Glass substrate for magnetic disk and magnetic disk

A technology for glass substrates and magnetic disks, applied in magnetic recording, magnetic recording layers, base layers of recording layers, etc., can solve problems such as difficult disk speeding, reduced suspension stability of magnetic heads, and reduced linear speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0145] Hereinafter, it demonstrates concretely by giving an Example and a comparative example. Furthermore, the present invention is not limited to the configurations of these examples.

Embodiment 1

[0146] [Example 1 (Example of Glass Substrate for Magnetic Disk)]

[0147] The glass substrate for magnetic discs of the present Example described below was produced through the following steps (1) to (8).

[0148] (1) Rough grinding process

[0149] (2) Shape processing process

[0150] (3) Fine grinding process

[0151] (4) End mirror surface processing process

[0152] (5) The first grinding process

[0153] (6) Second grinding process

[0154] (7) Chemical strengthening process

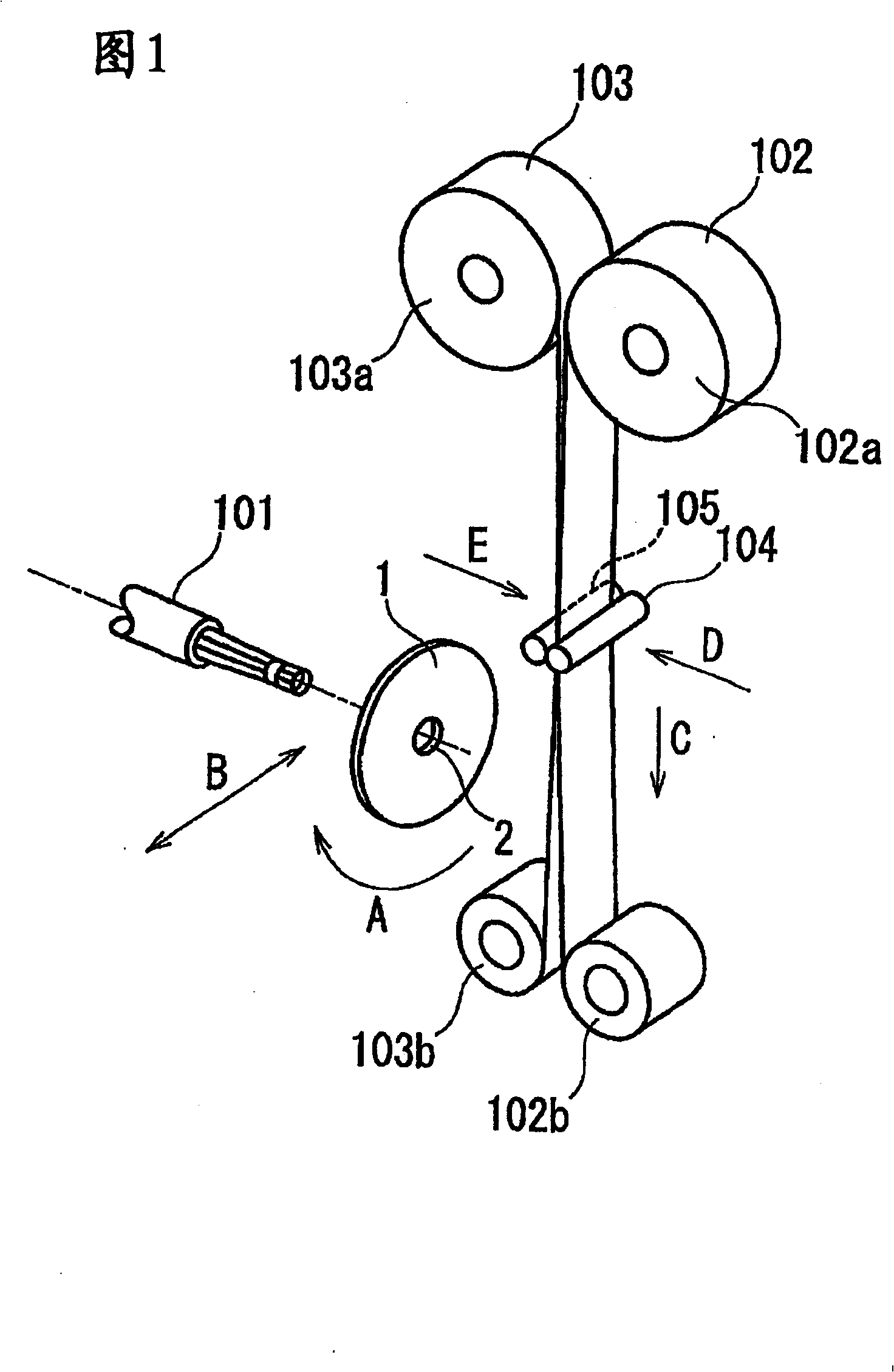

[0155] (8) Texture processing

[0156] First, a disk-shaped glass base material made of amorphous aluminosilicate glass is prepared. This aluminosilicate glass contains lithium. The composition of the aluminosilicate glass is to contain 63.6% by weight of SiO 2 , 14.2 wt% Al 2 o 3 , 10.4 wt% Na 2 O, 5.4 wt% Li 2 O, 6.0 wt% ZrO 2 , 0.4 wt% Sb 2 o 3 .

[0157] (1) Rough grinding process

[0158] A plate glass having a thickness of 0.6 mm formed from molten aluminosilicate glass was...

Embodiment 2

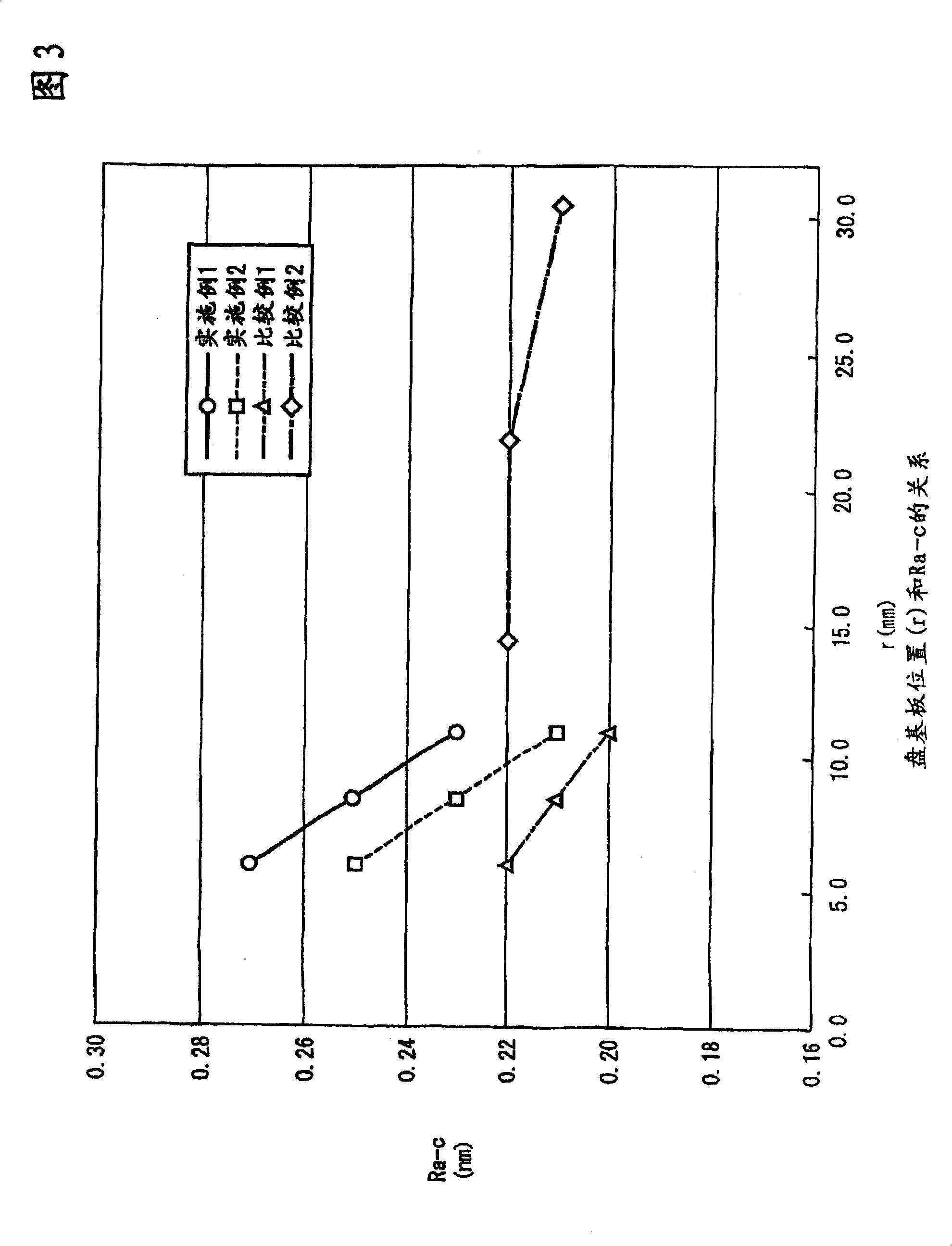

[0200] [Example 2 (Example of Glass Substrate for Magnetic Disk)]

[0201] As shown in (Table 1), Example 2 in which only the conditions of texture processing were changed in Example 1 was produced.

[0202] In this embodiment 2, the condition of texture processing is to use fabric belt as abrasive belt, use polycrystalline diamond slurry as abrasive (slurry), set the rotating speed of glass plate as 883 revolutions per minute, make glass plate The shaking (vibration) frequency of the glass plate was set to 7.8 Hz, the amplitude of the shaking (vibration) of the glass plate was set to 1 mm, and the processing weight by the pressure roller was set to 3.675 kg (1.5 pounds).

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com