Pot possessing composite bottom and its processing technology

A technology of composite bottom pot and pot body, which is applied in the direction of special materials for cooking utensils, cooking utensils, household utensils, etc., to achieve the effects of uniform force, simple production process and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

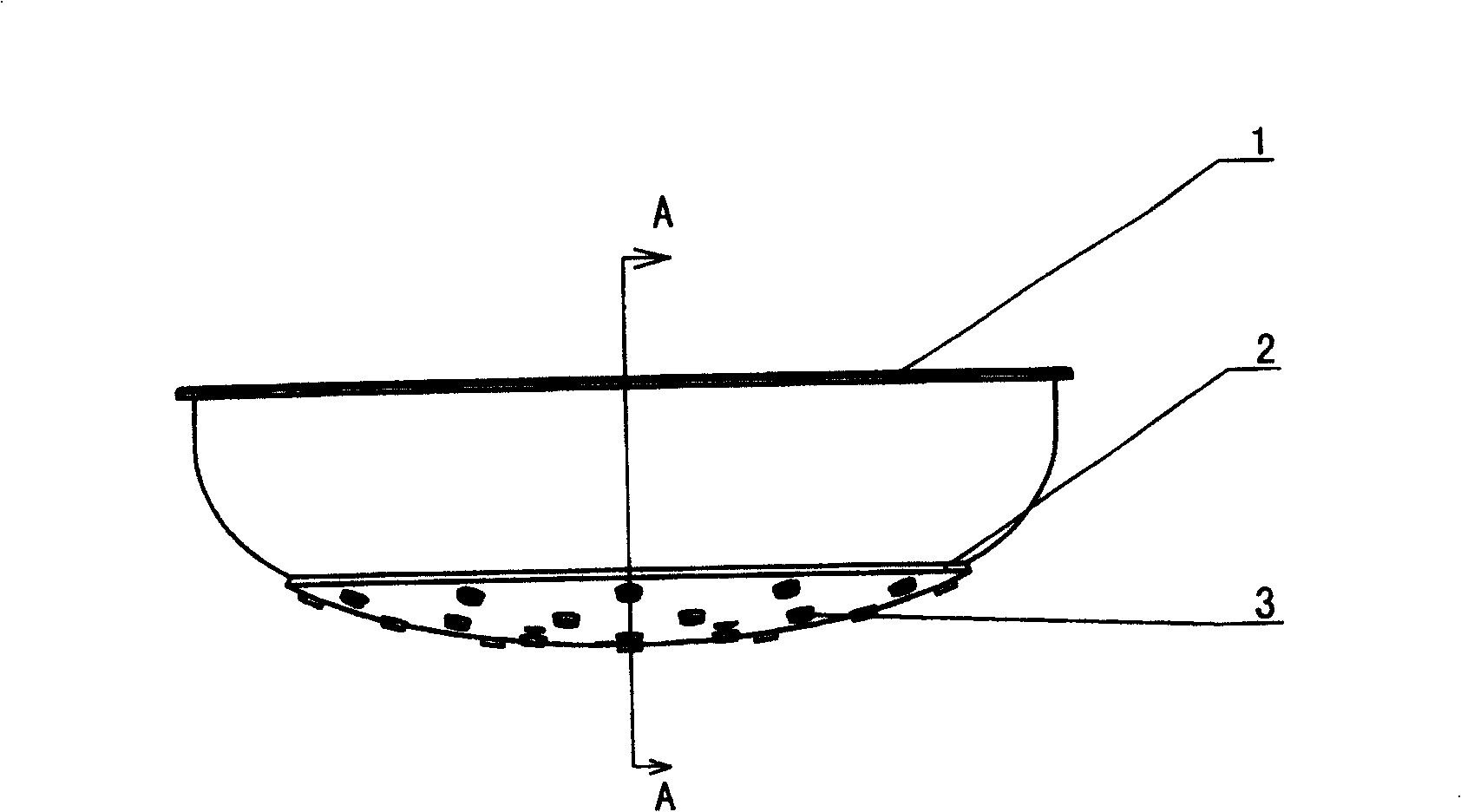

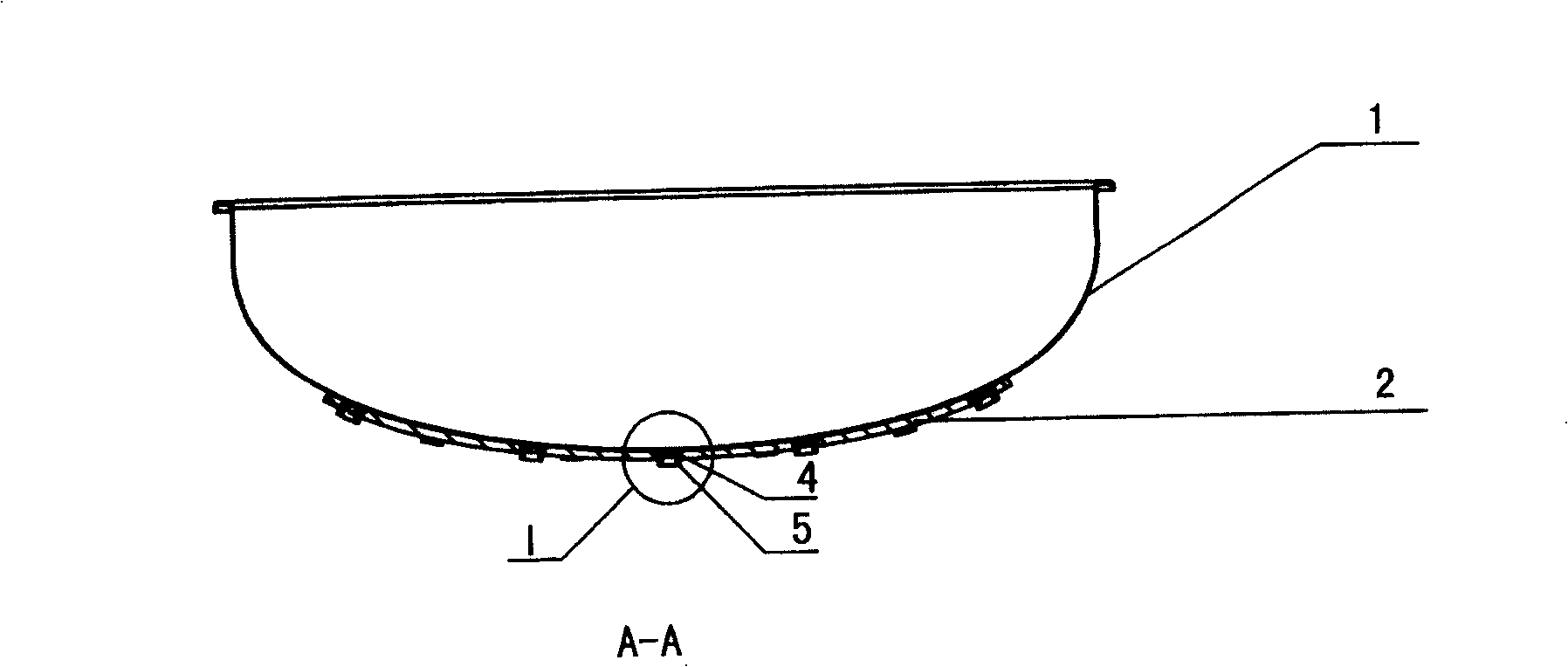

[0019] Attached below figure 1 -5 To further explain the present invention:

[0020] Such as Figure 1-2 As shown, the composite bottom pot mainly includes a pot body 1, an aluminum soaking plate 2, a through hole 3, a dot nail 4, and an aluminum riveting tube 5. The pot body 1, dot nail 4 is made of stainless steel, and the soaking plate 2, riveting The joint tube 5 is made of aluminum. The spot nails 4 can be designed as hollow or solid, and spot welded at even intervals on the outside of the bottom of the pot body 1. The soaking plate 2 is provided with through holes 3 corresponding to the spot nails 4, aluminum rivets The joint tube 5 is sleeved outside the point nail 4 in the through hole 3, and the lead flux and solder for brazing are coated between the outside of the bottom of the pot body 1 and the soaking plate 2.

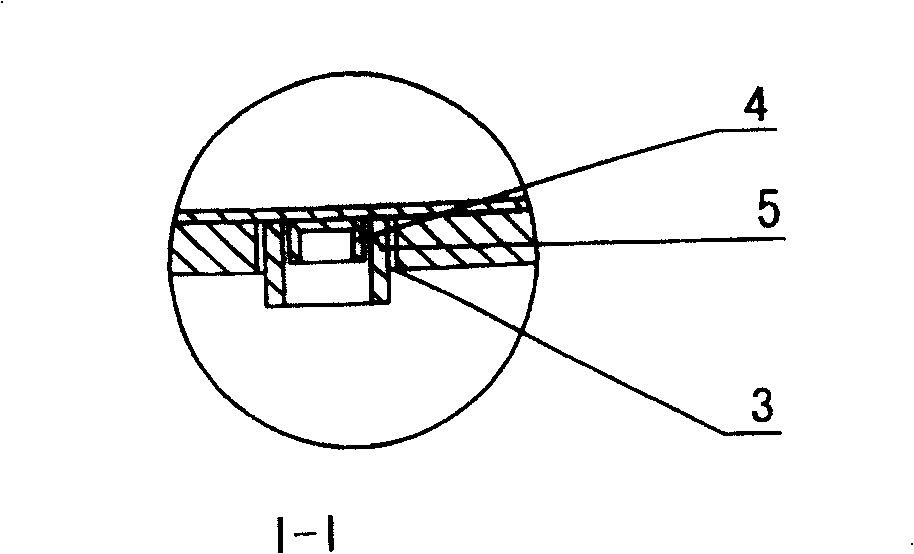

[0021] image 3 It is a partial enlarged schematic diagram before riveting; at this time, the aluminum riveting tube 5 is sleeved outside the point nail 4 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com