Buffer type hydraulic weighing device

A weighing device and hydraulic technology, used in measuring devices, weighing devices using fluid balance, weighing, etc., can solve the problems of unreliable stability, large space occupation, complex structure, etc., and achieve wide practicability and reliability. Strong performance, compact structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

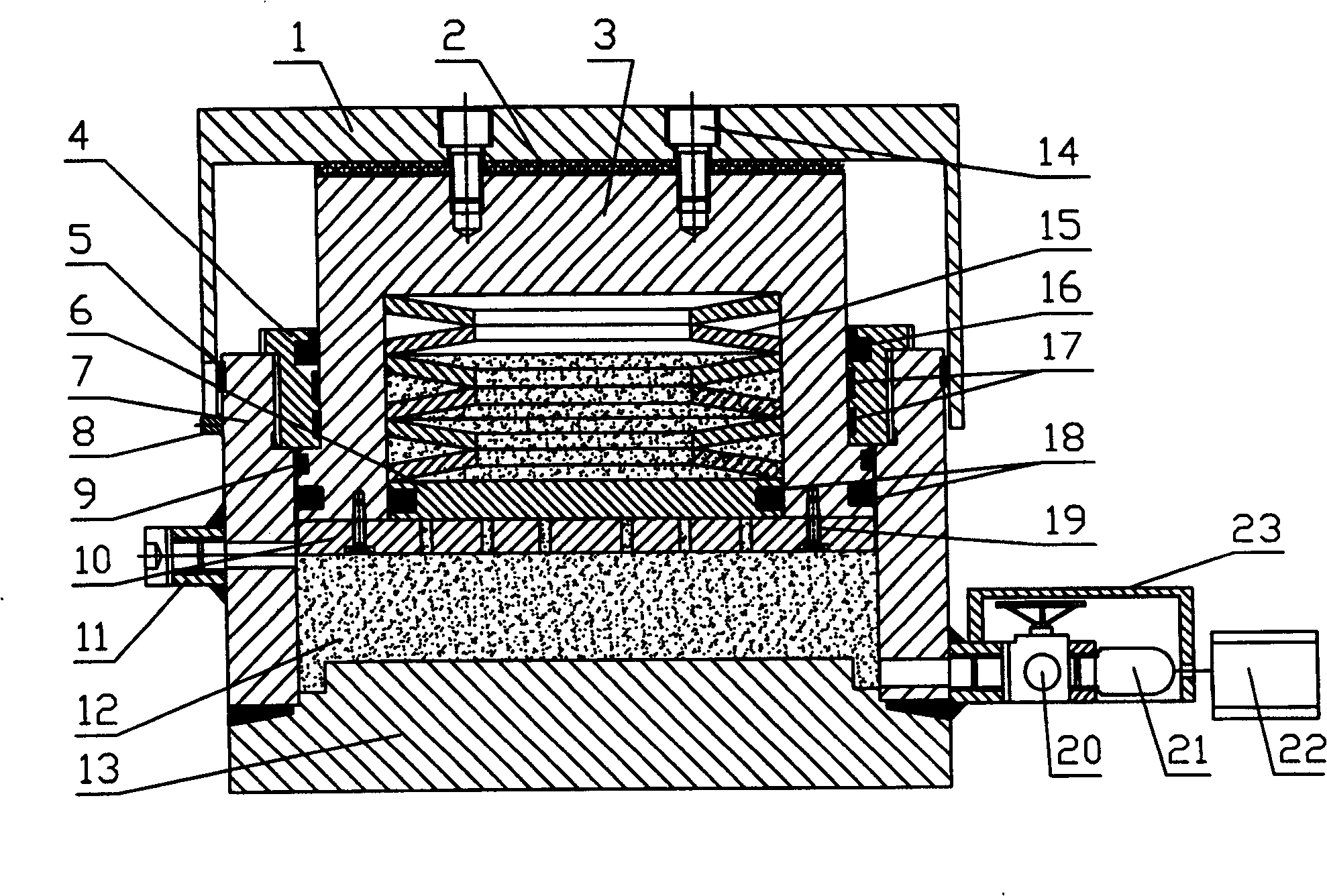

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0010] The buffer type hydraulic weighing device of the present invention is mainly composed of an oil cylinder cover 1, a piston rod 3, a guide sleeve 4, a disc spring baffle 6, a cylinder body 7, a damping baffle 10, an exhaust bolt 11, a cylinder bottom 13, a plate Formed spring 15, stop valve 20, pressure transmitter 21, data acquisition system 22. The piston rod 3 is located in the cylinder body 7 and can move up and down. The piston rod 3 is provided with a counterbore downward, and the disc spring 15 and the spring baffle 6 are arranged in the hole, and the bottom end of the piston rod 3 is provided with a damping baffle. 10. There are several small holes on the damping baffle 10, and the damping baffle 10 is connected with the piston rod 3 through the screw 19, so that the spring baffle 6 and the disk spring 15 are closed in the counterbore cavity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com