Electric generating set small side road system and control method thereof

The technology of a generator set and control method is applied in the direction of engine components, engine starting, machine/engine, etc., which can solve the problems of decreased sealing of valve core and valve body, waste of valve core, waste of electricity and time for fuel plants, etc. To achieve the effect of shortening the start-up time, good sealing effect and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

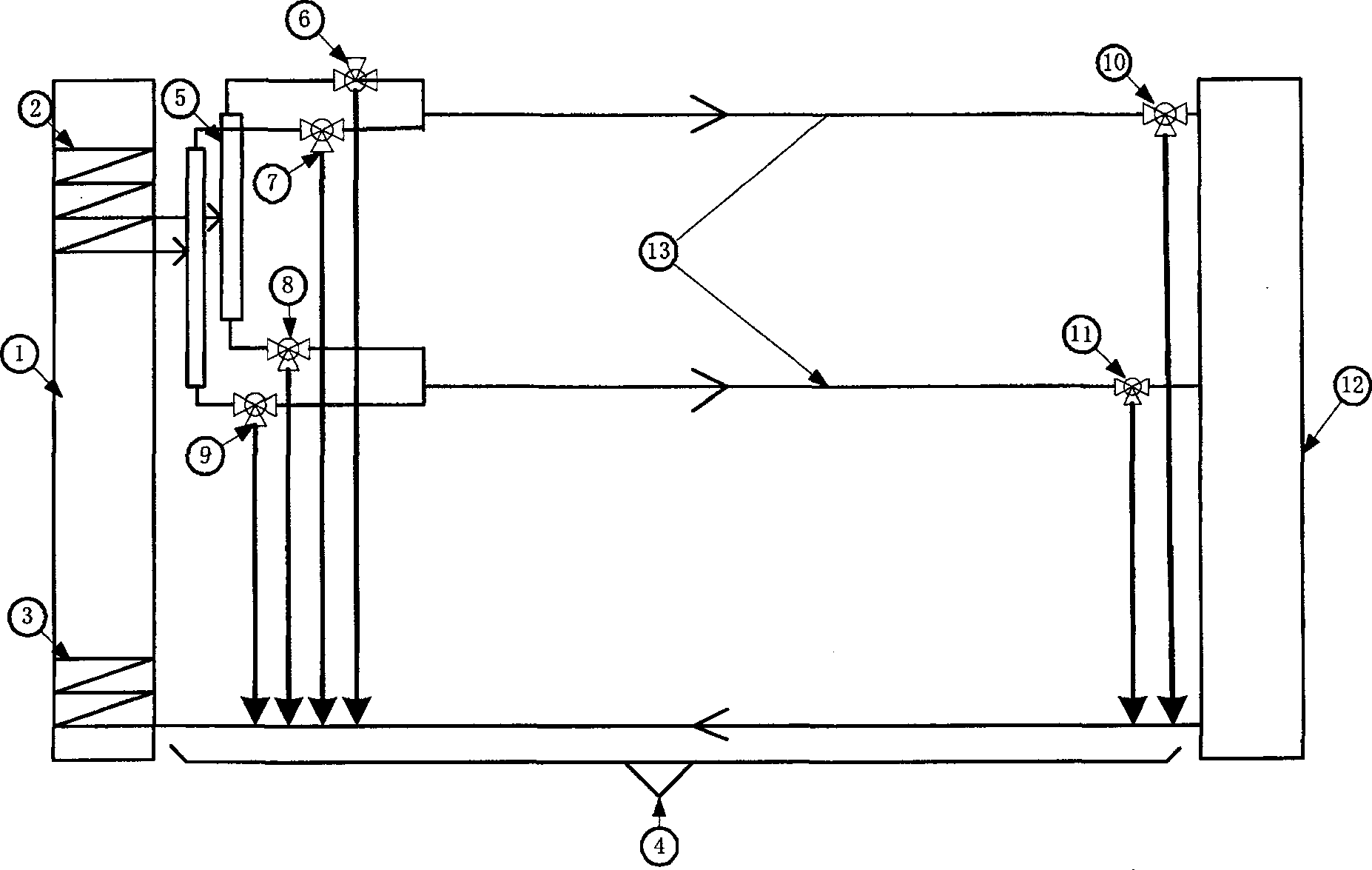

[0028] figure 1 It is a schematic diagram of the installation of the unit adopting the small bypass system of the present invention. The thermoelectric unit includes at least two main engines: the steam turbine 12, the boiler 1 and the piping system, and the bypass system is the main component for regulating and coordinating the two main engines. During the operation of the unit, the steam from the boiler 1 enters the superheater outlet header 5 through the superheater 2, and then enters the high-pressure cylinder (not shown in the figure) of the steam turbine 12 through the main steam pipeline 13 through the steam turbine 12 to do work and exhaust steam. After passing through the cold section 4, it enters the reheater 3 in the boiler. The large bypass is located between the boiler outlet header 5 and the reheater cold section 4. In this embodiment, the large bypass includes large bypass valves 6, 7, 8, 9 and the communication pipeline connected with the cold section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com