Chemical preparation method of Ag nanoparticle

A silver nanometer and particle technology, applied in the field of solution chemical method synthesis, can solve the problems of complex structure, difficult reaction, high production cost, etc., and achieve the effect of abundant sources and good modification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

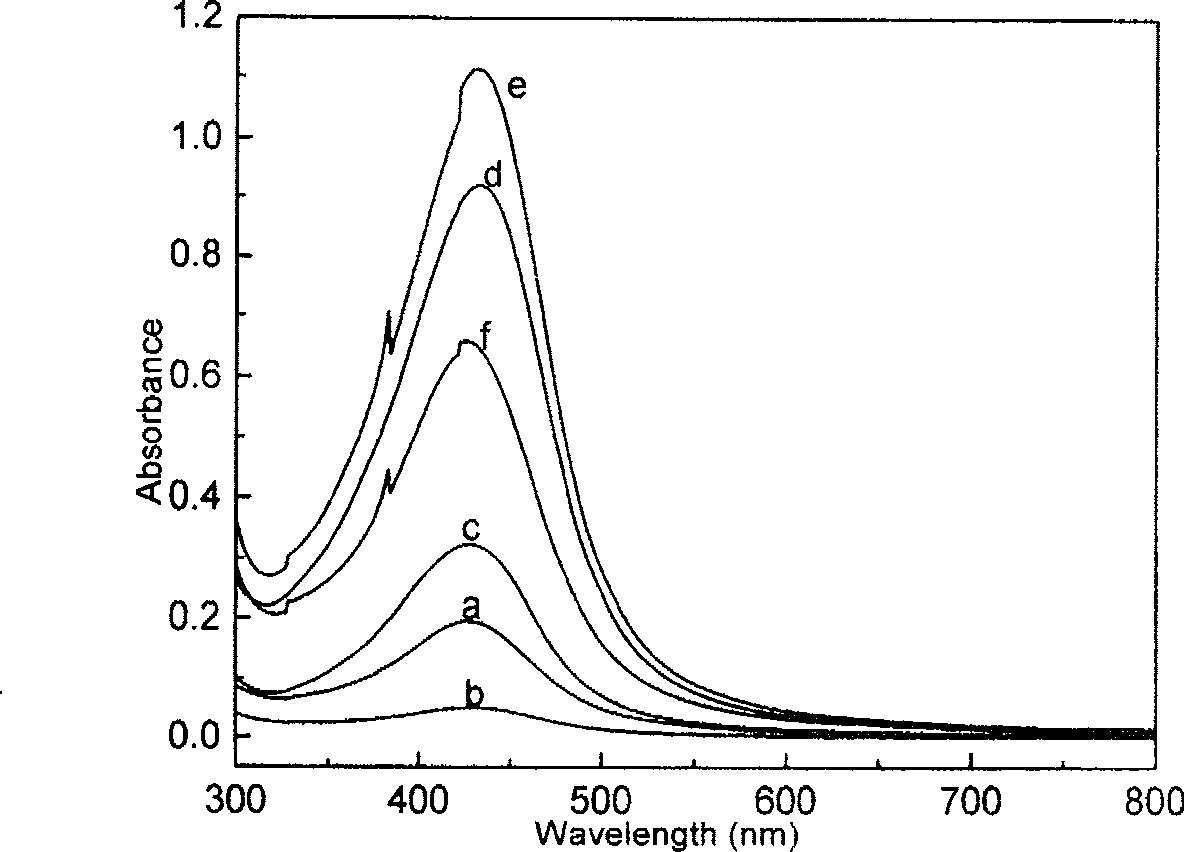

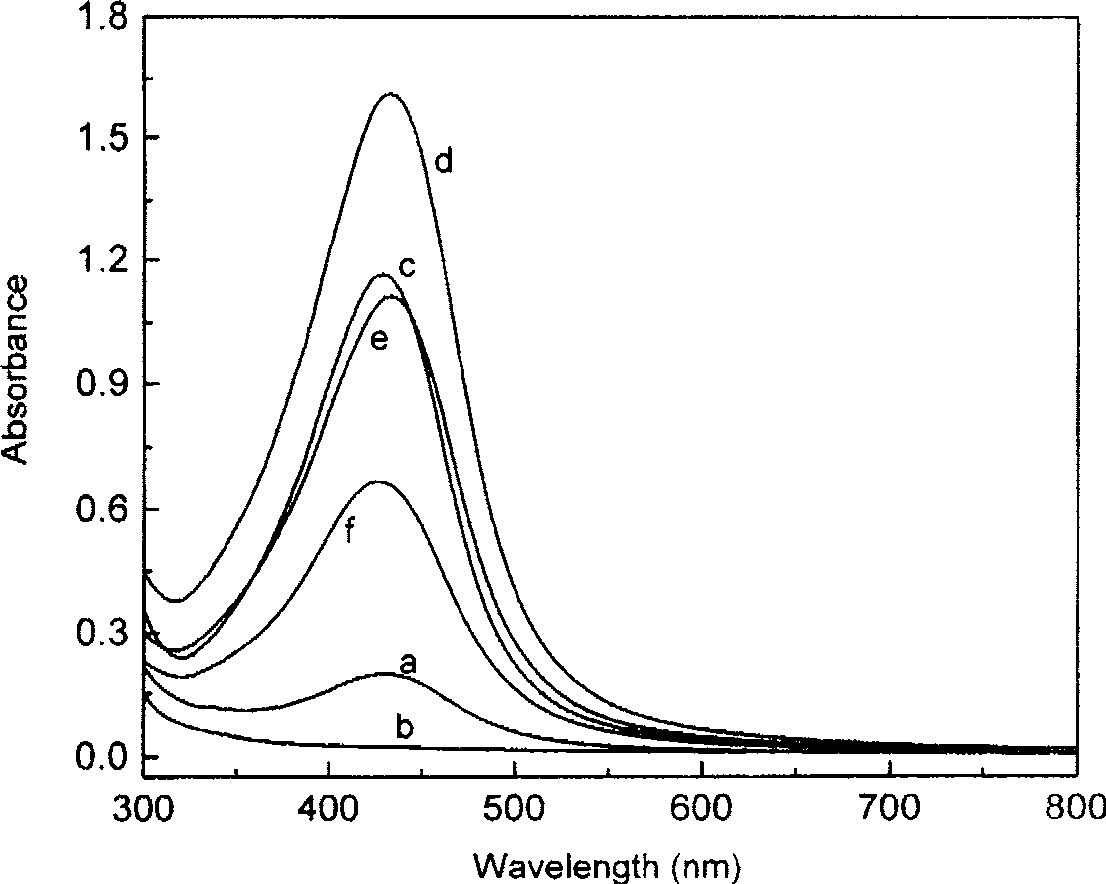

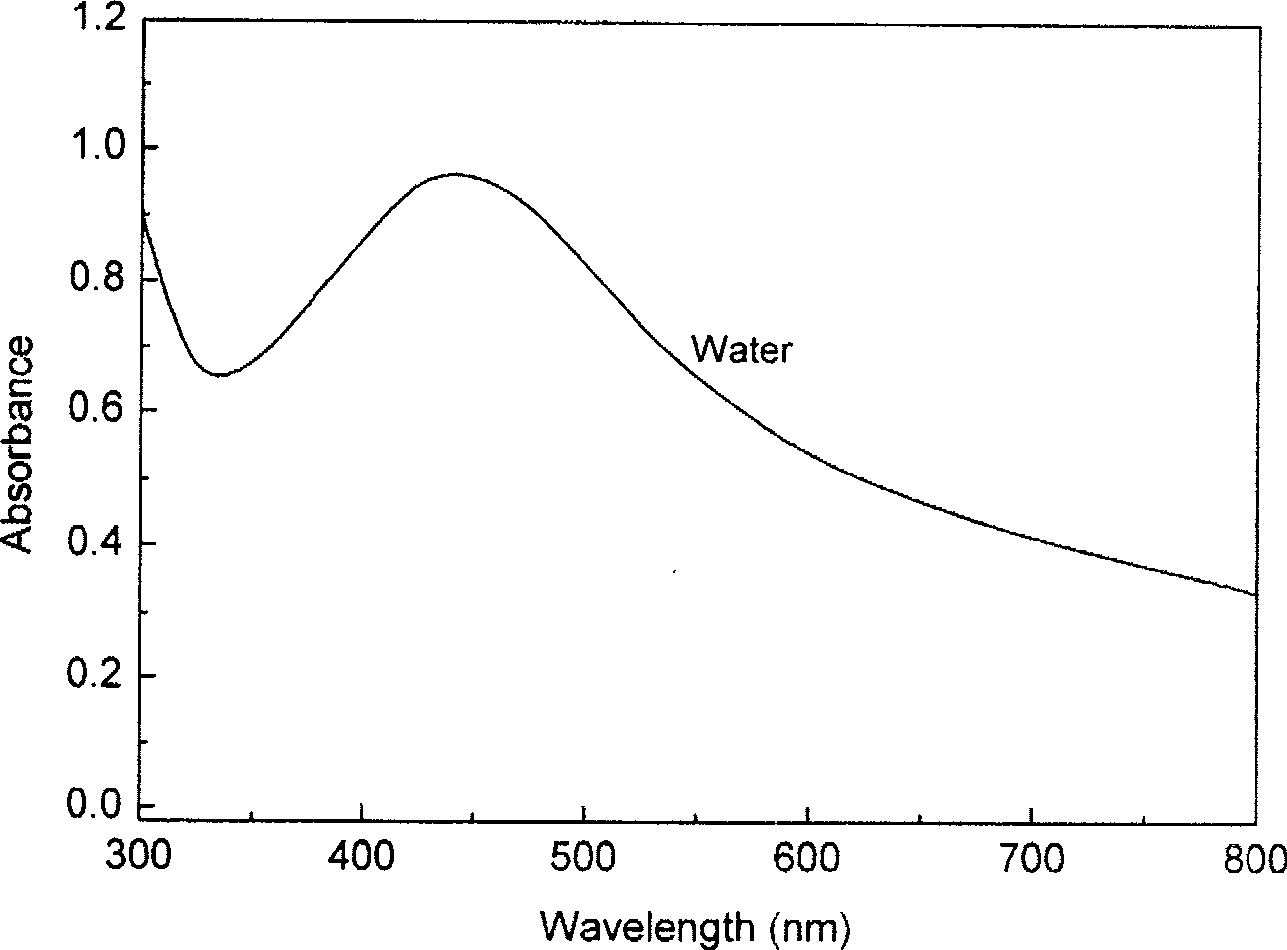

[0019] Add 122mg of sodium oleate, 34mg of silver nitrate, and 20ml of toluene into a 250ml three-necked reaction flask. After the temperature is slowly raised to 80°C, react at a constant temperature for 1 hour under the condition of electromagnetic stirring to obtain a yellow silver-containing Hydrosol of rice gold particles. Centrifuge the initial product obtained from the above reaction, discard the supernatant, wash the precipitate with acetone and deionized water 2-3 times, and then dry the precipitate under vacuum for 12 hours at 40°C. The nano-silver particles with surfactant sodium oleate as encapsulating agent are obtained. The obtained silver nanoparticles can be preferably dispersed in non-polar media such as toluene and chloroform, and can also be preferably dispersed in polar media such as water and ethanol. The results of ultraviolet-visible spectrum measurement show that silver nanoparticles in the above non-polar and polar dispersion systems can produce obvio...

Embodiment 2

[0021] Add 61mg of sodium oleate, 17mg of silver nitrate, and 20ml of toluene into a 250ml three-necked reaction flask. After the temperature is slowly raised to 90°C, react at a constant temperature for 1 hour under the condition of electromagnetic stirring to obtain a yellow silver-containing Hydrosol of rice gold particles. Centrifuge the initial product obtained from the above reaction, discard the supernatant, wash the precipitate with acetone and deionized water 2-3 times, and then dry the precipitate under vacuum for 12 hours at 40°C. The nano-silver particles with surfactant sodium oleate as encapsulating agent are obtained. The obtained silver nanoparticles can be preferably dispersed in non-polar media such as toluene and chloroform, and can also be preferably dispersed in polar media such as water and ethanol. The results of ultraviolet-visible spectrum measurement show that silver nanoparticles in the above non-polar and polar dispersion systems can produce obviou...

Embodiment 3

[0023] Add 31mg of sodium linoleate, 10mg of silver perchlorate, and 20ml of xylene into a 250ml three-necked reaction flask. After the temperature is slowly raised to 120°C, react at a constant temperature for 2 hours under the condition of electromagnetic stirring to obtain A yellow hydrosol containing silver, rice and gold particles. Centrifuge the initial product obtained from the above reaction, discard the supernatant, wash the precipitate with acetone and deionized water 2-3 times, and then dry the precipitate under vacuum for 12 hours at 40°C. The nano-silver particles with surfactant sodium oleate as encapsulating agent are obtained. The obtained silver nanoparticles can be preferably dispersed in non-polar media such as toluene and chloroform, and can also be preferably dispersed in polar media such as water and ethanol. The results of ultraviolet-visible spectrum measurement show that silver nanoparticles in the above non-polar and polar dispersion systems can prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com