Half-direct-driven wind power transmission system

A transmission system, semi-direct drive technology, applied in the field of transmission system, can solve the problems of poor installation alignment between generator and gearbox, large space occupation, high failure rate, etc., to reduce the load on the machine head, reduce the space occupied, and reduce the service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

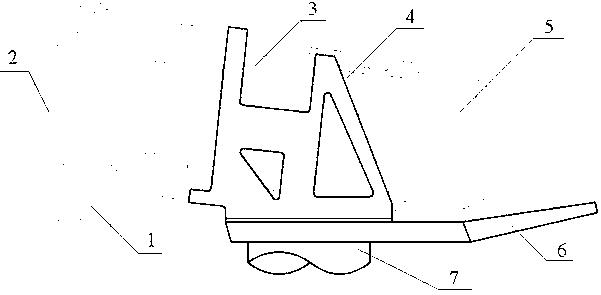

[0021] Such as figure 1 As shown, the whole machine is mainly divided into 3 large modules, hub rotor assembly module 3, gear box assembly module 4 and generator assembly module 5. Other structures also include blade 1, hub 2, nacelle base 6 and tower 7. The hub 2 is connected to the blade 1 by bolts, and the energy acting on the blade 1 is transferred to the hub 2. Inside the hub rotor assembly module 3, the hub 2 is connected to the main shaft by bolts; the generator module 5 is directly assembled in the gear box assembly On the module 4, the gear box is fixed on the base 6 of the nacelle. The gearbox assembly module 4 and the generator assembly module 5 are installed integrally, the output end of the gearbox assembly module 4 is connected to the input end of the generator assembly module 5, the output end of the gearbox assembly module 4 and the input end of the generator assembly module 5 are on the same axis, After the gearbox assembly module 4 and the generator assembly m...

Embodiment 2

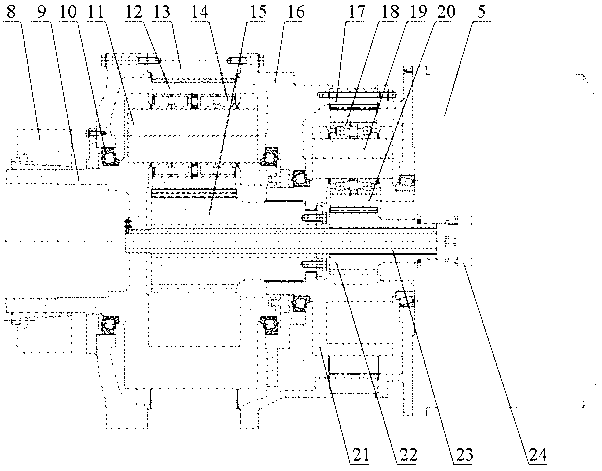

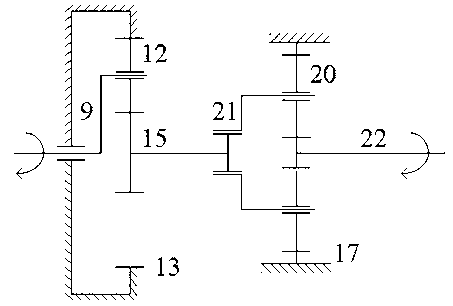

[0023] Such as figure 2 As shown, the speed increaser adopts a two-stage NGW planetary gear system, and the main shaft is connected to the first-stage planet carrier 9 inside the gear box through the locking disk 8, and then transmits energy to the first-stage planet carrier 9; 9 As the input of the speed increaser, it is supported on the box 16 through the tapered roller bearing 10. The planet carrier and the planetary gear shaft are interference fit, so the energy is transmitted to the first-stage planetary gear shaft 11; The first-stage planetary gear 12 is supported on the first-stage planetary gear shaft 11 through a double-row cylindrical roller bearing 14 and meshes with the first-stage inner ring gear 13, which is fixed on the box 16 by screws , Under the action of the first-stage planetary gear shaft 11, the rotation and revolution of the first-stage planetary gear 12 are realized; the first-stage planetary gear 12 is externally meshed with the first-stage sun gear sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com