Combustion nozzle of gasification stove of using pressed dry coal powder

A technology for pressurized gasification and combustion of nozzles, which is applied to burners, burners, combustion types and other directions of burning powder fuel, can solve problems such as restricting the service life of the burner, increasing processing difficulty, and wear of the pipe wall at the outlet, etc. To achieve excellent cooling function, the effect of low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

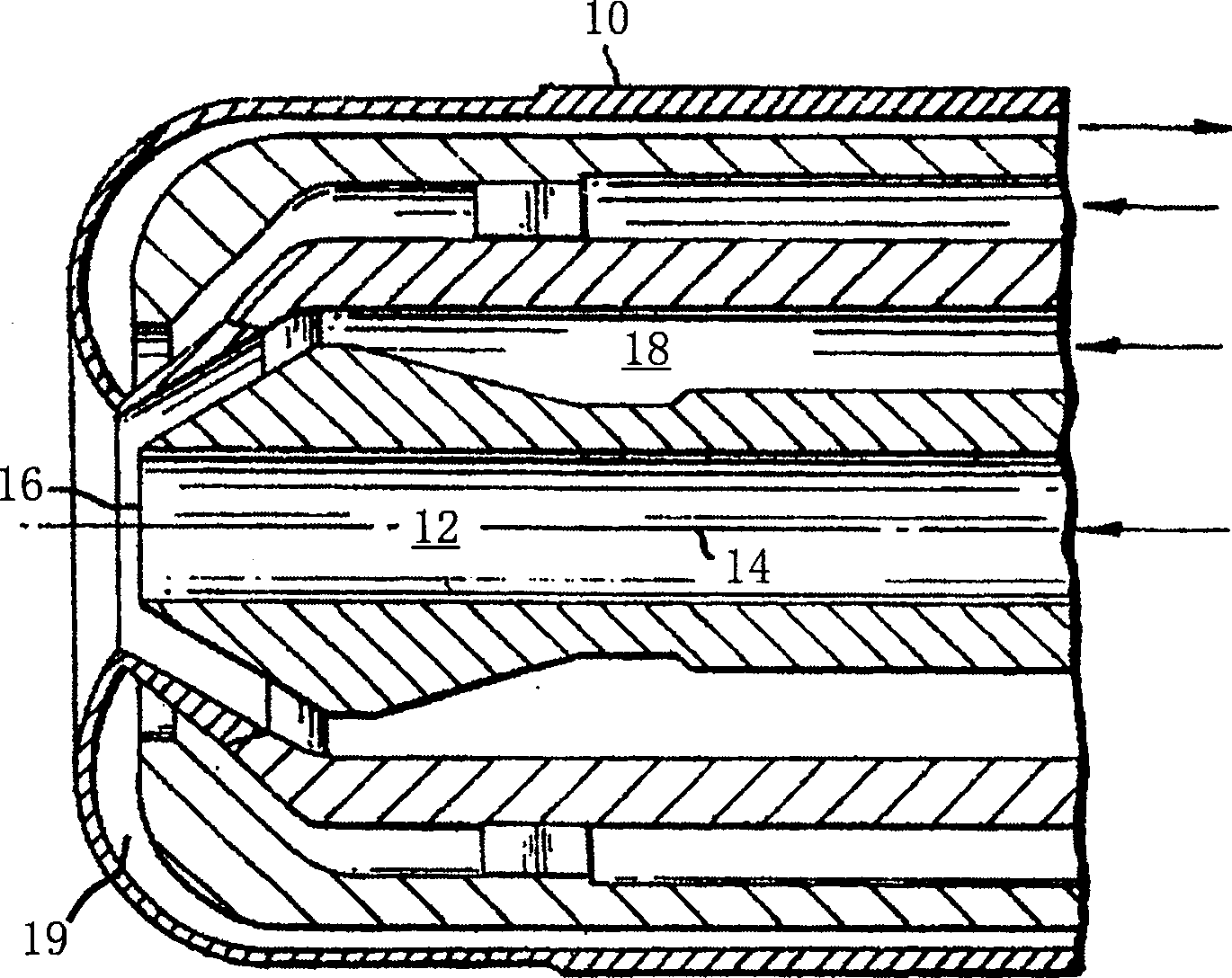

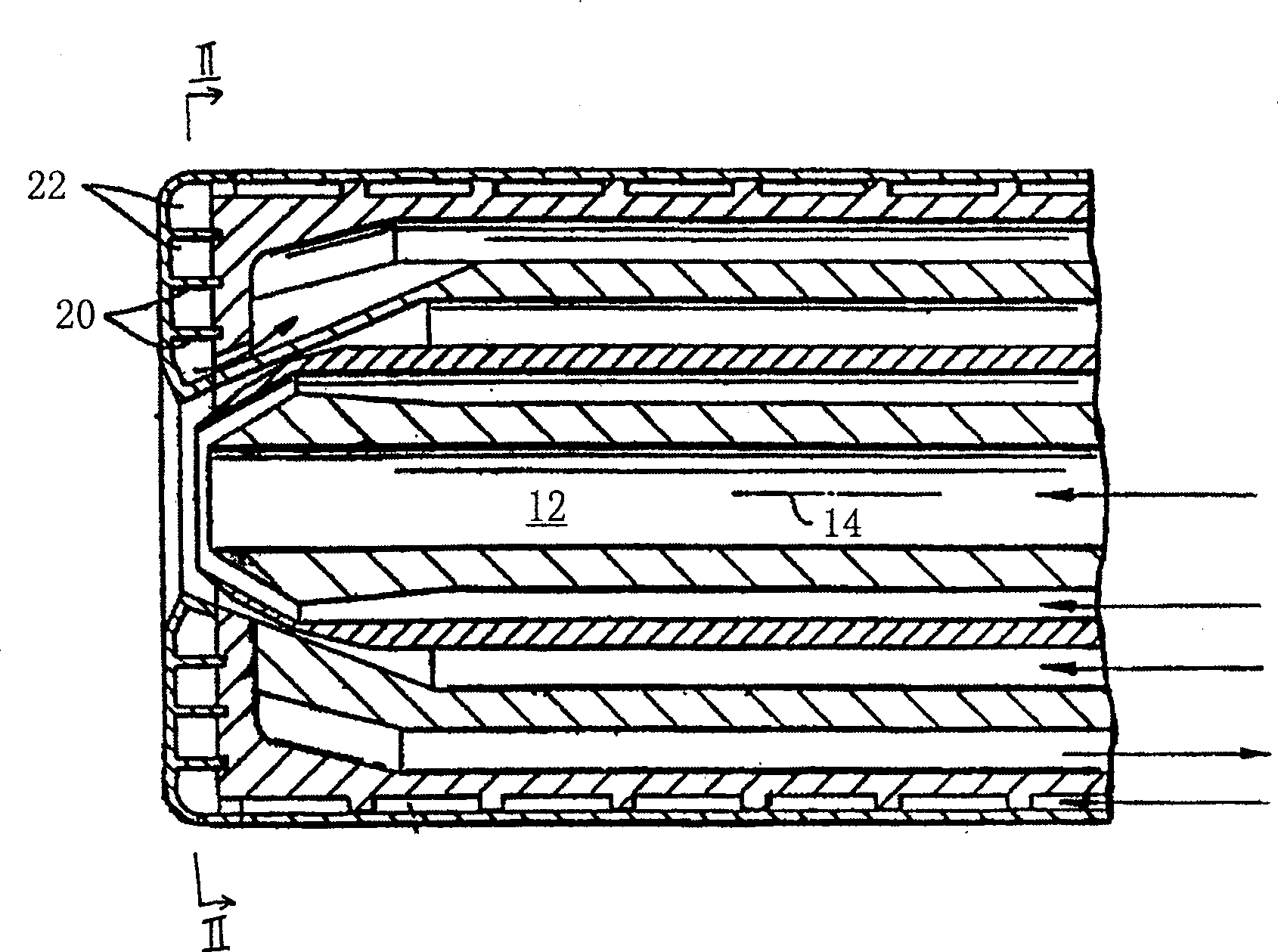

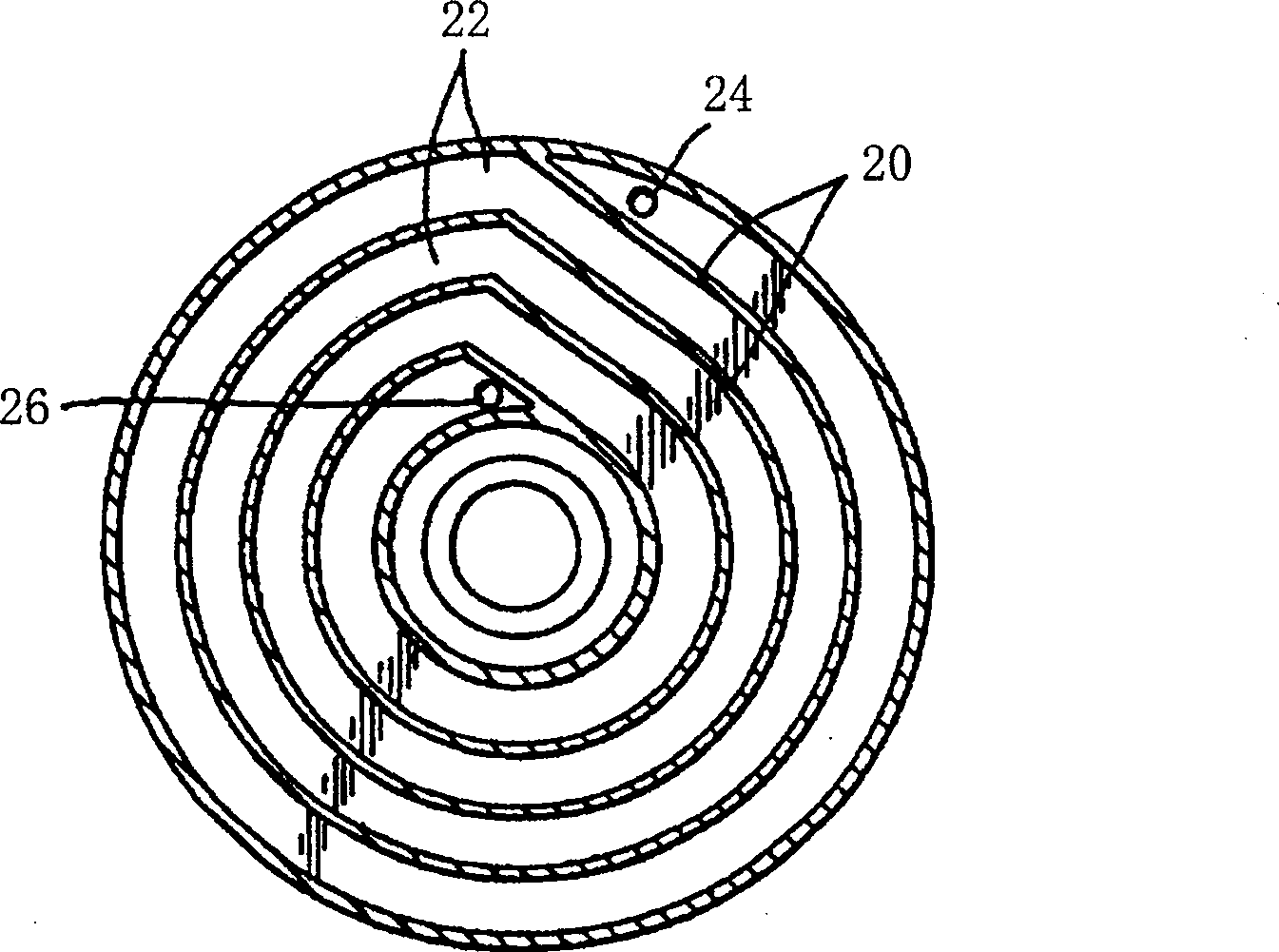

[0021] image 3 It is a schematic diagram of the internal structure of the combustion nozzle of the dry pulverized coal pressurized gasifier of the present invention. see image 3 As shown, the combustion nozzle 30 of the dry pulverized coal pressurized gasifier of the present invention includes a central passage 34 and an outlet 35 arranged along the longitudinal axis 32 of the nozzle, which are used to transport pulverized coal into the gasifier, and a center passage around the center The channel 34 and the annular channel 36 coaxially arranged therewith and the gas supply port 37 are used for delivering oxygen-containing gas into the gasifier, and a cooling channel 38 arranged on the periphery of the annular channel 36 is used for circulating coolant. The combustion nozzle 30 has a front end surface 31 at the discharge end, and the outlet 35 of the central channel 34 is arranged at the center of the front end surface 31, and the pulverized coal is sent into the furnace fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com