Method for preparing three dimension stereo sandwiched carrier composite plate

A three-dimensional, composite board technology, applied in the field of composite boards, can solve the problems of easy delamination of composite boards, achieve uniform resin infiltration, save raw material consumption, and stabilize resin content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

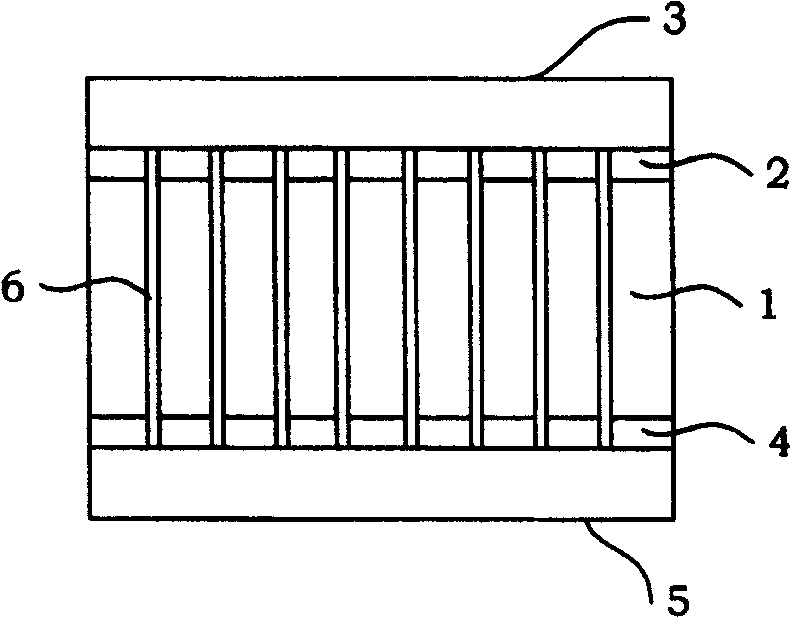

[0024] The composite panel obtained by the preparation method of the present invention is characterized in that: the load-bearing columns 6 (fiber bundles) pass through the superimposed upper panel inner layer 2, lightweight core material 1 and lower panel inner layer 4, and the load-bearing Columns 6 can be woven in regularly or irregularly, and the multiple load-bearing columns 6 woven in can be arranged uniformly in the thickness direction of the product, or irregularly distributed according to the requirements of use. . The sizes of the inner layer 2 of the upper panel, the inner layer 4 of the lower panel, the outer layer 3 of the upper panel and the outer layer 5 of the lower panel are adapted to the lightweight core material 1 . The combination between the inner layer 2 of the upper panel and the outer layer 4 of the upper panel, and the inner layer 3 of the lower panel and the outer layer 5 of the lower panel is formed by infiltrating the resin introduced by the vacuum...

Embodiment 1

[0027] Example 1: Preparation of traditional glass fiber sandwich structure composite panel

[0028] Composite panel structure

Selection of raw materials

Upper panel outer layer 3

Glass fiber mat 30g / m 2 + Two-dimensional glass fiber fabric 2000g / m 2 ;

Upper panel inner layer 2

Two-dimensional glass fiber fabric 500g / m 2 ;

Inner layer of lower panel 4

Two-dimensional glass fiber fabric 500g / m 2 ;

Lower panel outer layer 5

Glass fiber mat 30g / m 2 + Two-dimensional glass fiber fabric 2000g / m 2 ;

Lightweight core material 1

Phenolic foam, density 0.08±0.002g / cm 3 ;

resin content

36.2%。

[0029] The processing size of the composite board takes the length and width of the lightweight core material 1 as a reference. In this example, the size of the phenolic foam lightweight core material 1 is taken as 1200×2400×20mm, and the outer layer 3 of the upper panel and the outer layer of the ...

Embodiment 2

[0032] Example 2: Preparation of high flame-retardant glass fiber three-dimensional three-dimensional sandwich load-bearing composite board

[0033] Composite panel structure

Selection of raw materials

Upper panel outer layer 3

Glass fiber mat 30g / m 2 + Two-dimensional glass fiber fabric 2000g / m 2 ;

Upper panel inner layer 2

Two-dimensional glass fiber fabric 500g / m 2 ;

Inner layer of lower panel 4

Two-dimensional glass fiber fabric 500g / m 2 ;

Lower panel outer layer 5

Glass fiber mat 30g / m 2 + Two-dimensional glass fiber fabric 2000g / m 2 ;

Lightweight core material 1

Phenolic foam, density 0.08±0.002g / cm 3 ;

resin content

36.5%;

Bearing column 6

4800TEX fiberglass strands.

[0034] The processing size of the composite board takes the length and width of the lightweight core material 1 as a reference. In this example, the size of the non-powdering type phenolic foam lig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com