Floating structure and method for producing said floating structure comprising prefabricated room units and a method of forming prefabricated room units and said prefabricated room units

A technique for floating structures and rooms, applied in the fields of floating structures, for producing said floating structures including prefabricated room units, for forming prefabricated room units and said prefabricated room units, capable of solving dangers, production Floating structure hazards, fire hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

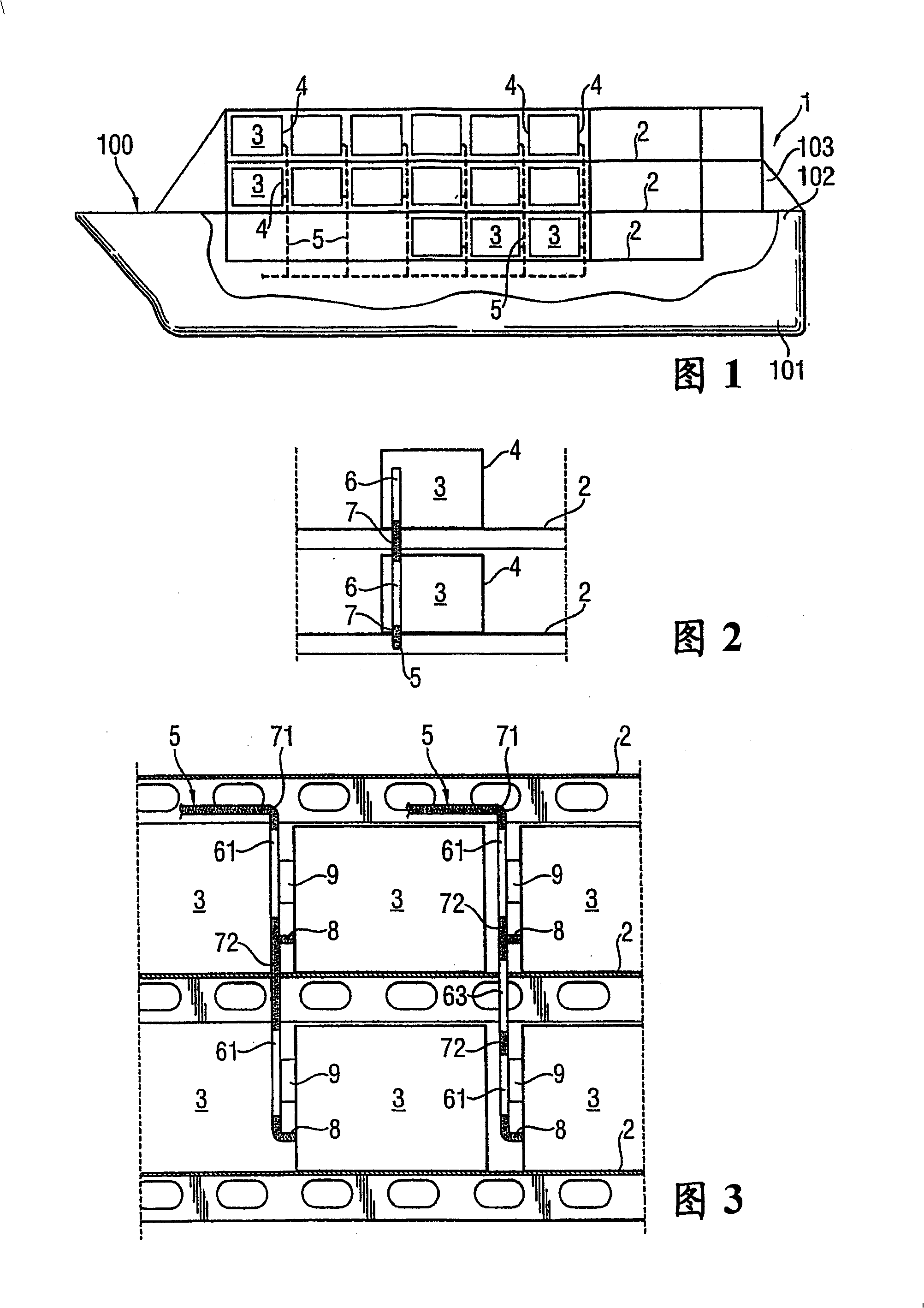

[0022] In FIG. 1 , the floating structure is indicated by reference numeral 1 . The floating structure comprising the main part 100 is provided with a deck structure or a corresponding support structure 2 on which a number of prefabricated, at least partially assembled room units 3 are arranged. These room units 3 are provided in the lower part 101 and the upper part 103 of the main part 100 of the floating structure 1 . In the figure, dashed lines show in a simplified manner how the devices related to the assembly of the room unit 3 and the components related to the system 5 of the floating structure are arranged outside the boundary surface 4 of the room unit 3, which will be described in more detail below. These settings according to the invention are discussed.

[0023] The floating structure may be, for example, a sea vessel, such as a ship, an oil well facility, or some other corresponding structure. Therefore, the subject matter related to the embodiments described be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com