Fastener driving tool

A fastener and tool technology, which is applied in the field of internal combustion fastener propulsion tools, can solve problems such as ignition failure, equipment output fluctuation, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

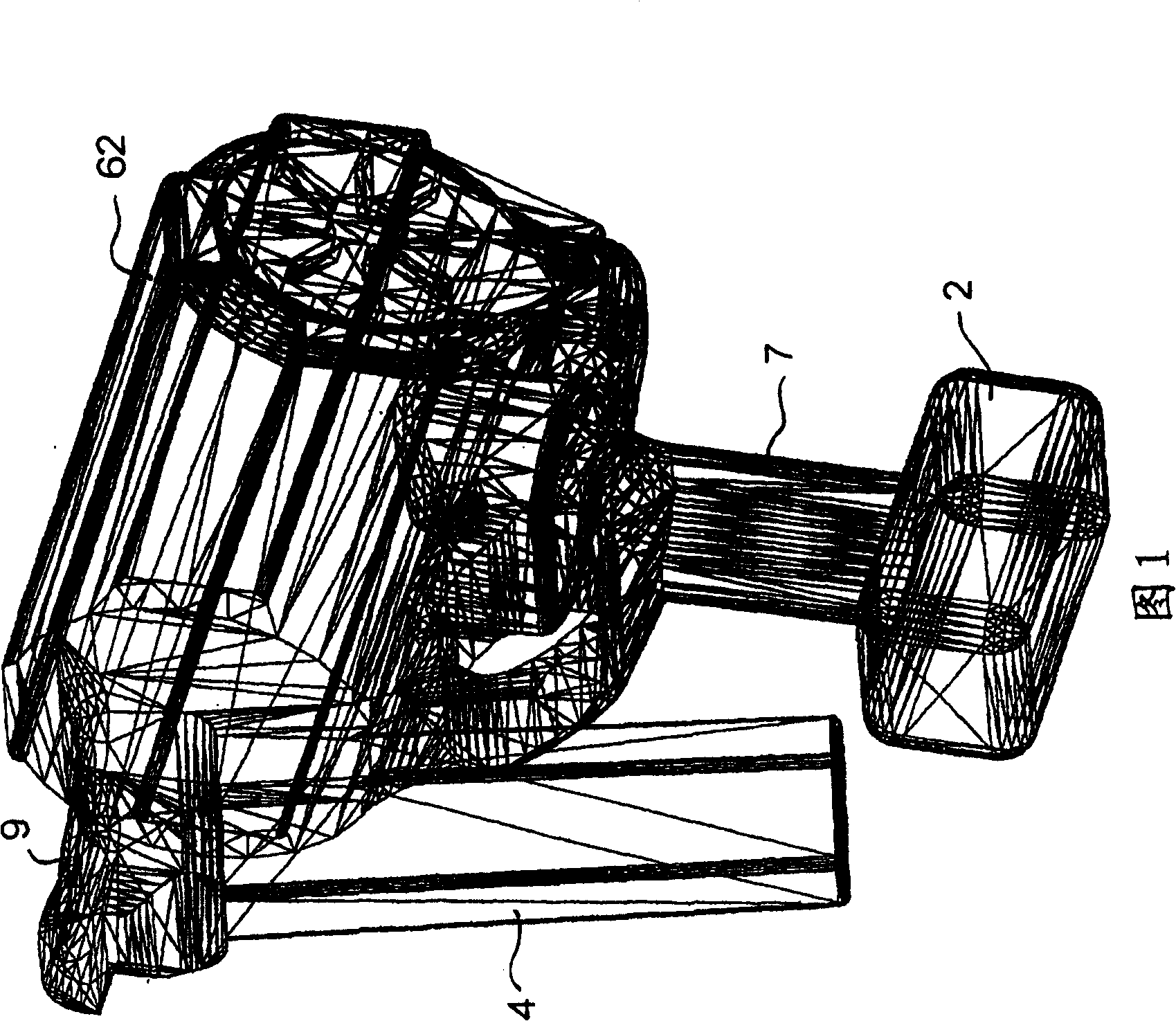

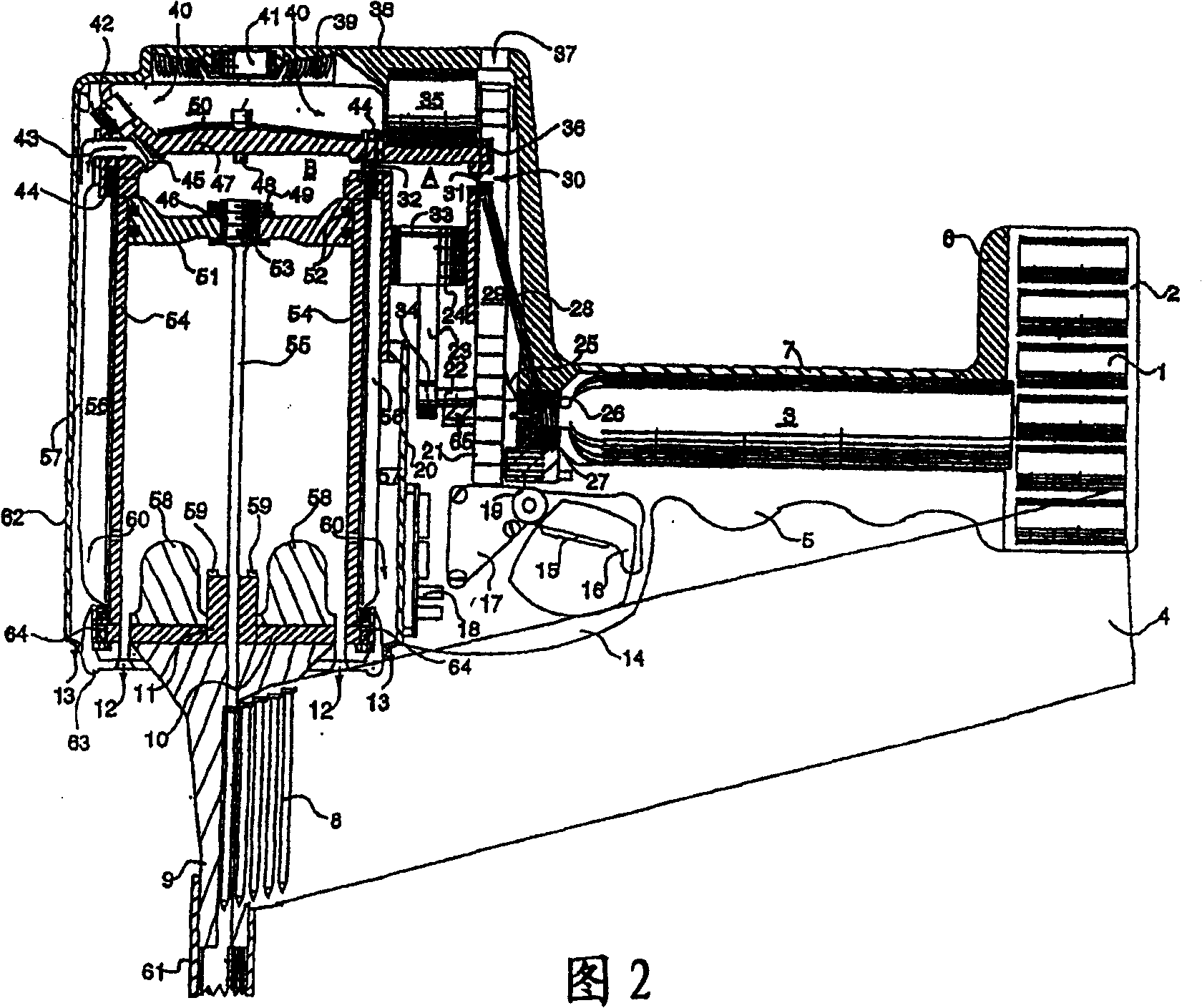

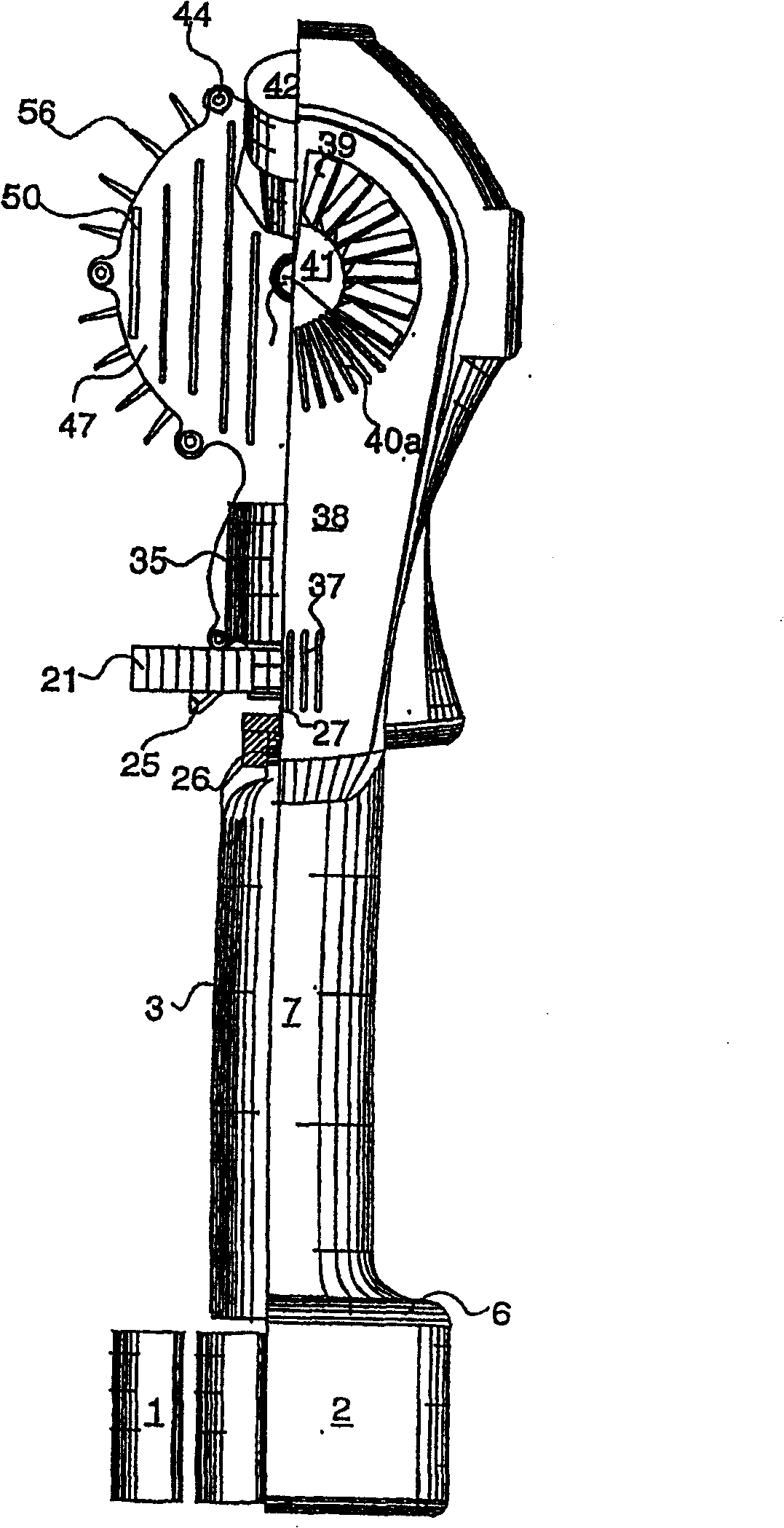

[0037] Figures 1 and 2 show a combustion driven nail gun (tool) for firing nail fasteners. The nail gun includes a preparatory cylinder A and a power boost cylinder B housed in a tool body housing 62 . A tool support handle 7 with a grip 5 extends from the housing 62 and houses a fuel cartridge (reservoir) 3 . A battery 1 housed in a detachable battery case 2 is attached to a support handle 7 . The nail fastener barrel (or nail box) 4 delivers the nail fasteners 8 to the tool nose (or barrel) 9 .

[0038] The operation of the combustion nail gun will now be described. The user holds the combustion driven nail gun by the tool support handle 7 and the gun handle 5 . The user's finger is placed on the firing trigger 16 . The main micro trigger 15 is actuated. An electronic central processing unit (CPU) 18 is notified that the tool is in operation. The CPU 18 is switched on to the circuit of the ready cylinder drive with circulating sensor wheel 21 and main power supply slip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com