Plane reflection type compound eye cold light source exposure system

An exposure system and plane reflection technology, which is applied in the field of plane reflection compound eye cold light source exposure system, can solve the problems of poor exposure uniformity and low light energy utilization rate, achieve the effect of expanding the exposure area and improving the diffraction effect of lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

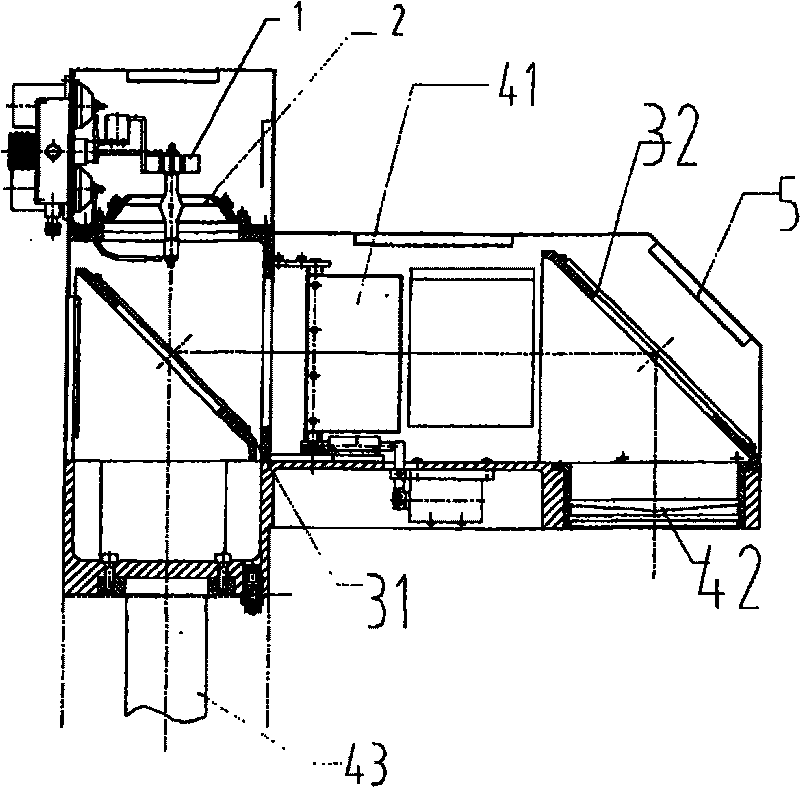

[0039] Such as figure 1 As shown, the flat reflective compound eye cold light source exposure system of this embodiment includes: a light source group 1, a polygonal mirror group device 2, a mirror group, an exposure device, and a casing 5, and the center of the light source of the light source group 1 is placed on the polygonal mirror The central point of the group device 2, the mirror group and the exposure device are placed in the casing 5;

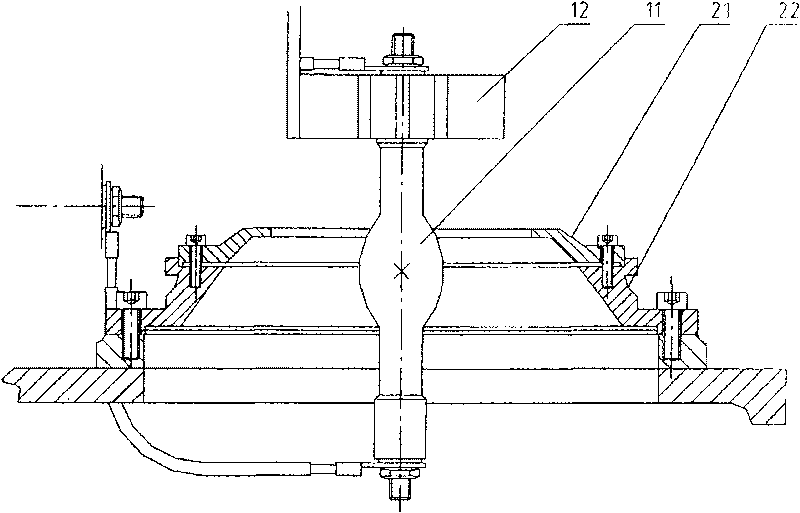

[0040] Such as figure 2 As shown, the lamp source group 1 includes an ultra-high pressure mercury lamp 11 and an ultra-high pressure mercury lamp frame 12, and the ultra-high pressure mercury lamp 11 is fixed on the ultra-high pressure mercury lamp frame 12;

[0041] The multi-faceted mirror group device 2 includes an upper mirror base 21 and a lower mirror base 22, the upper mirror base 21 is closely stacked on the lower mirror base 22,

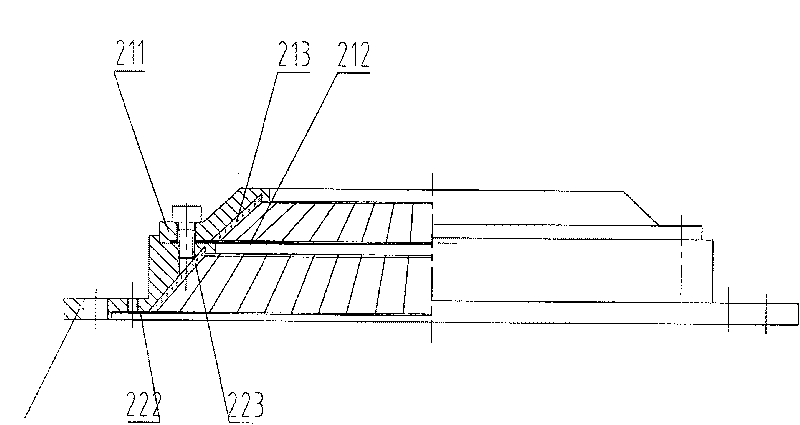

[0042] Such as image 3 As shown, the upper lens holder 21 includes an upper plate 211, an up...

Embodiment 2

[0066] The lithography machine of this embodiment mainly includes an exposure light source, a microscope for separating the field of view, a precision workbench, a mechanism for conveying silicon wafers, and a PLC controller. exposure system.

[0067] The distance between the working exposure surface (that is, the position of the mask and the silicon wafer) and the top of the collimating mirror is 100mm.

[0068] When exposing (that is, during photolithography), 64 point light sources work at the same time, irradiating the mask and the silicon wafer at different angles at the same time, and the obtained diffraction pattern is uniform.

[0069] The planar reflective compound eye cold light source exposure system has been successfully applied in the lithography machine, and the exposure energy has reached 18mw / cm 2 , and successfully developed a separate field of view microscope, the maximum split viewing distance reached 100mm.

[0070] Compared with the prior art, this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com