Three-phase circulating fluidized bed photochemical reactor with a plurality of light sources and Fe/inorganic carrier catalyst preparation and method for processing waste water thereby

A technology of photochemical reactor and circulating fluidized bed, which is applied in chemical instruments and methods, chemical/physical processes, light water/sewage treatment, etc., can solve the problems of high iron sludge disposal cost, low organic mineralization, and large amounts of iron Waste sludge and other problems, to achieve the effect of simple operation, high salinity, and easy industrial scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

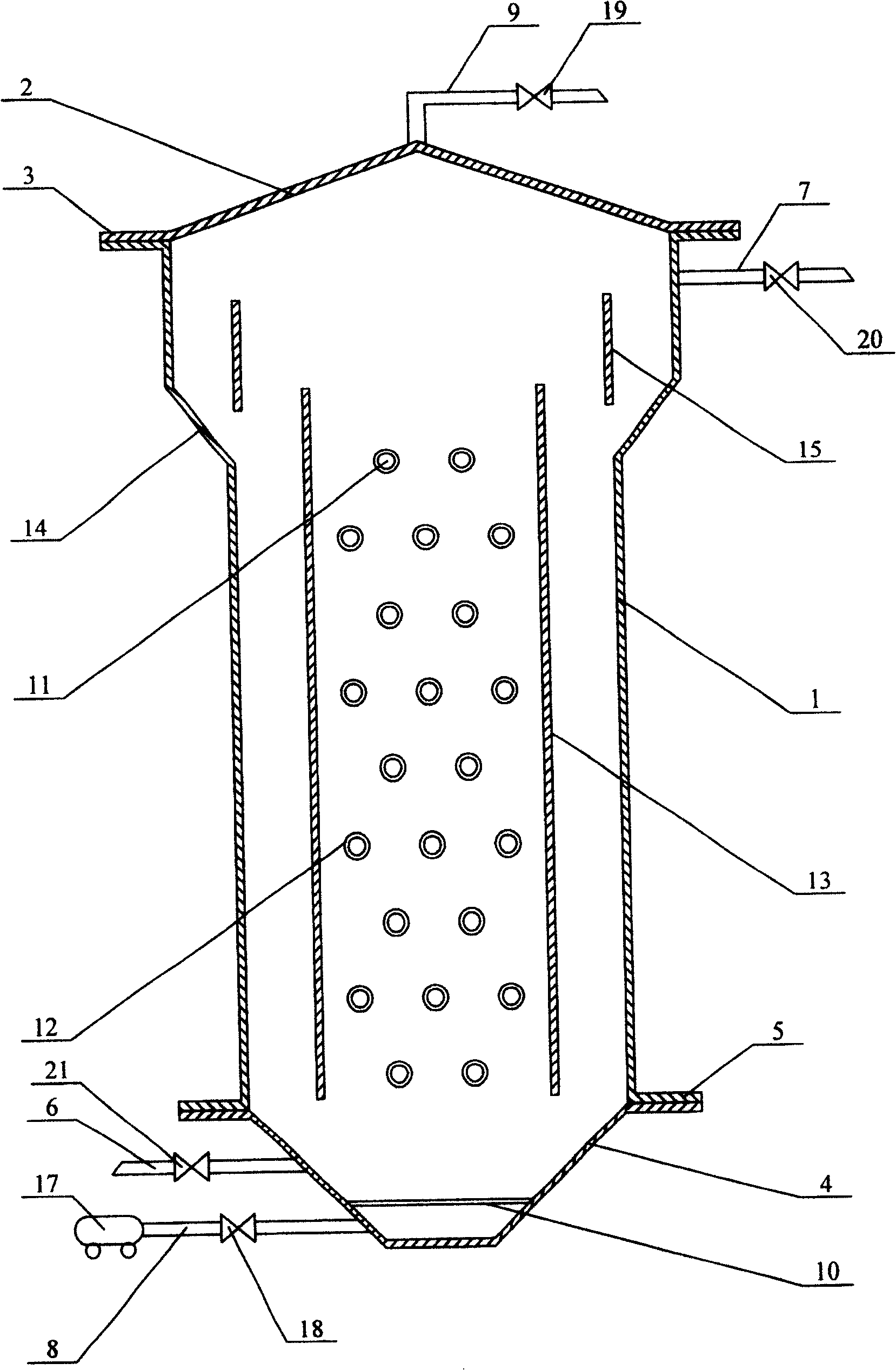

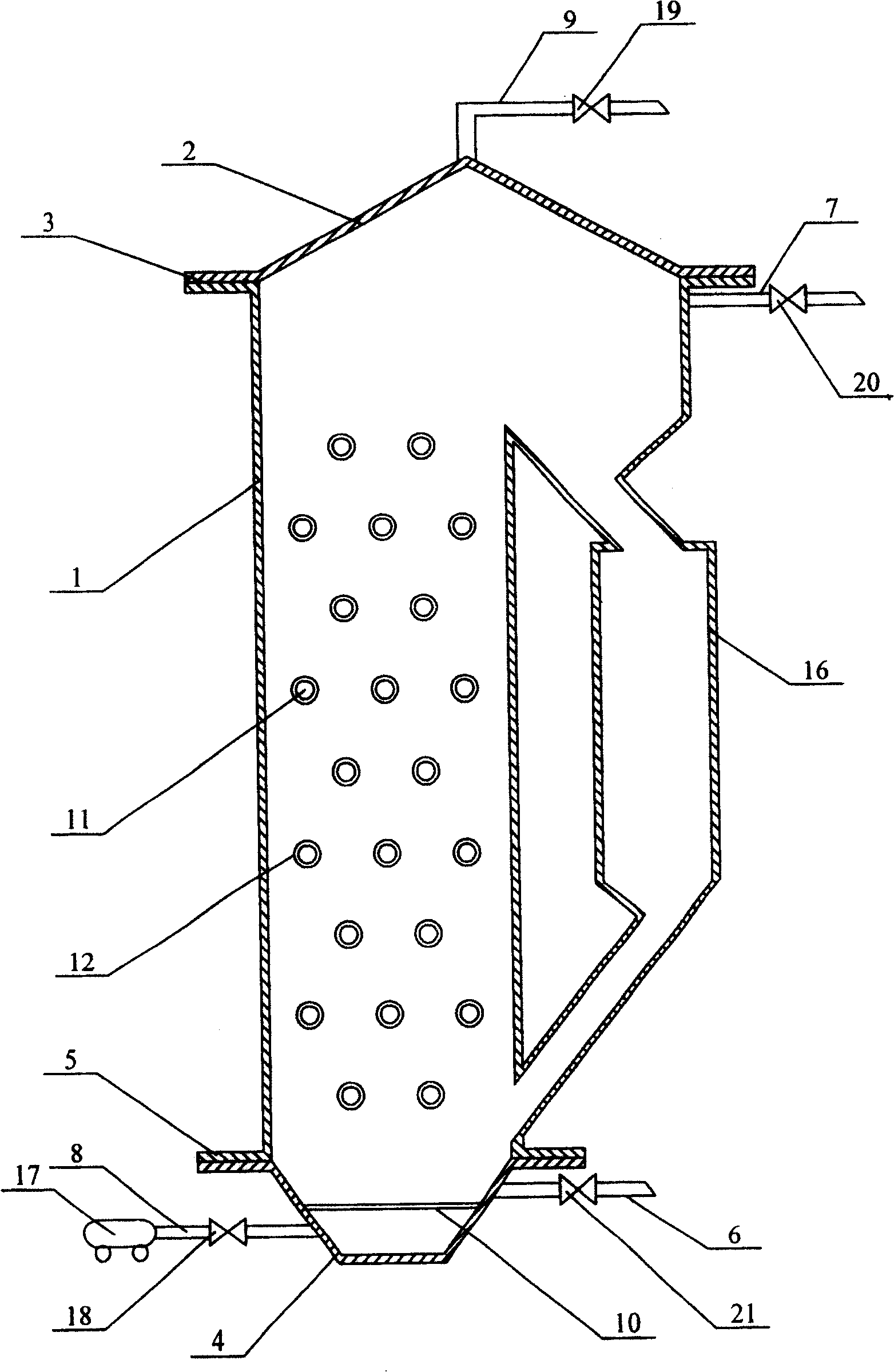

[0012] Specific implementation mode one: (see figure 1 , figure 2 ) The overall structure of the multi-light source three-phase circulating fluidized bed photochemical reactor in this embodiment is a cuboid, mainly composed of a cylinder body 1, an upper head 2, an upper head flange 3, a lower head 4, and a lower head flange 5 , water inlet pipe 6 with water inlet valve 21, water outlet pipe 7 with water outlet valve 20, air inlet pipe 8 with air inlet valve 18 and air pump 17, air outlet pipe 9 with air outlet valve 19, porous aeration Plate 10, ultraviolet lamp 11 and quartz sleeve 12; the upper head 2 and the cylinder body 1 are connected through the upper head flange 3, the air inlet of the air outlet pipe 9 communicates with the top of the upper head 2, and the outlet pipe 7 The water inlet communicates with the upper part of the cylinder body 1, and a plurality of quartz sleeves 12 are horizontally installed in the cylinder body 1, and the two end faces of the quartz s...

specific Embodiment approach 2

[0013] Specific implementation mode two: (see figure 1 ) In the multi-light source three-phase circulating fluidized bed photochemical reactor of the present embodiment, a deflector 13, an enlarged funnel 14 and an outlet baffle 15 are added, and the two end faces of the deflector 13 are fixedly connected to the inner wall of the cylinder 1, The lower end of the enlarged funnel 14 is fixedly connected with the upper end of the cylinder body 1 , the upper head 2 is connected with the enlarged funnel 14 through the upper head flange 3 , and the two ends of the outlet baffle 15 are fixedly connected with the inner wall of the enlarged funnel 14 . Others are the same as in the first embodiment.

[0014] The structure of the reactor in this embodiment constitutes a multi-light source three-phase internal circulating fluidized bed photocatalytic reaction system. In this embodiment, a downflow zone is formed between the deflector 13 of the reactor and the inner wall of the cylinder ...

specific Embodiment approach 3

[0015] Specific implementation mode three: (see figure 2) In the multi-light source three-phase circulating fluidized bed photochemical reactor of the present embodiment, a solid phase conveying pipe 16 is added, and the solid phase conveying pipe 16 is installed outside the cylinder body 1, and the upper end of the solid phase conveying pipe 16 is connected with the cylinder body 1 The upper part of the solid phase delivery pipe 16 is fixedly connected to the bottom of the cylinder; Others are the same as in the first embodiment.

[0016] The structure of the reactor in this embodiment constitutes a multi-light source three-phase external circulating fluidized bed photocatalytic reaction system. In this embodiment, an upflow zone is formed between the inner walls of the reactor cylinder 1, a downflow zone is formed between the inner walls of the solid phase delivery pipe 16, a solid-liquid separation zone is formed above the reactor, and a reflux zone is formed in the lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com