Vibroflot equipment wireless automatic logging system

An automatic recording and vibrator technology, applied in signal transmission systems, instruments, etc., can solve the problems of difficult wiring, inconvenient movement, and high labor costs, so as to improve work efficiency and project quality, avoid inconvenient equipment movement, and avoid wiring difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with examples with reference to the accompanying drawings.

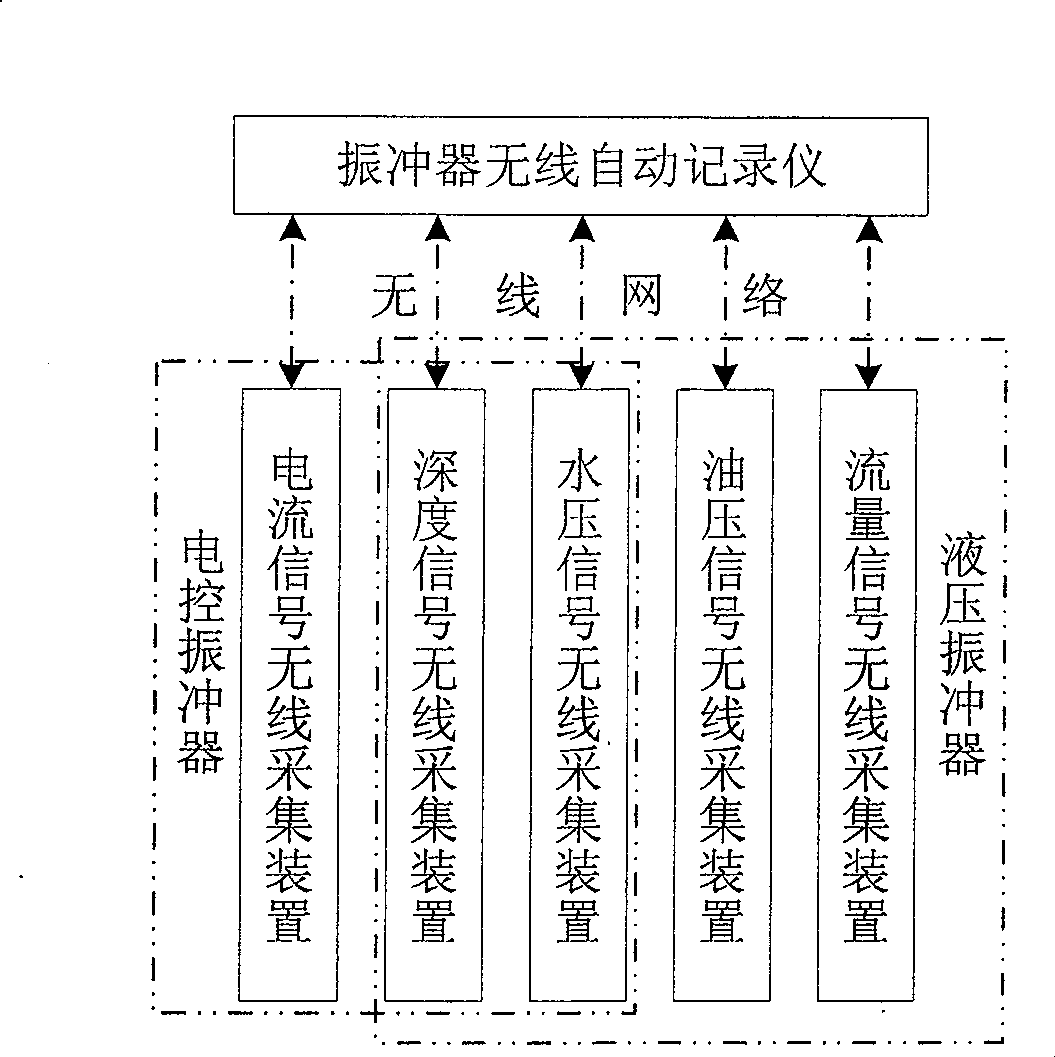

[0026] The vibrator wireless automatic recording system is composed of a sensor wireless acquisition device and a vibrator wireless automatic recorder. It uses wireless network communication to form a wireless star network with the automatic recorder as the center and the sensor wireless acquisition device as the terminal. The network consists of structured as figure 1 shown.

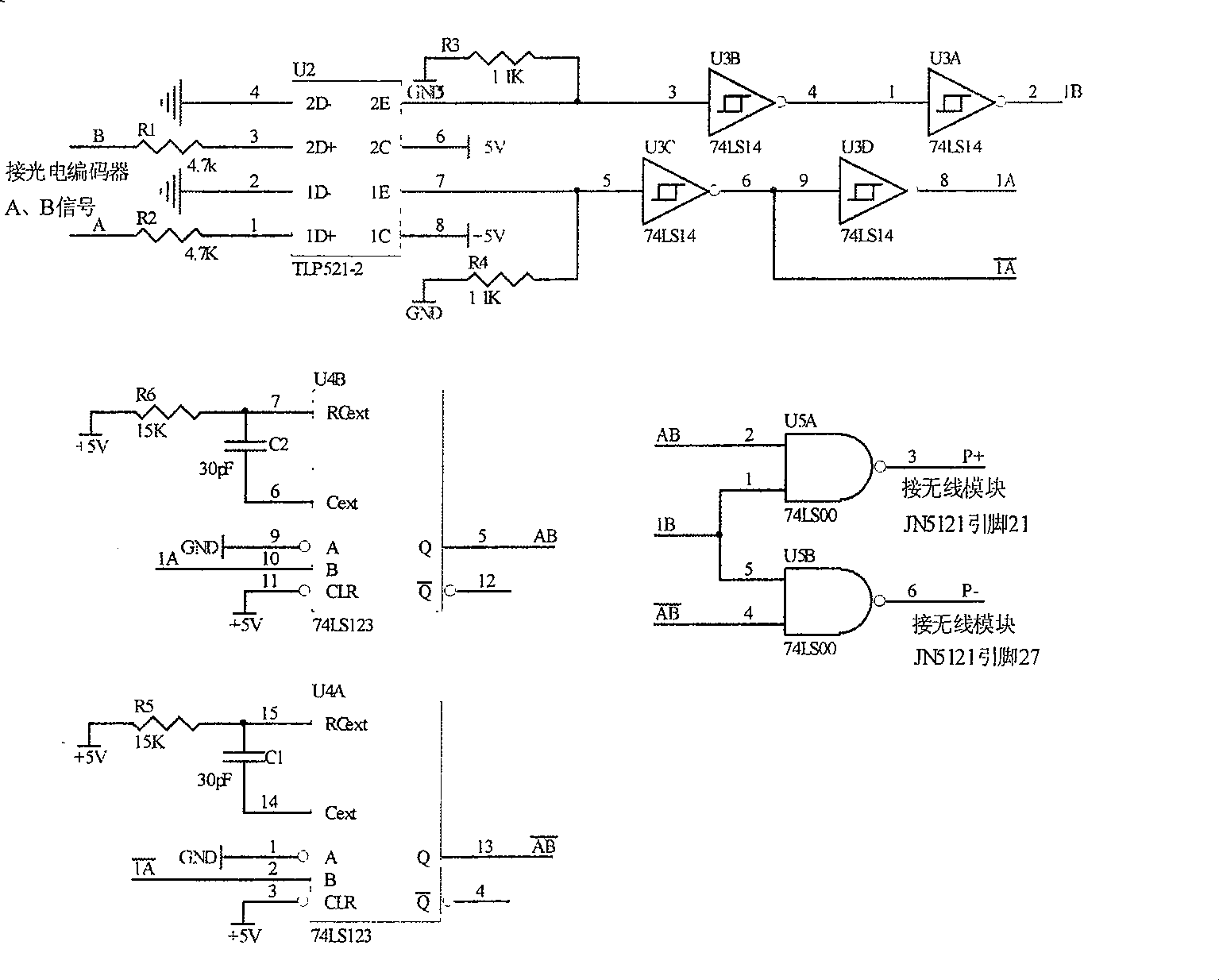

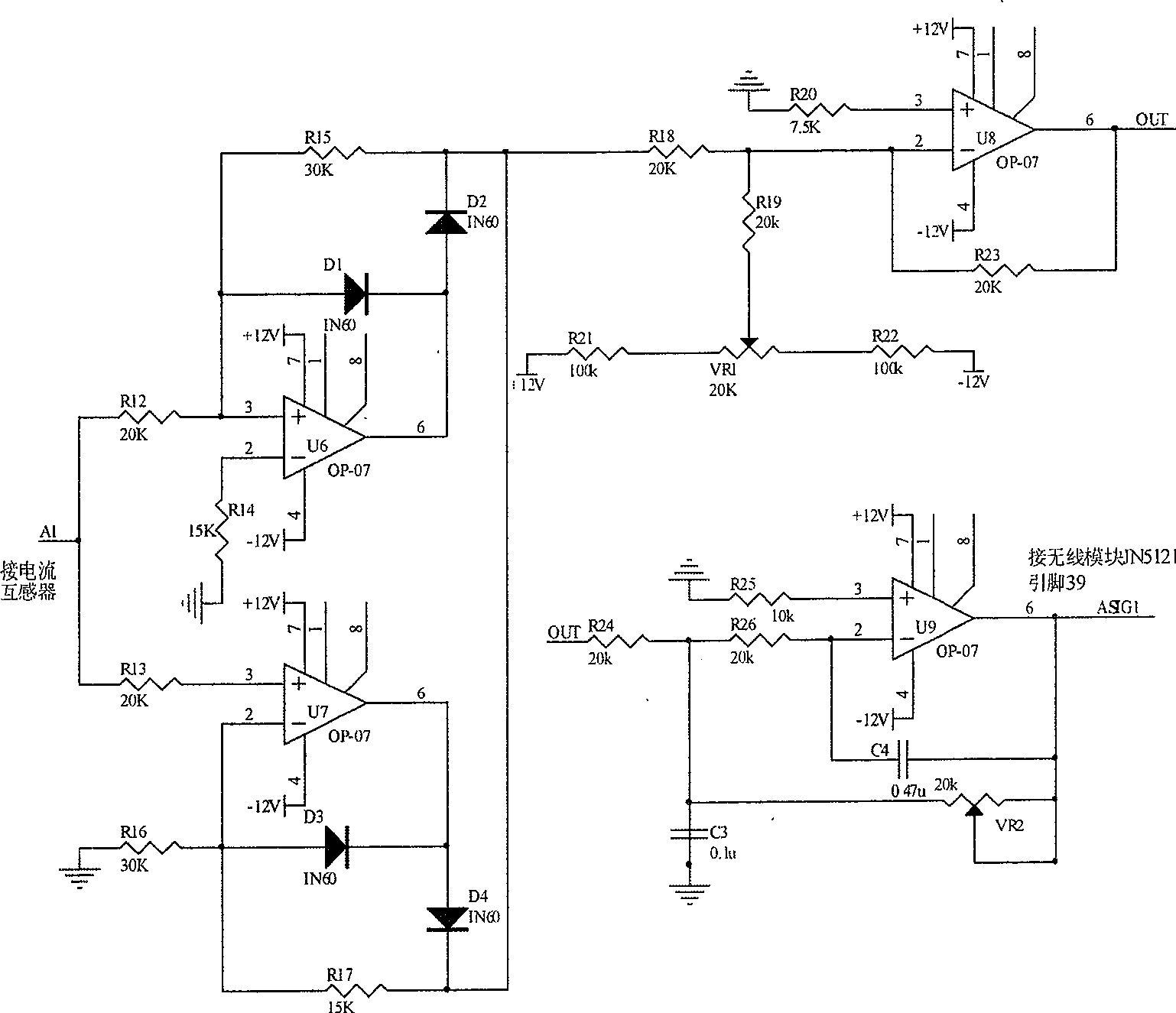

[0027] The sensor wireless acquisition device is composed of sensors, signal conditioning circuits, wireless modules and power supplies. It is suitable for electric control and hydraulic vibrators, and can realize the acquisition of signals such as depth, current, flow, oil pressure, and water pressure. The vibrator needs to collect depth, oil pressure, flow and water pressure sensor signals, and the electric control vibrator needs to collect depth, current and water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com