A kind of wet-mixed mortar and preparation method thereof

A technology of wet-mixed mortar and mortar, which is applied in the field of building materials, can solve the problems of good workability, poor workability, short opening time of wet-mixed mortar, etc., and achieve the effect of preventing agglomeration and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

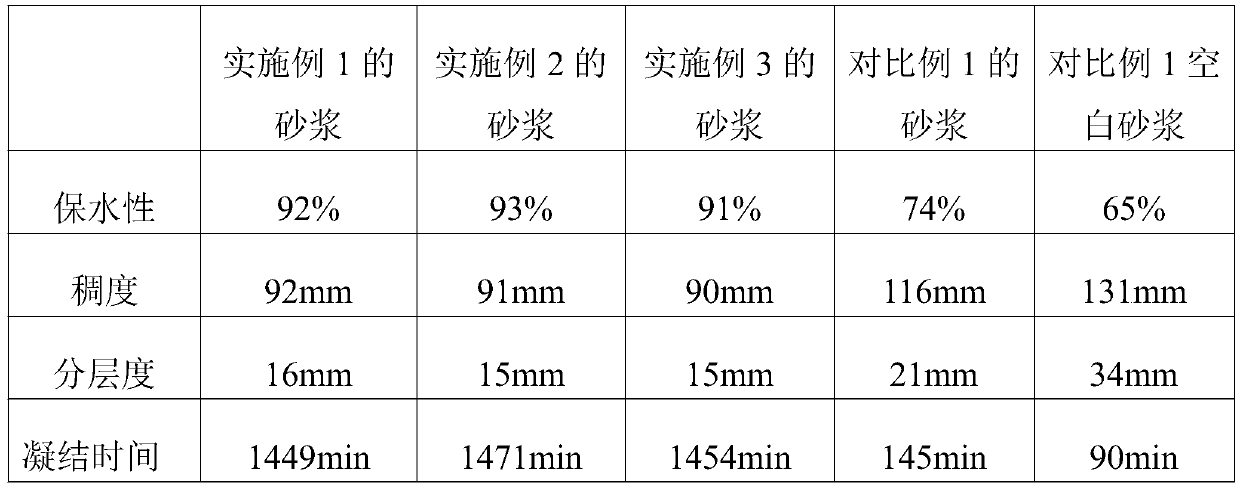

Examples

Embodiment 1

[0021] Mix aliphatic polyoxyethylene ether sodium sulfate, maltose beard and water at a mass ratio of 1:2:97, and stir evenly to obtain a mortar consistency regulator.

[0022] Mix sucrose, polycarboxylate superplasticizer, sodium gluconate, sodium α-olefin sulfonate and water at a mass ratio of 1:1.2:1:0.002:66, and stir evenly to obtain a mortar setting time regulator.

[0023] Mix 1.5kg of cement, 0.8kg of fly ash, 0.7kg of mineral powder, 12kg of sand and 1.7kg of water, and stir evenly to obtain blank mortar; add 0.03kg of mortar consistency regulator, and stir evenly; add 0.024kg of mortar setting time regulator , and stir evenly to obtain a wet-mixed mortar.

Embodiment 2

[0025] Mix 1.8kg cement, 0.9kg fly ash, 0.8kg mineral powder, 13kg sand and 1.8kg water, stir evenly to obtain blank mortar; add 0.046kg of mortar consistency regulator prepared in Example 1, and stir evenly; add Example 1 Prepare 0.035 kg of mortar setting time regulator, stir evenly to obtain wet-mixed mortar.

Embodiment 3

[0027] Mix 2kg cement, 1kg fly ash, 0.9kg mineral powder, 14kg sand and 1.9kg water, stir evenly to obtain a blank mortar; add 0.07kg of mortar consistency regulator prepared in Example 1, and stir evenly; add Example 1 to prepare Add 0.047kg of mortar setting time regulator and stir evenly to obtain wet-mixed mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com