Compound processing machinery

A composite processing and composite tool technology, applied in metal processing machinery parts, metal processing, metal processing equipment and other directions, can solve the problems of low sub-processing efficiency, achieve the effect of easy management and avoid interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

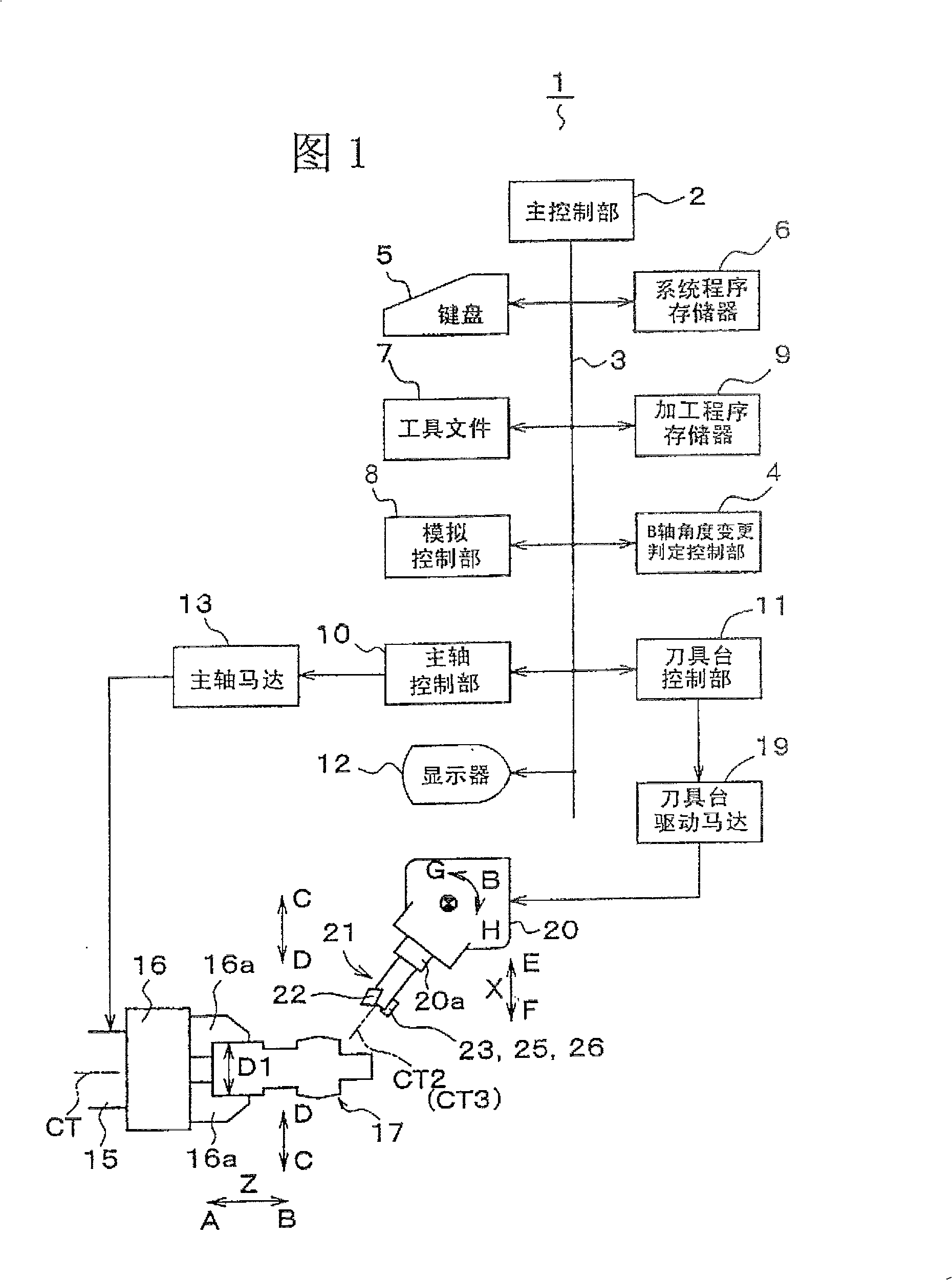

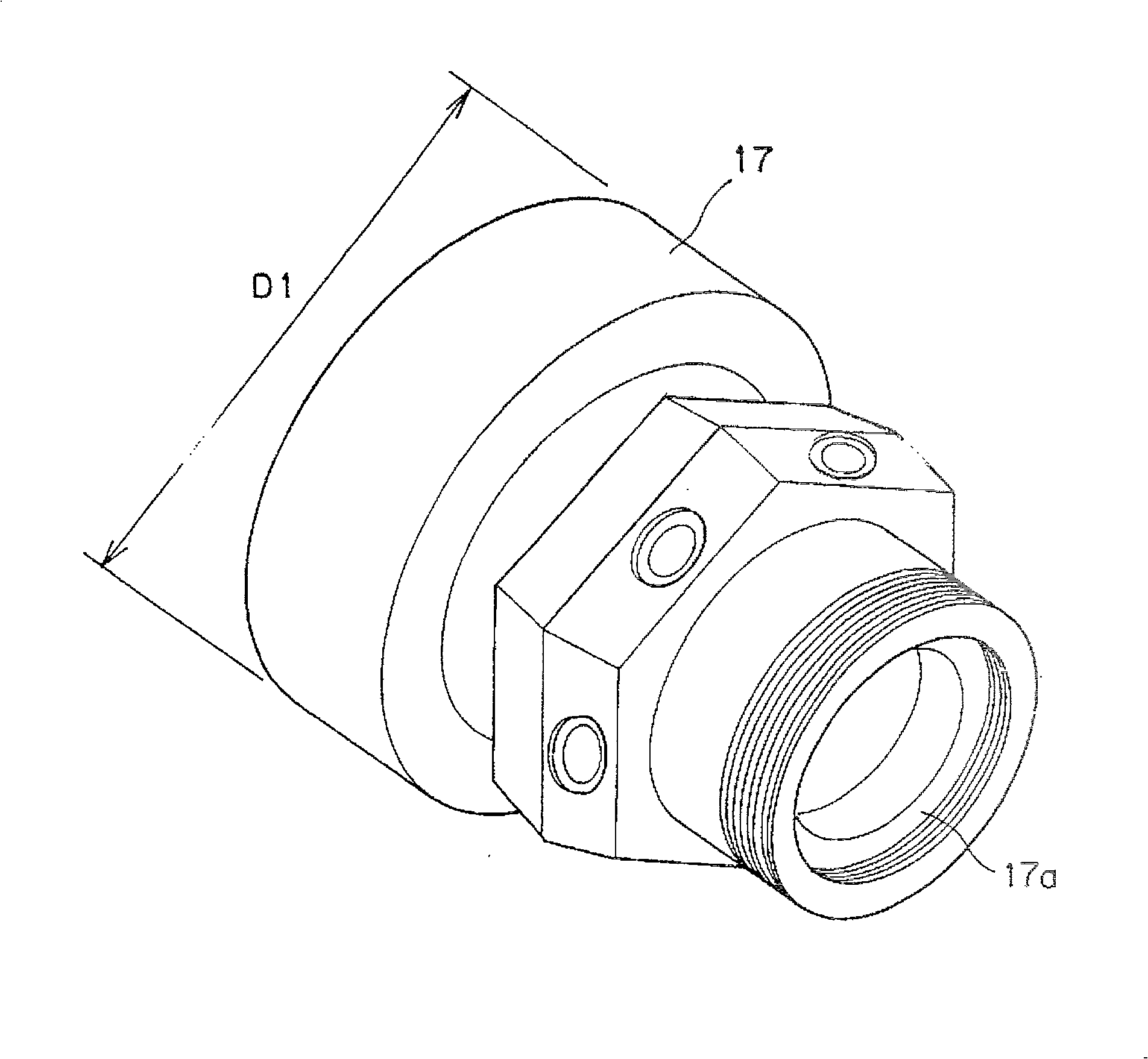

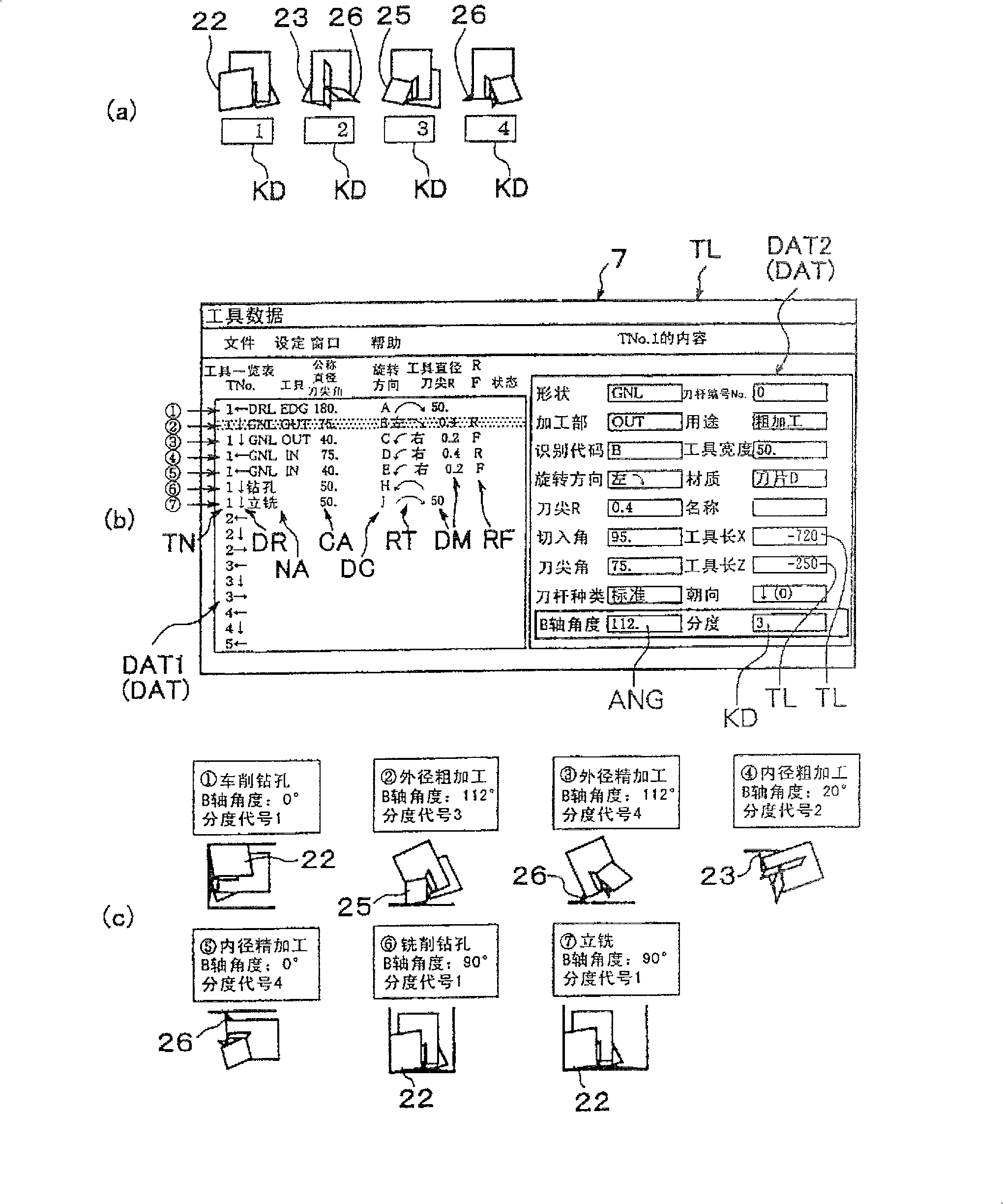

[0031] As shown in Figure 1, a compound processing machine (machine tool) 1 is provided with a main control unit 2, and the main control unit 2 is provided with input units such as a bus 3 and a keyboard 5, a system program memory 6, a tool file 7, a simulation control unit 8, and a processing program. The memory 9, the B-axis angle change determination control unit 4, the spindle control unit 10, the tool post control unit 11, and the display 12 are connected. The spindle motor 13 is connected to the spindle control unit 10 . Centering on the axis CT parallel to the Z-axis, the freely rotatable, drive-positioned spindle 15 is connected to the spindle motor 13 , and the chuck 16 is arranged on the spindle 15 . Claws 16a are provided on the chuck 16, and the claws 16a can freely grasp or release the workpiece 17 to be processed, and are freely driven to move in the arrow C, D directions.

[0032] The tool rest drive motor 19 (multiple) is connected on the cutter rest control p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com