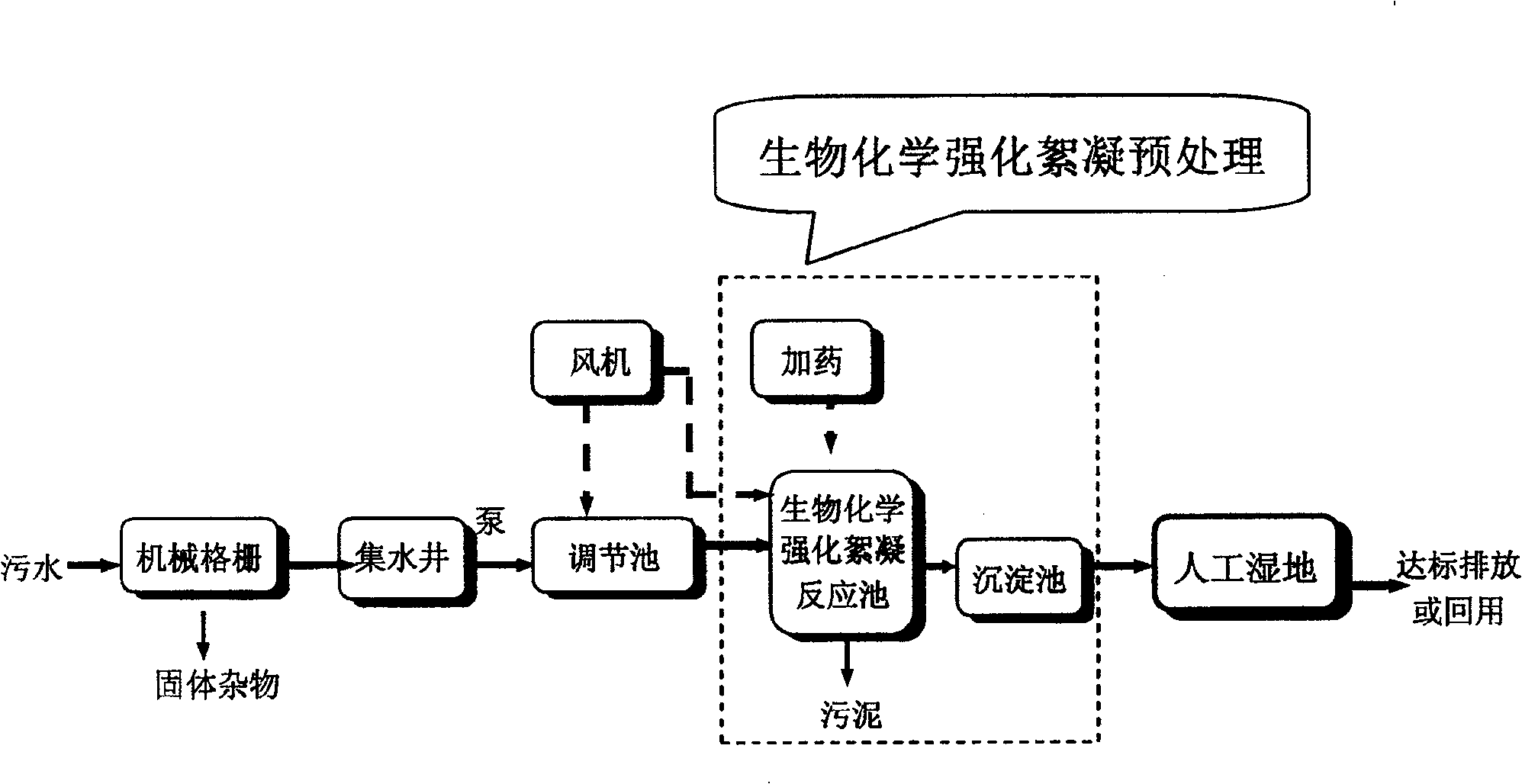

Combined process of reinforced biochemical flocculation and artificial wet land treatment of sewage

A constructed wetland and biochemical technology, applied in biological water/sewage treatment, flocculation/sedimentation water/sewage treatment, sustainable biological treatment, etc., can solve the problem of large area, easy blockage, and restrictions on the promotion of constructed wetland sewage treatment technology and other issues, to achieve the effect of reducing the occupied area, reducing the investment cost and increasing the surface hydraulic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Sewage treatment project in a forest tourism park:

[0019] Treated water volume: 3000m 3 / d domestic sewage; influent and effluent water quality is as follows:

[0020] serial number

project

flooded

out of water

1

COD Cr (mg / l)

≤350

≤50

2

BOD 5 (mg / l)

≤150

≤20

3

SS(mg / l)

≤200

≤20

[0021] 4

NH 3 -N (mg / l)

≤30

≤8

5

TP (mg / l)

≤5

≤0.4

[0022] The sewage first enters the collection well through the mechanical grille to remove larger solid impurities. The sewage from the collection well is pumped up to the adjustment tank to homogenize the water quality and quantity, and then enters the reaction tank, where the coagulant basic aluminum chloride is added (PAC) 50mg / L and flocculant polyacrylamide PAM0.5mg / L, after fully reacting, enter the sedimentation tank for mud-water separation, and the effluent from ...

Embodiment 2

[0025] A sewage treatment project in a residential area:

[0026] Treated water volume: 630m 3 / d domestic sewage; influent and effluent water quality is as follows:

[0027] serial number

project

flooded

out of water

1

COD Cr (mg / l)

≤350

≤60

2

BOD 5 (mg / l)

≤150

≤20

3

SS(mg / l)

≤200

≤20

4

NH 3 -N (mg / l)

≤30

≤8

5

TP (mg / l)

≤5

≤1

[0028] The sewage first enters the water collection well through the mechanical grille to remove large solid impurities. The sewage from the water collection well is pumped to the regulating tank to homogenize the water quality and quantity, and then enters the reaction tank, where the coagulant ferric chloride (FeCl 3 )70mg / L, after fully reacting, it enters the sedimentation tank for mud-water separation, and the effluent from the sedimentation tank enters the constructed wetland for further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com