Supercritical fluid assistant micropore injection moulding apparatus

A technology of supercritical fluid and injection molding equipment, applied in the field of injection molding equipment, can solve the problems of difficult popularization and application in a wide range, large floor space, long processing cycle, etc., to achieve wide application range, small floor space, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

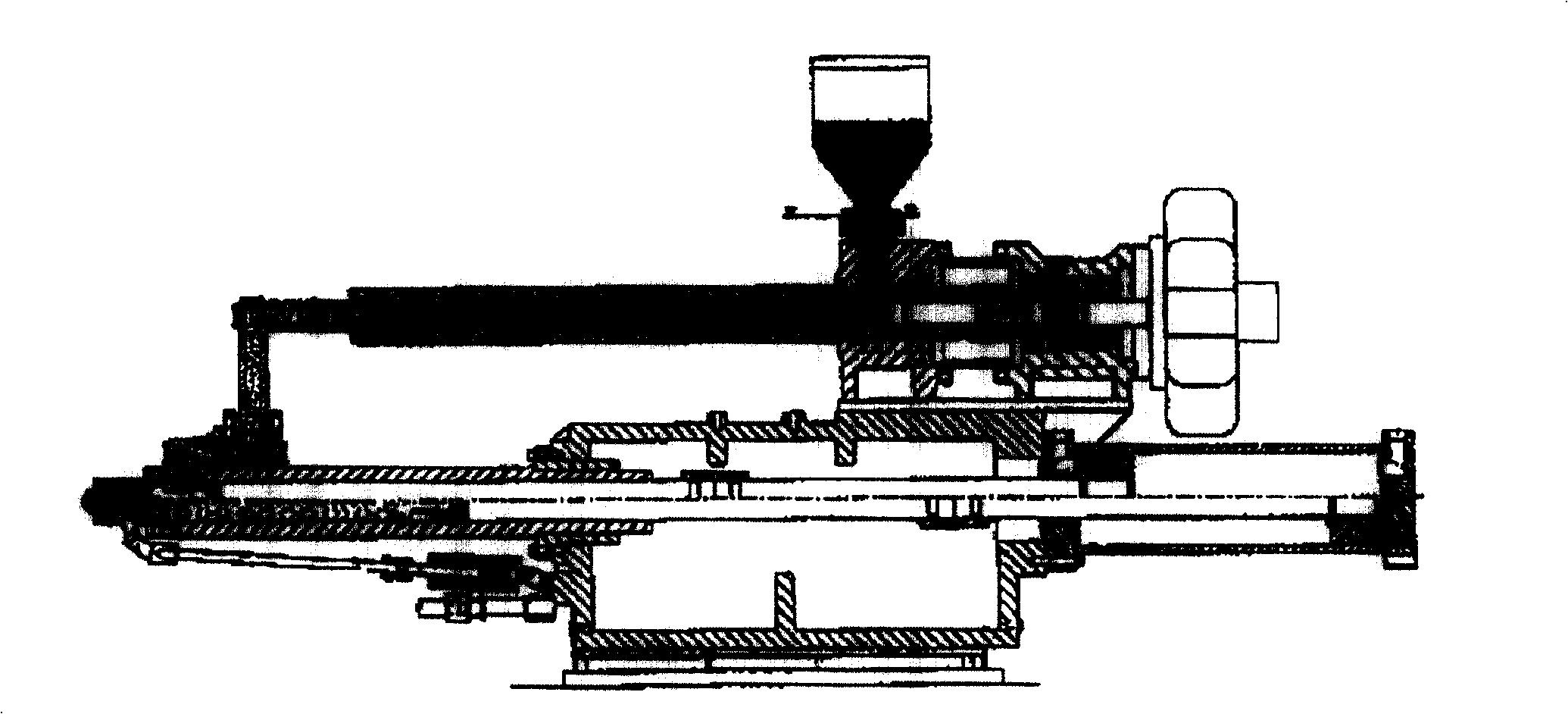

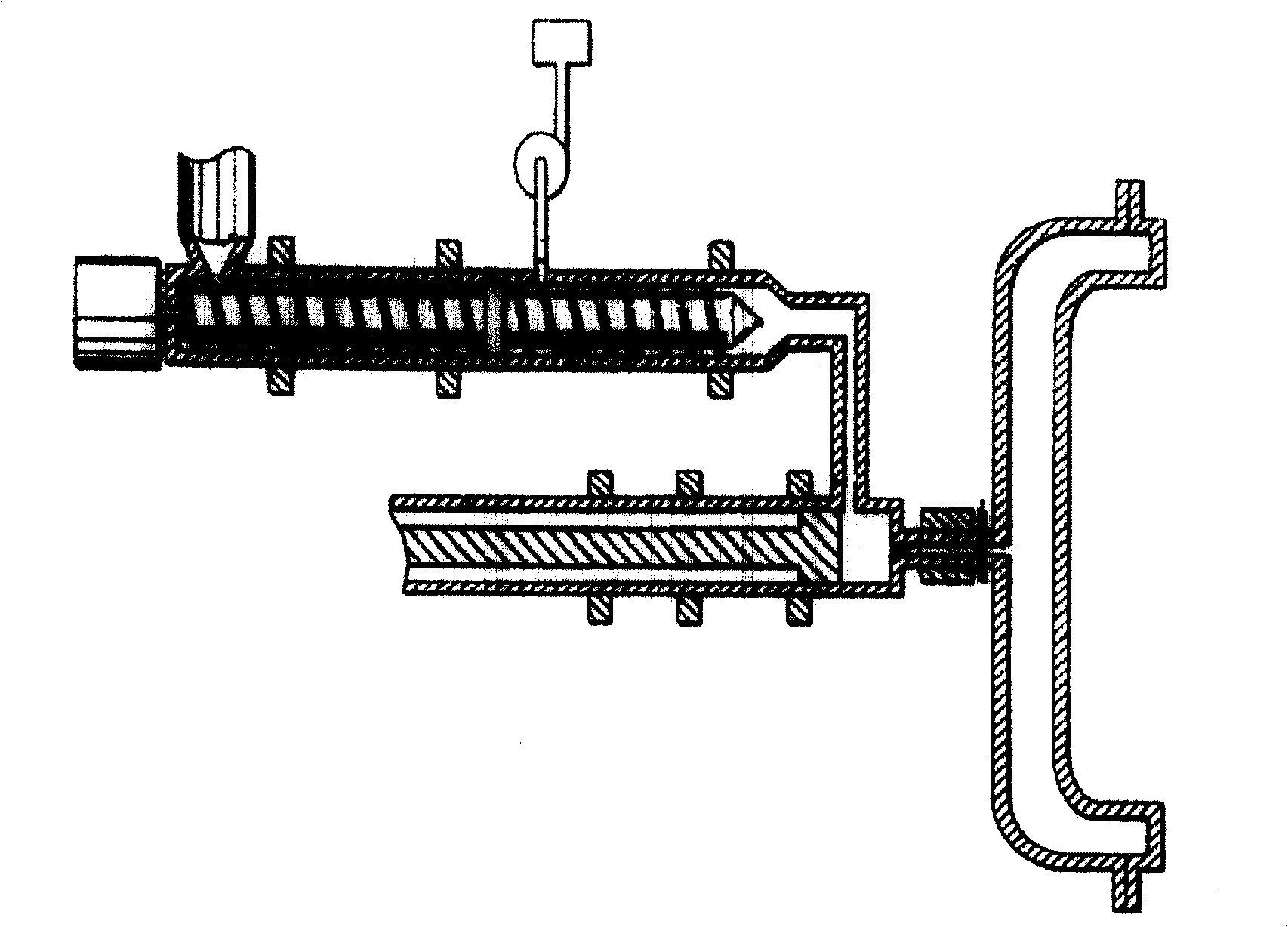

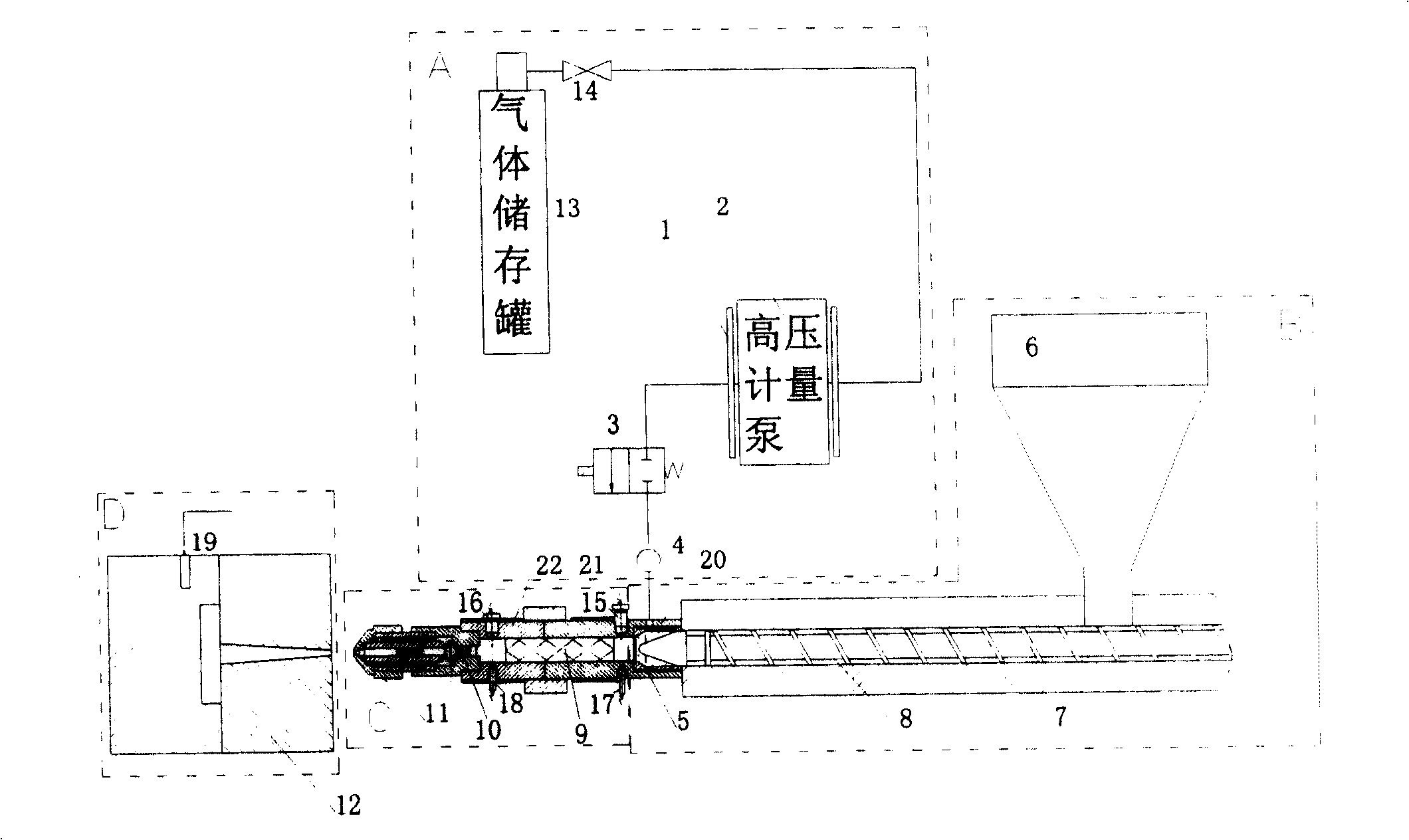

[0026] Figure 3 ~ Figure 8 shows the concrete structure of the present invention, by image 3 It can be seen that the supercritical fluid-assisted microporous injection molding equipment includes injection molding machine B, mixing type self-locking nozzle assembly C, mold system D and supercritical fluid metering and delivery device A; mixing type self-locking nozzle assembly C and injection molding The machine B is connected through the gas injection flange 20, and the gas injection flange 20 is connected with the supercritical fluid metering and delivery device A at the same time; the injection molding machine B is an ordinary injection molding machine, including a barrel 7, a hopper 6, a screw 8. The rear end of the barrel 7 is connected to the hopper 6, and the outer periphery of the barrel 7 is equipped with a temperature-control heating ring (not shown in the figure), and the inside of the barrel 7 is provided with an injection screw 8 capable of rotating and reciproca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com