Composite panel and method for manufacturing the same

A production method and technology of composite panels, which are applied in the fields of panels and furniture for architectural decoration, can solve the problems of inconsistent production methods of composite panels, lack of ornamental functionality, unstable product quality, etc., and achieve moisture-proof and anti-permeability performance. Reliable, easy to mass manufacture, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

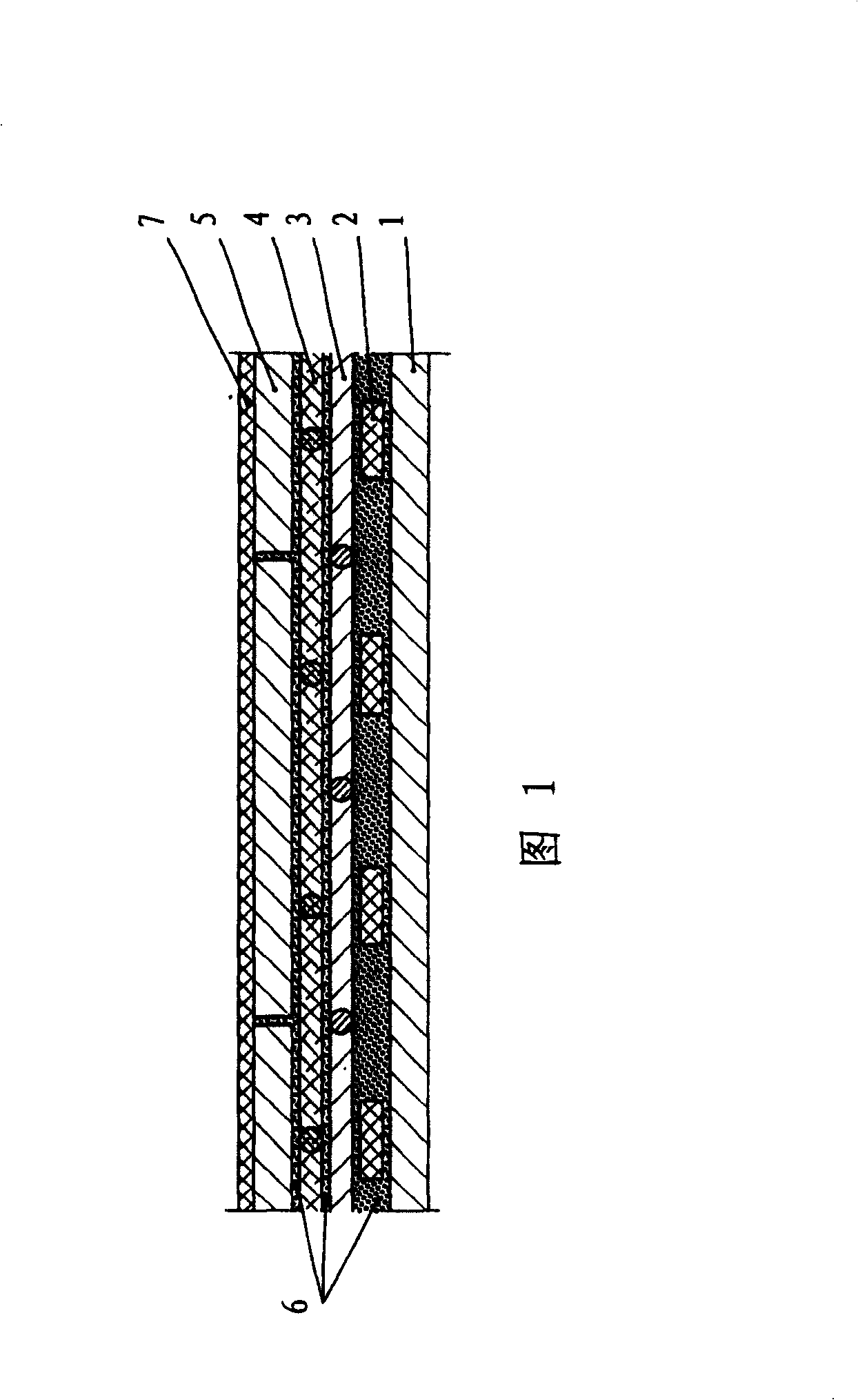

[0018] As can be seen from Figure 1, the composite panel of the present invention includes a base plate 1; wherein on the surface of the base plate 1, a skeleton 2 or / and a metal mesh 3, a glass fiber mesh 4 and a panel 5 are arranged in sequence, and are bonded and solidified with an adhesive 6 Forming; and the panel 5 is made of several pieces of different sizes, shapes, and materials or / and the same sheets are glued together; the protective layer 7 is coated on the surface of the panel 5 .

[0019] The base plate 1 is a calcium silicate board, a magnesium resistant board, a magnesium ore board or a plastic board or a ceramic board or a metal board, and this type of board has high strength and corrosion resistance. Skeleton 2 is a hard non-metal strip or metal strip, such as various metal wires or thin strips such as wooden strips, bamboo strips, and iron wires, which are generally placed along the length direction of the composite board; metal mesh 3 is a whole body slightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com