Big-flow self-priming centrifugal pump

A self-priming pump and centrifugal pump technology, applied in the field of large-flow self-priming centrifugal pumps, can solve the problems of increasing the surface area of the jet, low pump efficiency, slow water filling speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

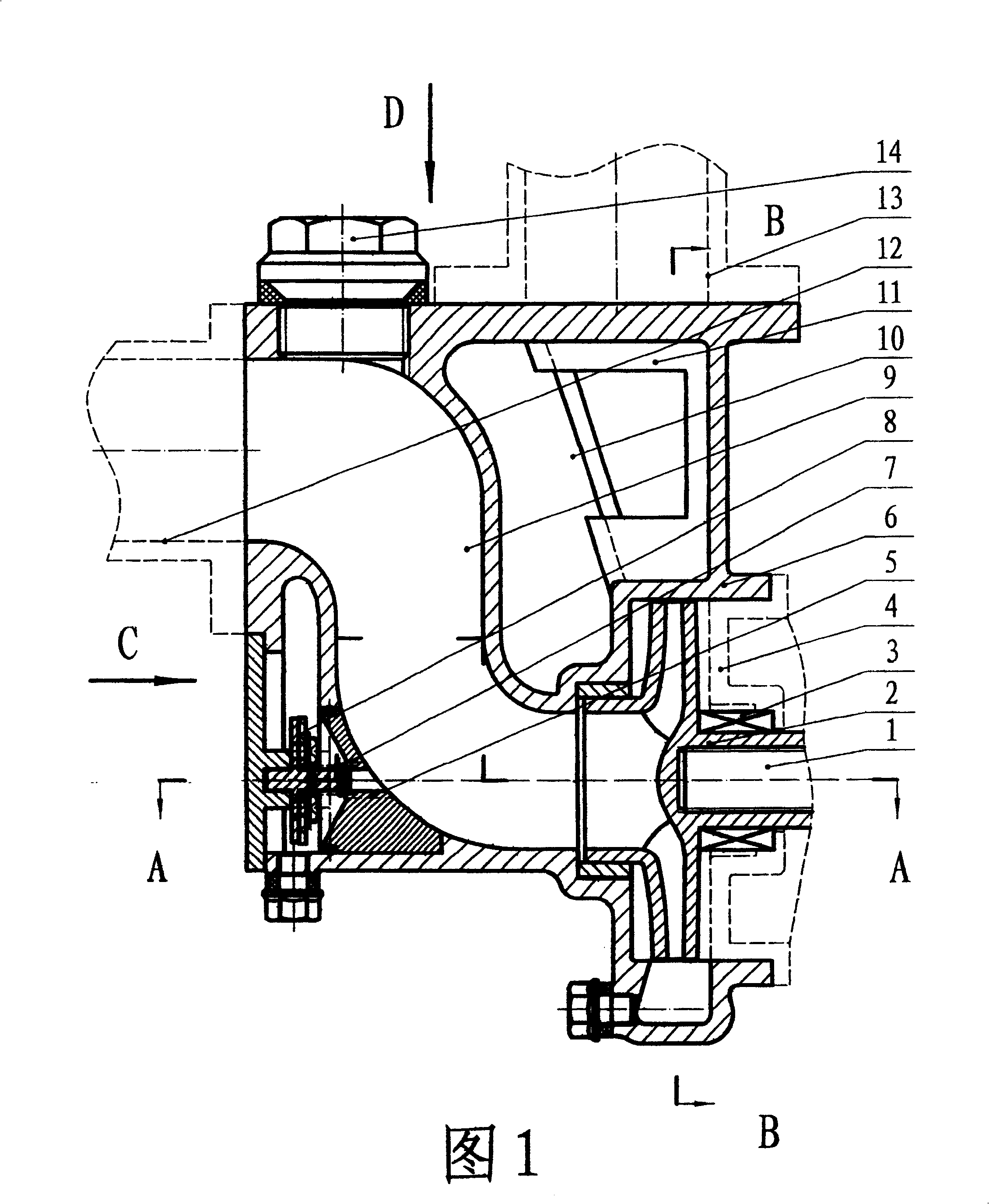

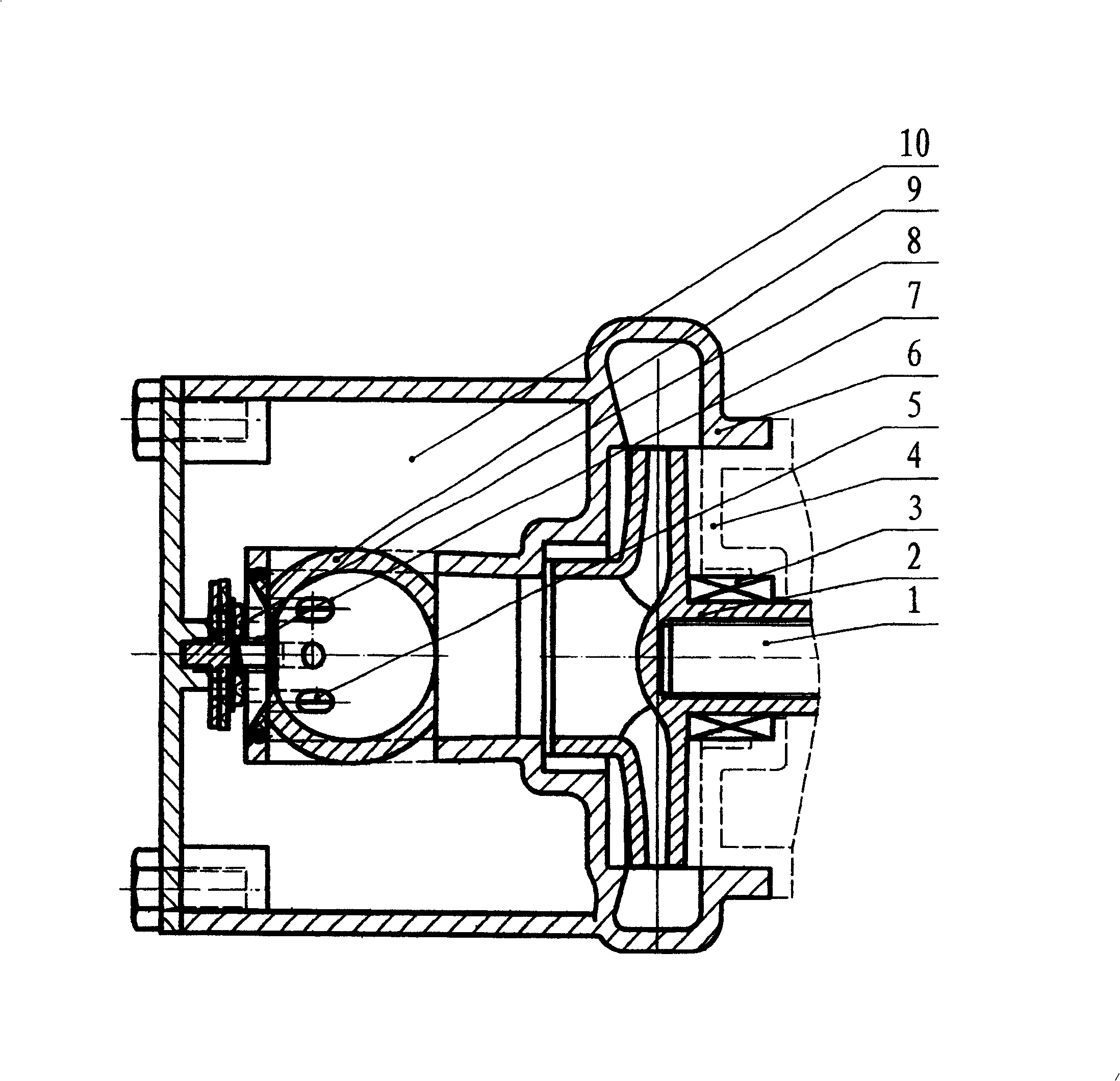

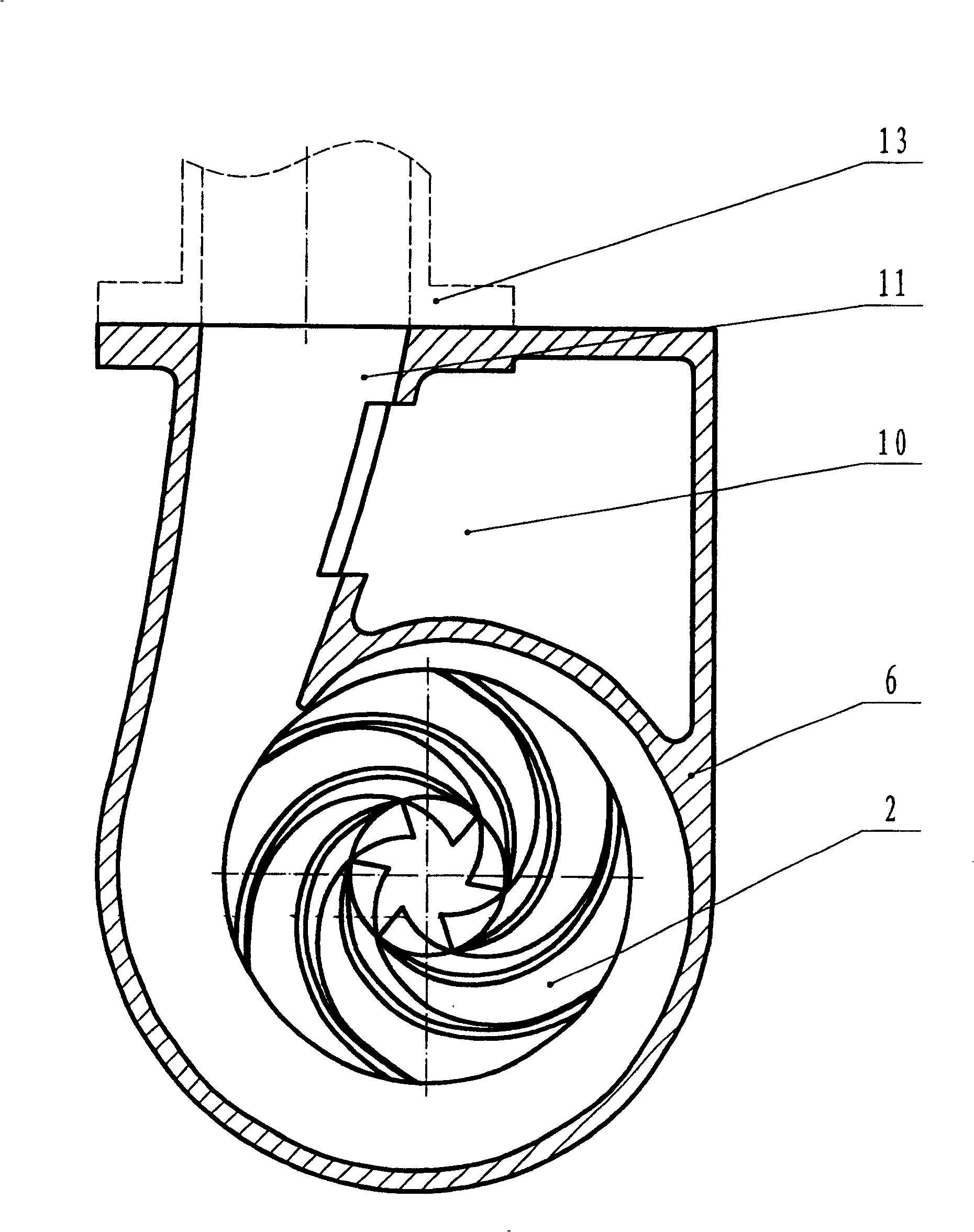

[0025] In Fig. 1, impeller shaft (1), impeller (2), shaft seal (3), rectangular nozzle group (5), S-shaped elbow (9), water pump outlet diffuser pipe (11), water pump outlet diffuser The large channel (10) between the pipe and the inlet of the nozzle forms the main part of this embodiment together with the self-priming pump housing (6), and the spring (7) and valve plate (8) are used to close the opening of the rectangular nozzle group (5). The inlet can improve the water pump efficiency of the present embodiment. The irrigation hole plug (14) is used to open the irrigation hole before starting, and the working machine (electric motor or internal combustion engine, etc.) passes through the working machine coupling frame (4) and the impeller shaft (1) Integrating with the present embodiment, the water inlet pipeline (12) is connected to the upper end of the S-shaped elbow (9), and the water outlet pipeline (13) is connected to the top of the outlet diffusion pipe (11) of the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com