Making method for NAND-type quick flash memory selective bar

A manufacturing method and selection gate technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of photoresist residue or peeling, incomplete transfer of selection gate patterns, inability to manufacture non-type flash memory, etc. problem, to achieve the effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

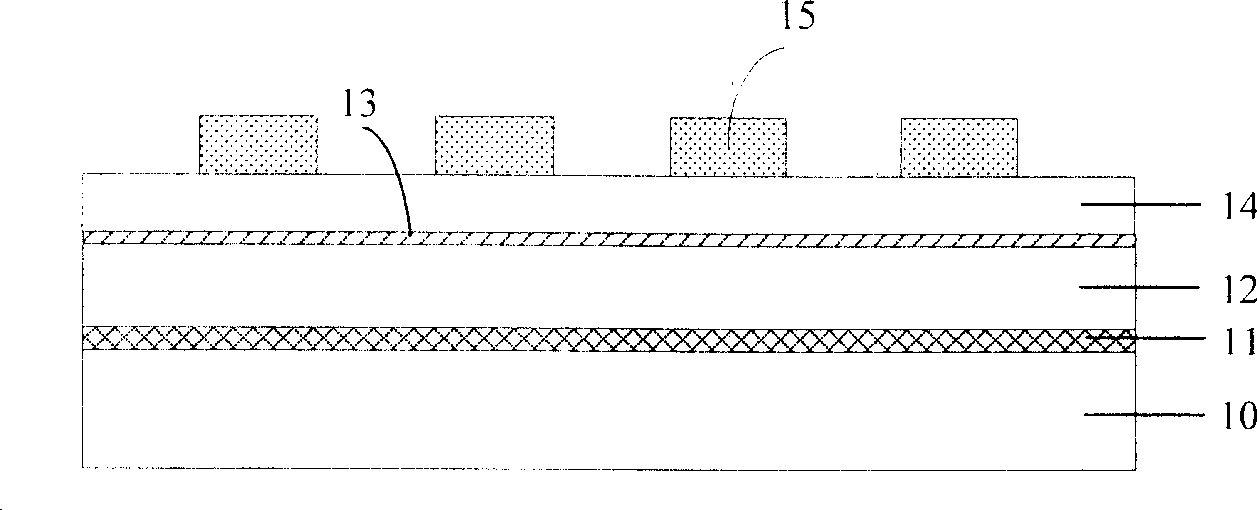

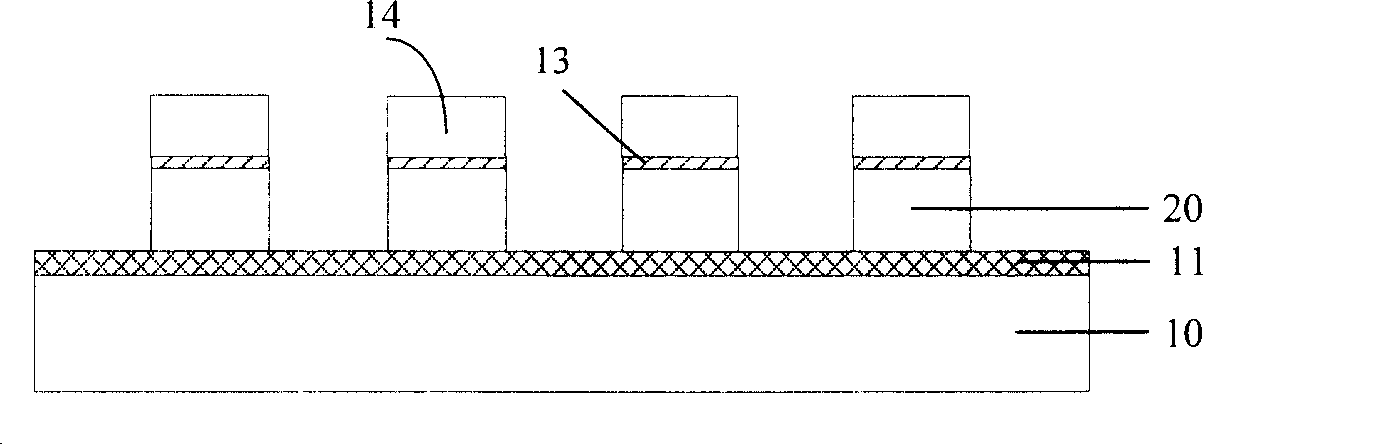

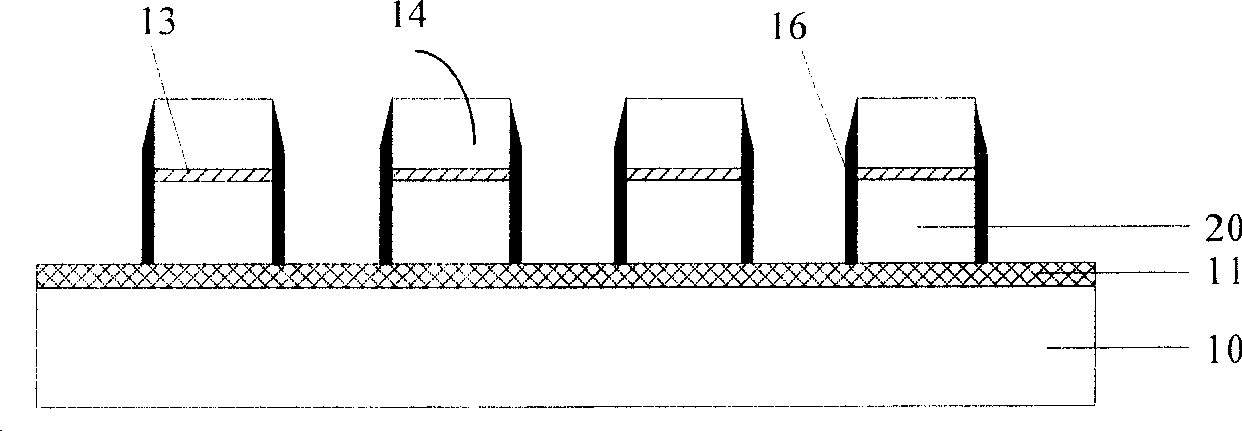

[0027] Because in the existing manufacturing process of non-type flash memory, when defining the position of the selection gate on the photoresist, the photoresist is deposited into the trench between each semiconductor device, because the critical dimension of the semiconductor device is getting smaller and smaller, Then the trenches between the semiconductors will be smaller, and it is difficult for the light to irradiate completely vertically during photolithography, and it is easy to generate diffuse reflection on the surface of the photoresist. The invention directly coats a layer of photoresist on the flat surface of the polysilicon conductive layer instead of depositing photoresist in the grooves between semiconductor devices. In this way, the exposed area increases, the light will not change the transmission direction because the illuminated area is too small, and there will be no diffuse reflection on the surface of the photoresist, so there will be no exposure energy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com