Backlight lamp device and liquid crystal display device

A technology of backlight and light-emitting part, which is applied to display devices, lighting devices, components of lighting devices, etc., can solve the problems of increasing the thickness of backlight devices, and achieve miniaturization, thickness reduction, and uniform surface lighting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings. In addition, in the following description, terms indicating a predetermined direction (such as "up", "down", "right", "left") and other terms containing these terms (such as "above", "below" , "right side", "left side"), however, these terms are for easy understanding of the present invention with reference to the drawings, and the technical scope of the invention is not limited by these terms. Therefore, the embodiment of the present invention described below is turned upside down, or rotated to a predetermined angle (eg, 90 degrees) in any direction (eg, clockwise or counterclockwise) also falls within the technical scope of the present invention.

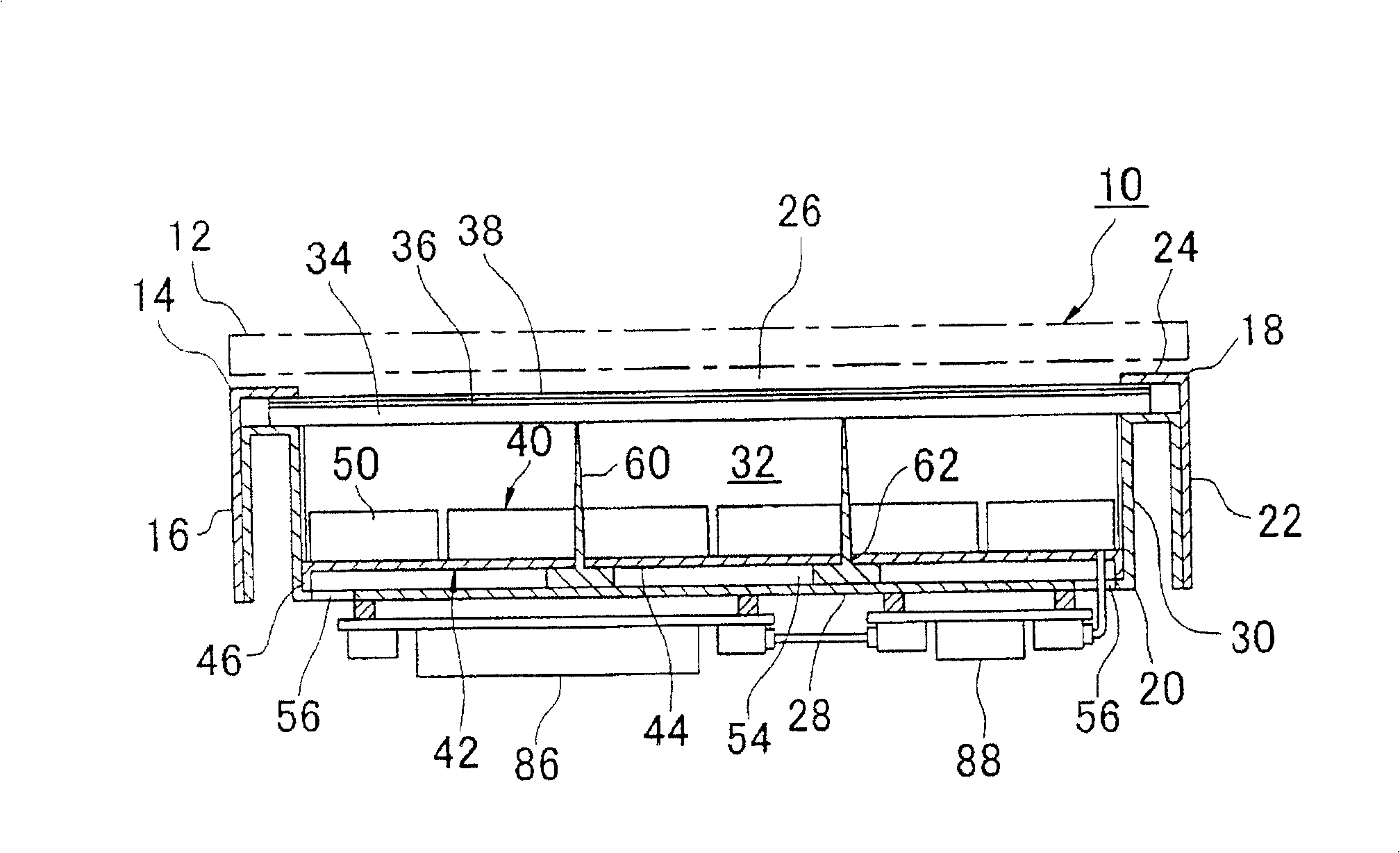

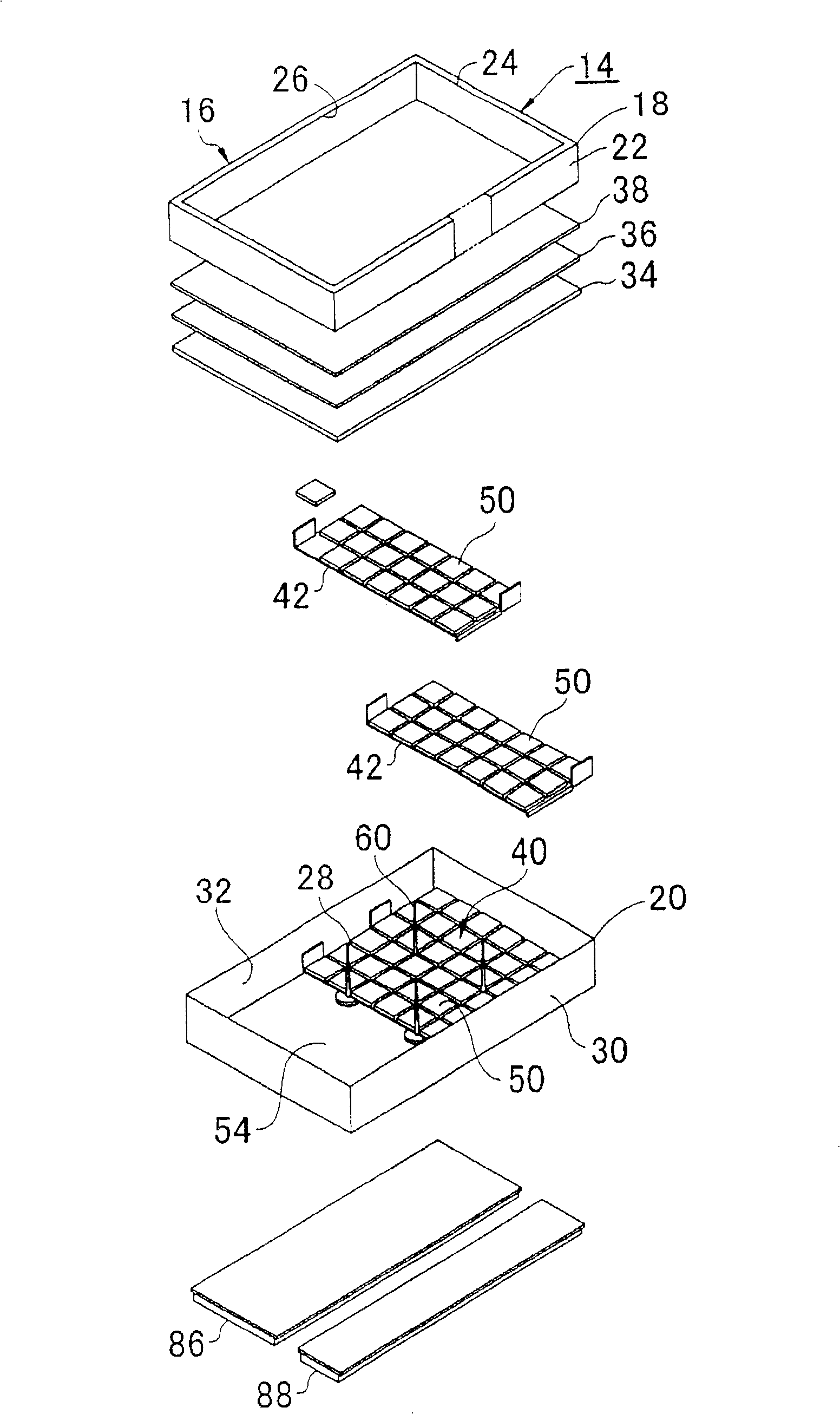

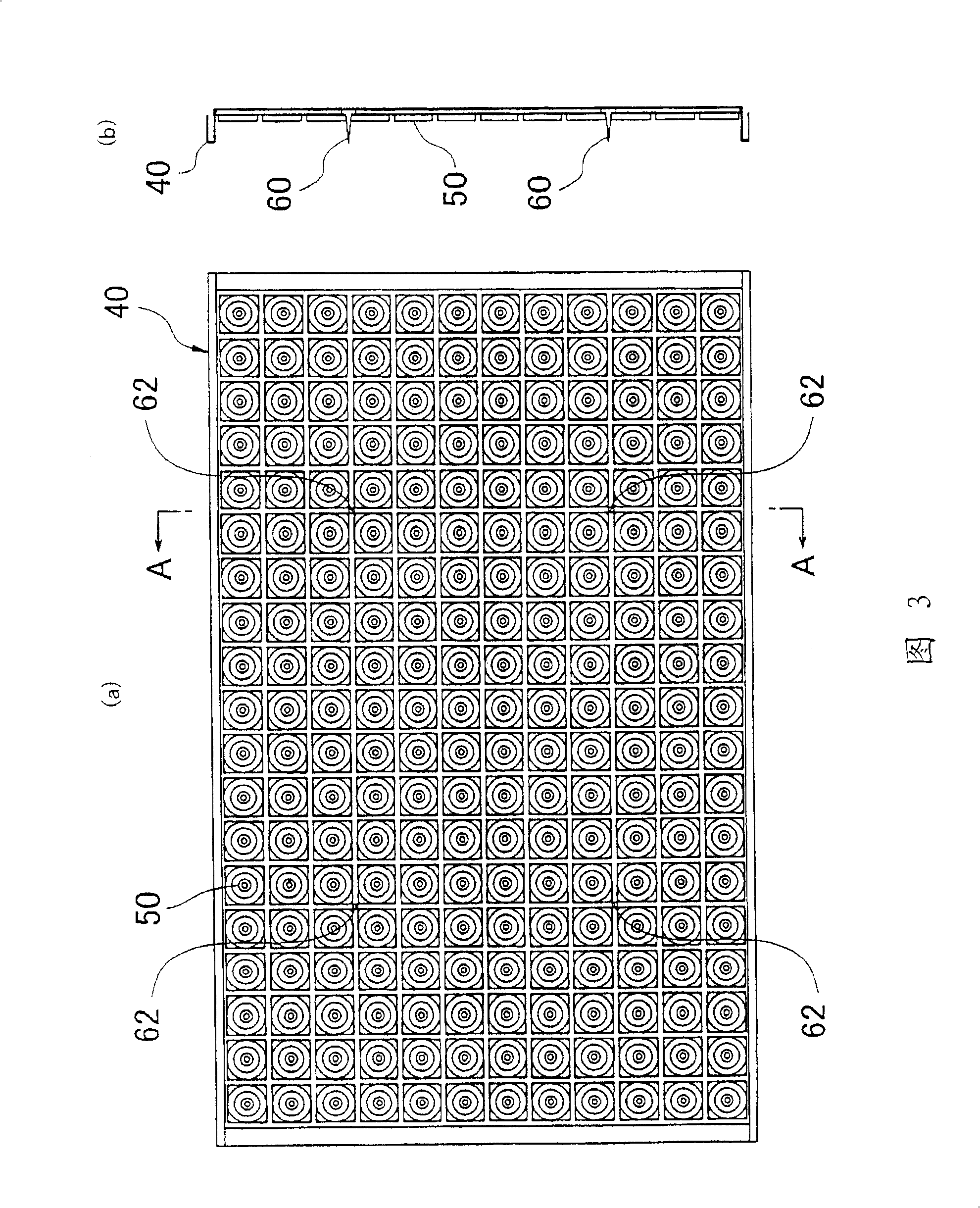

[0038] figure 1 It is a cross-sectional view of a liquid crystal display device. The illustrated liquid crystal display device 10 has a liquid crystal panel 12 and a backlight device 14 disposed behind the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com