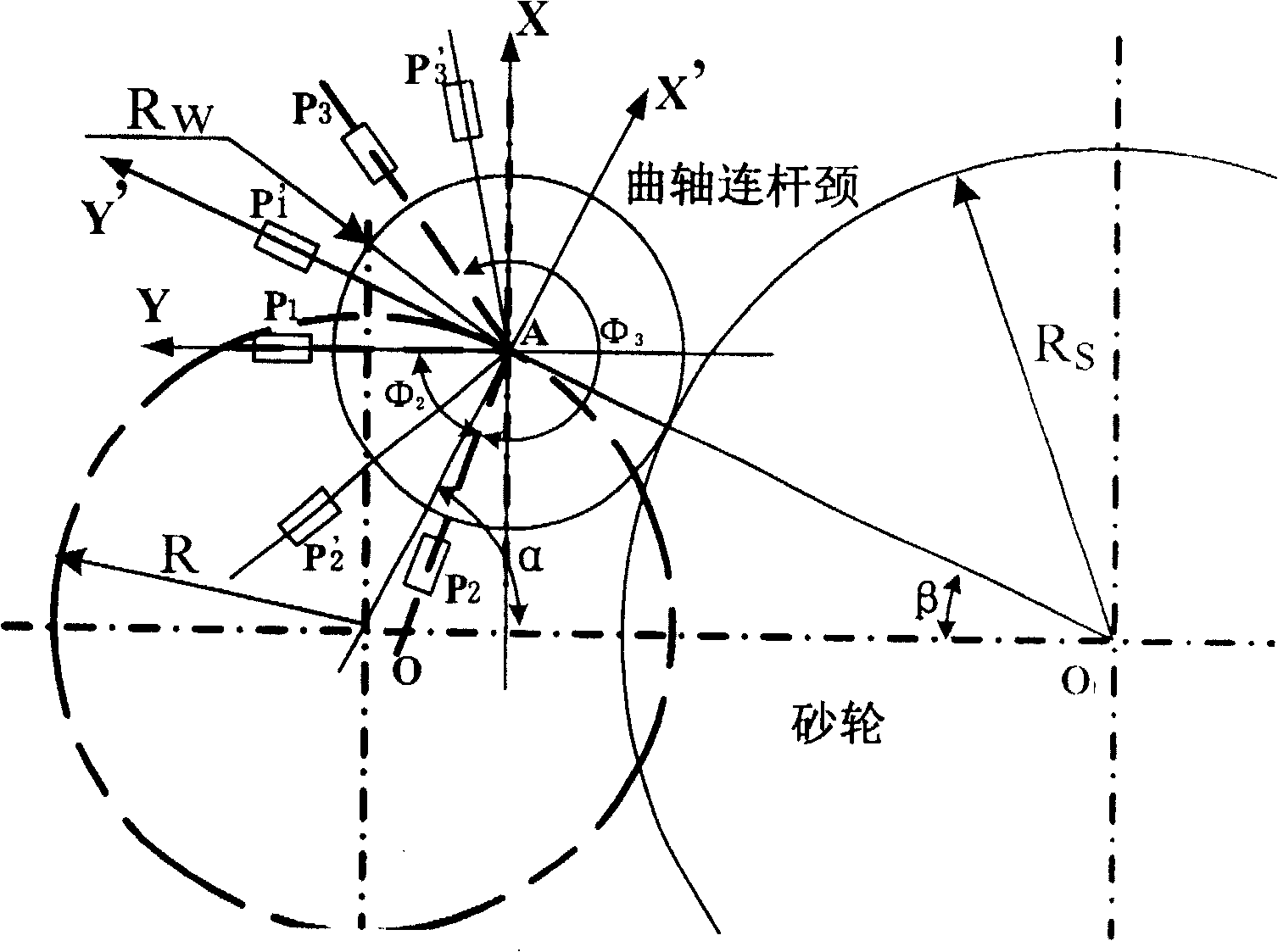

[0058] The tracking method for on-line measurement of roundness error and machine tool spindle error is based on the time-domain signal collected by the three displacement sensors in the tracking-type roundness and linear online measurement mechanism in the tracking measurement, which is transformed into the frequency domain for analysis. The roundness error and systematic error of the eccentrically rotating workpiece are separated.

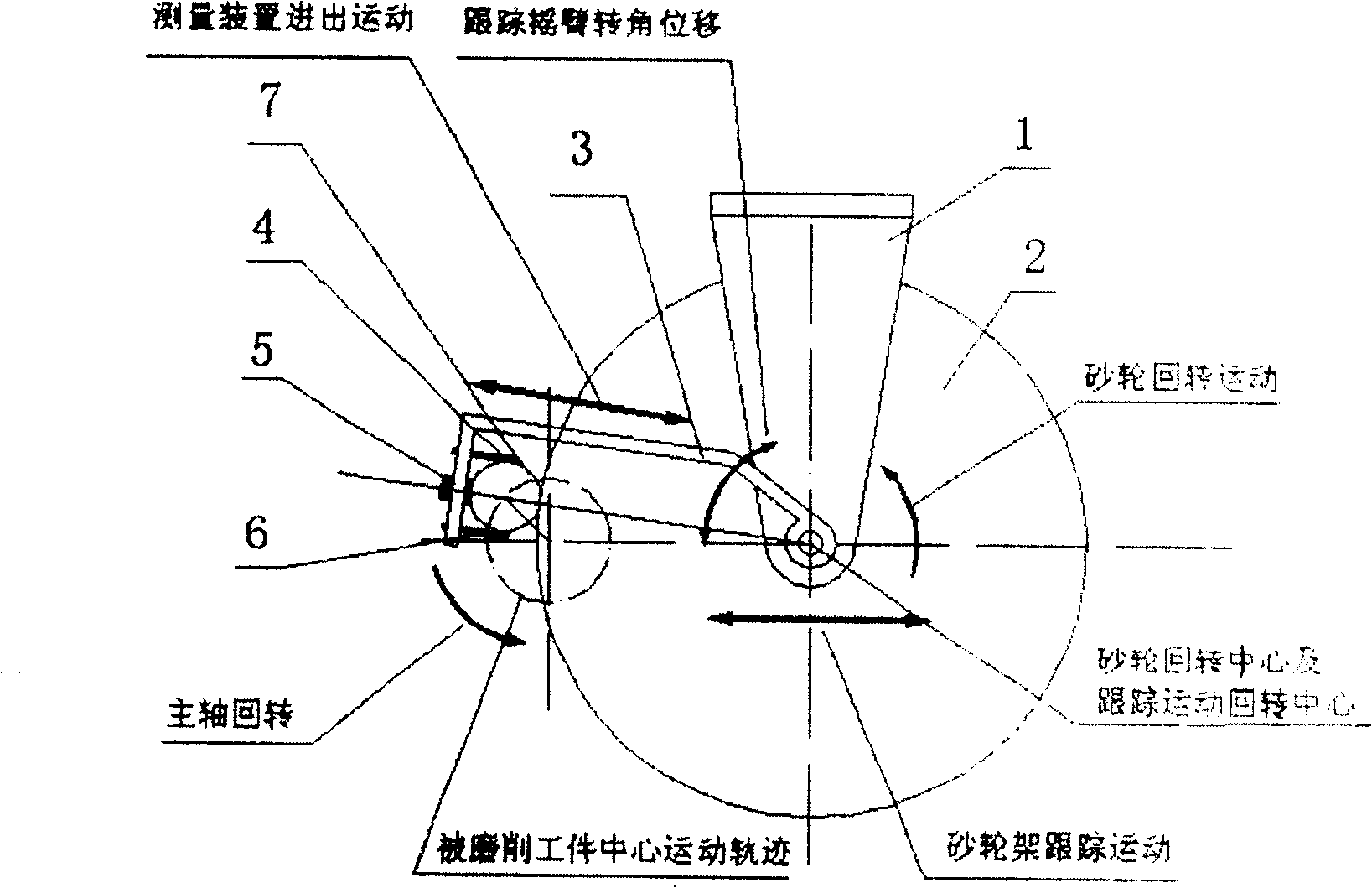

[0059] see figure 1 The above-mentioned tracking type roundness and diameter online measuring mechanism includes a measuring mechanism base 1 fixedly connected with the grinding wheel frame, and a tracking rocker 3 that swings coaxially with the grinding wheel 2 is installed on the measuring mechanism base 1, and the tracking rocker The outer end of the arm 3 is equipped with three displacement sensors 4, 5, 6 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com