Series organic luminescent assembly and method for manufacturing same

A technology of light-emitting components and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., to achieve the effects of increasing the spacing distance, reducing the current, and preventing shielding scratches or water-absorbing material crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] Specific embodiments are listed below to describe the content of the present invention in detail, and drawings are used as auxiliary descriptions. The symbols mentioned in the description refer to the figure numbers.

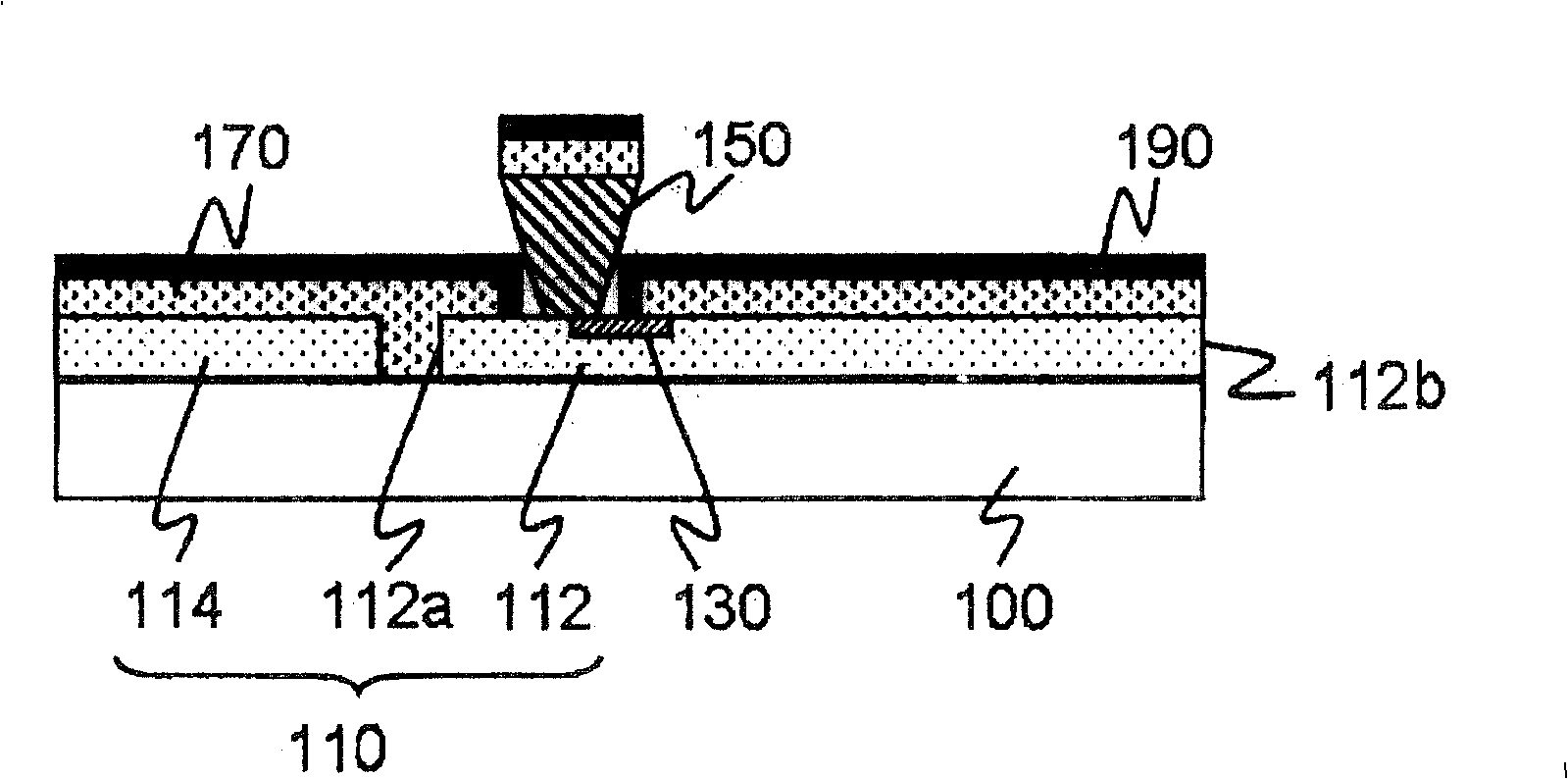

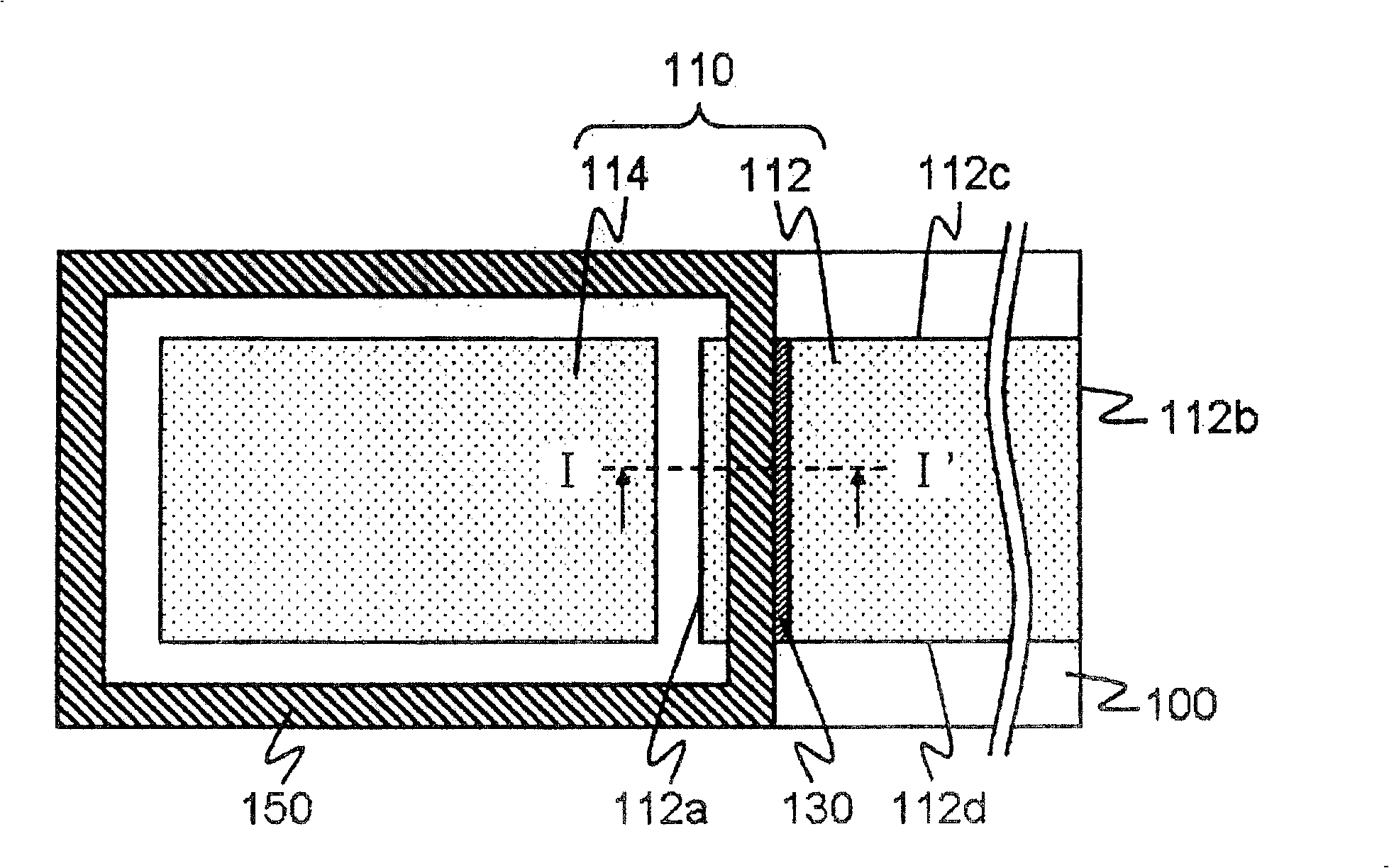

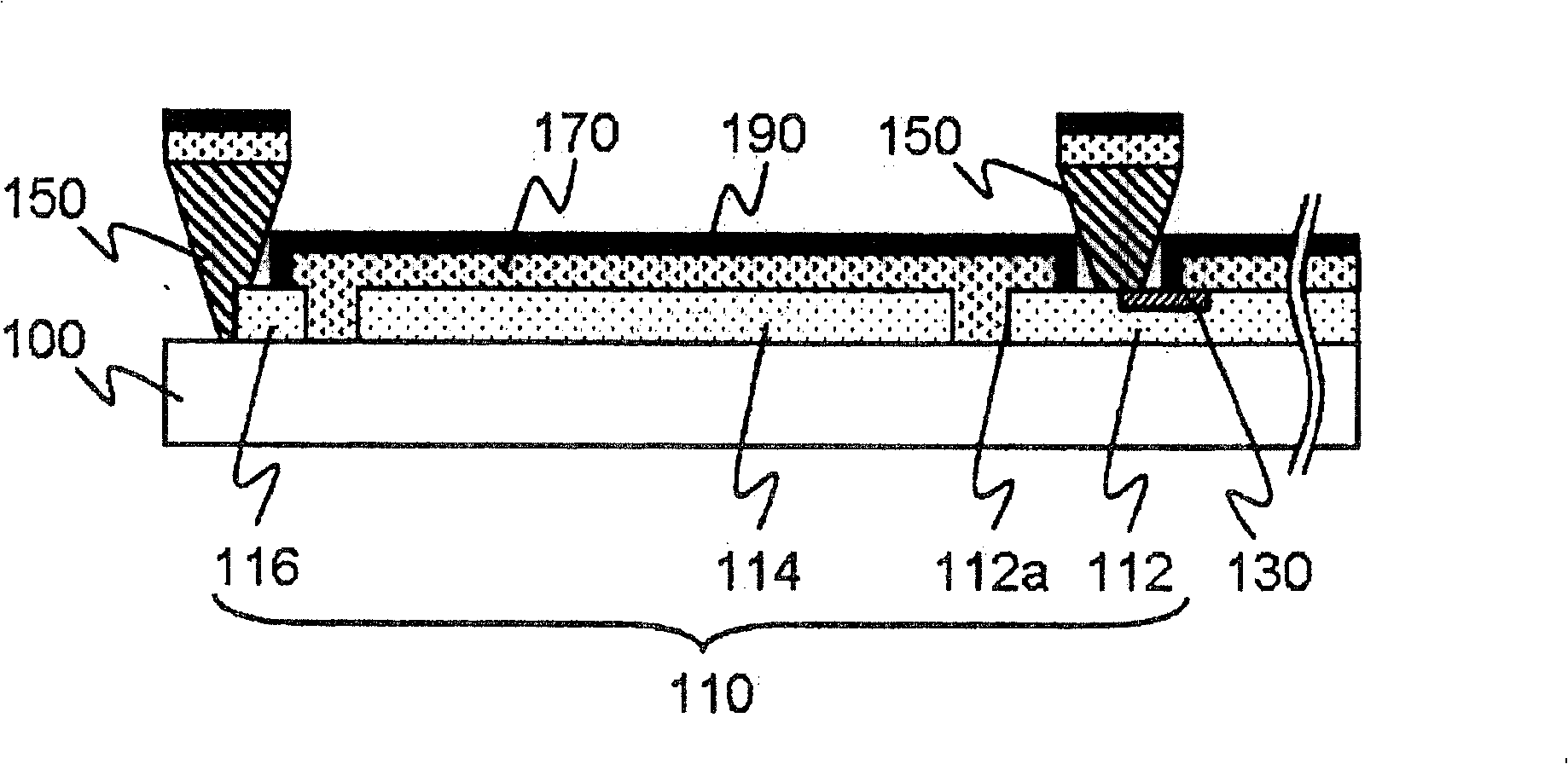

[0078] refer to Figure 1A , Figure 1B , which is a tandem organic light emitting device according to the present invention, comprising: a first electrode 110 , an insulating layer 130 , a partition wall 150 , a light emitting layer 170 and a second electrode 190 .

[0079] exist Figure 1B The light-emitting layer 170 and the second electrode 190 are not shown in the figure, so as to understand the arrangement positions of the first electrode 110, the insulating layer 130 and the partition wall 150, wherein Figure 1A The structure in which the light-emitting layer 170 and the second electrode 190 are omitted is Figure 1B The section of the line I-I' in the middle.

[0080] The first electrode 110 is disposed on a substrate 100 and includes a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com