Solid-state fermentation installation

A solid-state fermentation and fermentation bag technology, applied in solid-phase fermentation bioreactors, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve the problems of high equipment requirements, large space occupation, labor-intensive, etc. The temperature distribution of the material is uneven, the effect of preventing the entry of bacteria and reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

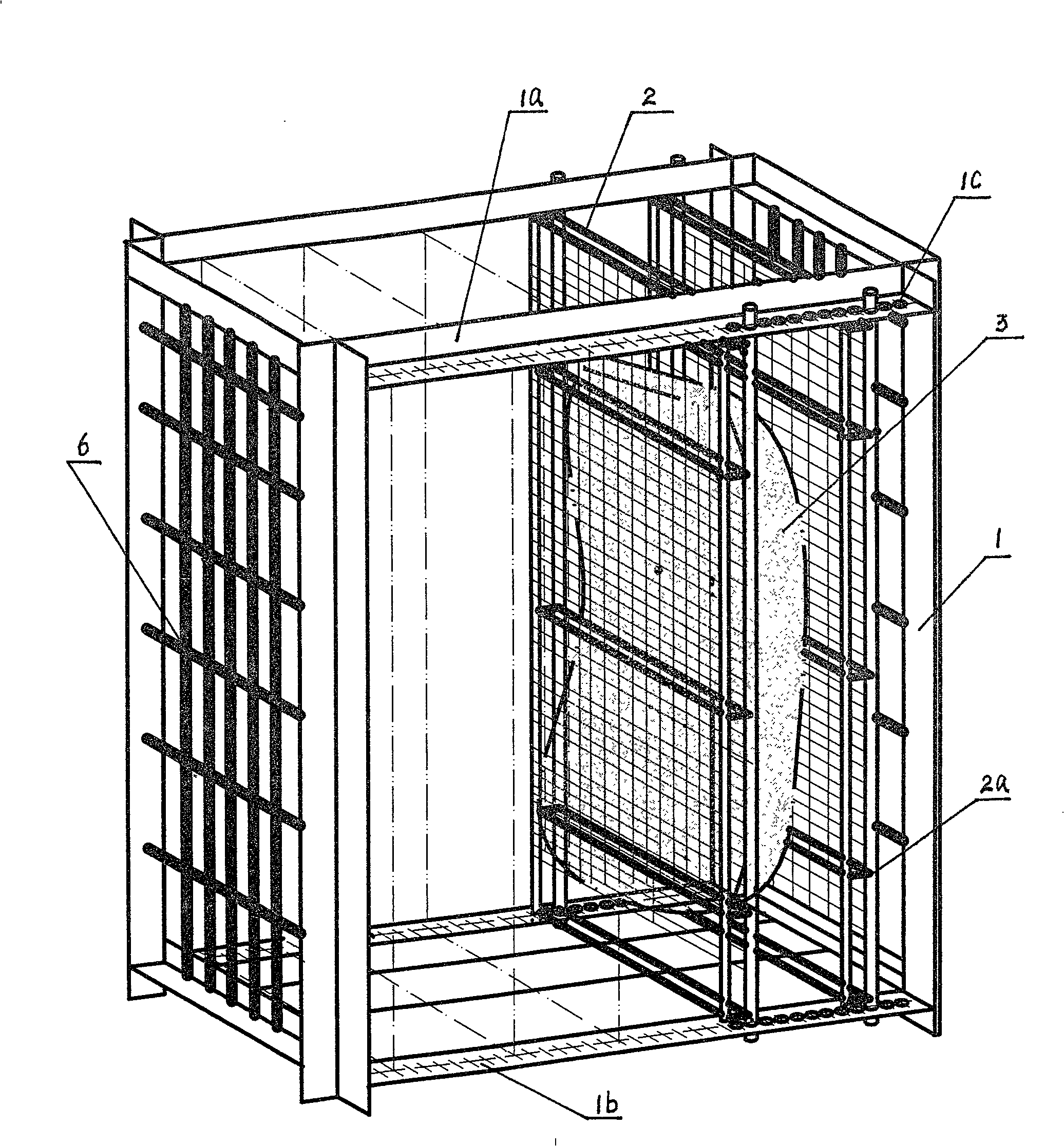

[0020] Embodiment 1: A solid-state fermentation device, characterized in that it comprises a main frame 1 and a fermentation unit inside the main frame 1; the fermentation unit is composed of an aeration plate 2 and a material fermentation bag 3 arranged between the aeration plate 2.

[0021] It can also be seen from the figure that the aeration plate 2 of the fermentation unit used in this example is a double-layer mesh frame; reinforcing ribs 2a are arranged between the layers of the double-layer mesh frame.

[0022] The upper beam 1a and the lower beam 1b of the main frame 1 are provided with mounting holes 1c correspondingly, and the mesh frame of the fermentation unit has fixed posts extending from the top and bottom to the mounting holes 1c for fixing.

[0023] The material fermentation bag 3 in this example is a microporous air-permeable bag, and the diameter of the micropores is between 0.01 and 5.0 μm.

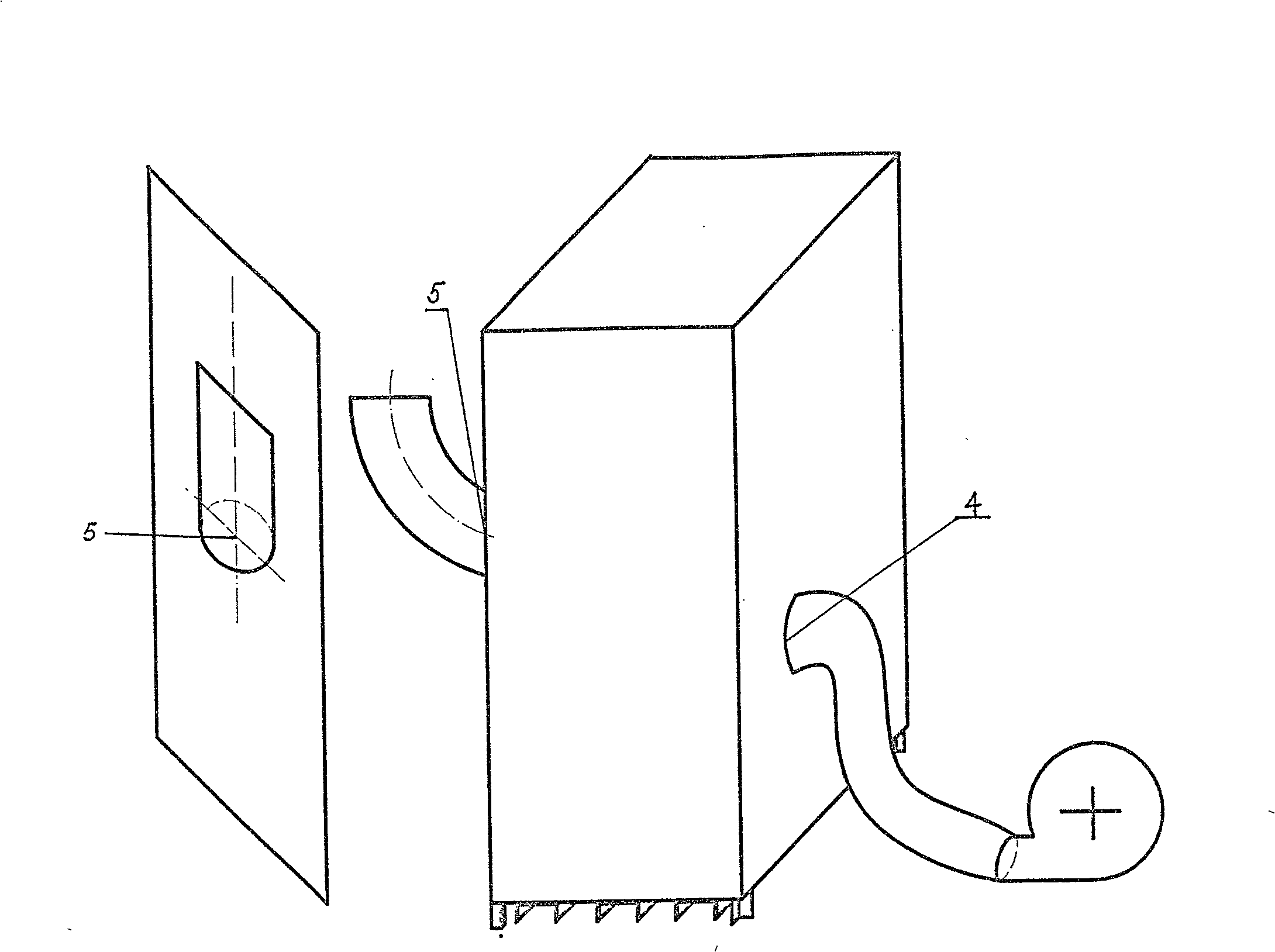

[0024] Combine figure 1 with figure 2 , The main frame 1 of the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com