Method for synthesizing alkali modified molecular sieve containing titanium

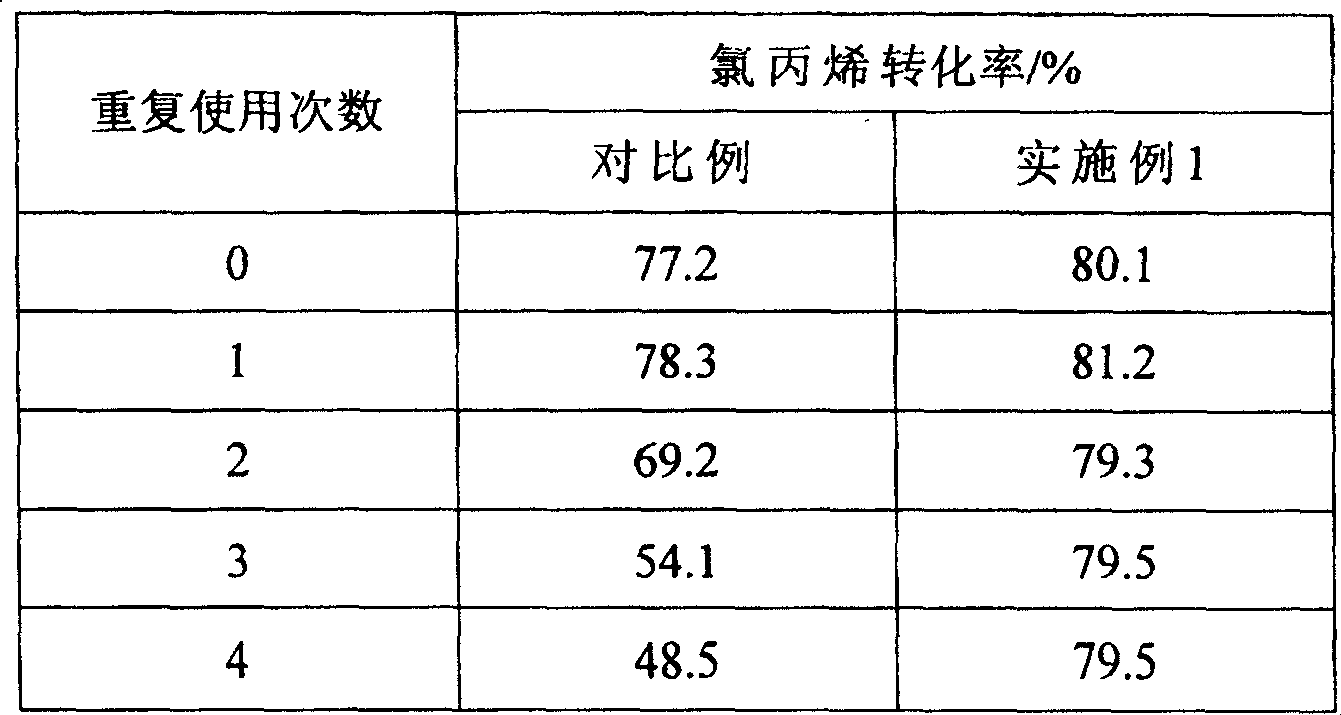

A technology of titanium molecular sieve and synthesis method, which is applied in the synthesis of titanium-containing molecular sieve and the synthesis field of Ti-MWW molecular sieve, can solve the problem of low stability of catalytic activity of Ti-MWW molecular sieve, and achieves simple operation and stable catalytic activity. Improve the effect of easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the literature (Chemistry Letters, 2000: 774), SiO is composed of sol 2 / TiO 2 Ti-MWW molecular sieves were synthesized with a molar ratio of 20 as raw materials.

[0021] In the first step, Ti-MWW molecular sieve: the weight ratio of basic compound solution=1:5, the concentration of basic compound solution is 5.6mol / l, and basic compound is piperidine; In the second step, hydrothermal treatment first The temperature and time of the reaction mixture prepared in this step were 170°C and 24 hours, respectively.

Embodiment 2

[0023] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0024] In the first step, the basic compound is hexamethyleneimine.

Embodiment 3

[0026] Implementation process is except following difference, and all the other are all the same with embodiment 1:

[0027] In the first step, the basic compound is a mixture of piperidine and hexamethyleneimine, and the weight ratio of the two is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com