Method for preparing biologic diesel oil from seeds of Mono Maple

A technology for biodiesel and ingot maple seeds is applied in the field of preparing biodiesel from ingot maple seeds, which can solve problems such as being in the research stage, and achieve the effects of easy planting, increased economic benefits, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of Yuanbao maple oil:

[0025] Shelling: control the moisture content of the maple seeds within 8-12% (moisture adjustment is the key to ensure the yield), enter the shelling machine dedicated to maple seeds for peeling, and after the treatment, the shells will be separated by winnowing After the kernel is separated, Yuanbao Fengren is obtained.

[0026] Oil extraction: adjust the water content of the shelled and separated Yuanbao maple kernels to control the water content within the range of 8-10%, and use a 90-type oil press to extract the oil, and the oil yield is more than 85%.

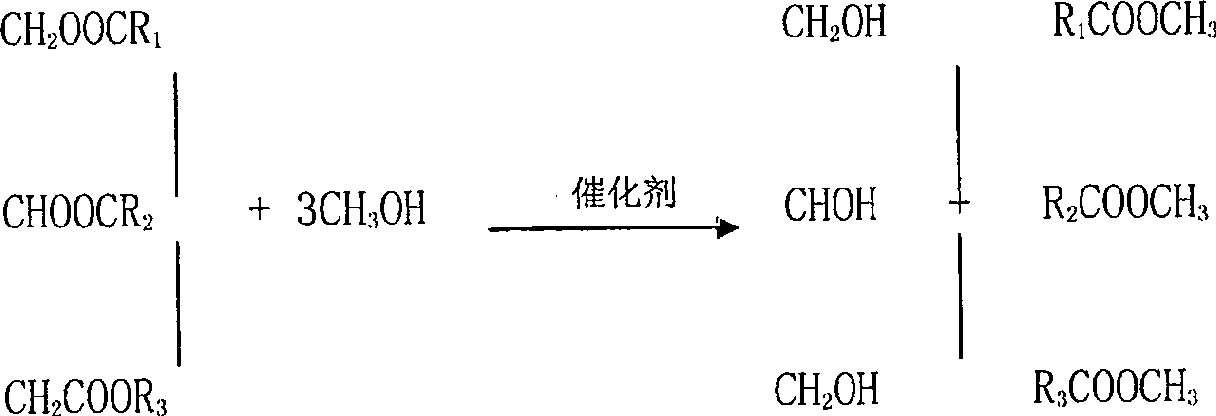

[0027] (2) Transesterification and supplementary esterification: Mix 100 parts of Yuanbao maple oil with 40 parts of anhydrous methanol and 2 parts of sodium hydroxide, and reflux esterification on a constant temperature water bath at 70 ° C. The stirring speed is about 60 rpm, and the reaction time is After 2 hours, add 6 parts of concentrated sulfuric acid and continue to...

Embodiment 2

[0032] (1) Preparation of Ingot Maple Oil: Same as Example 1.

[0033] (2) Transesterification and supplementary esterification: Mix 100 parts of Yuanbao maple oil with 35 parts of anhydrous methanol and 2 parts of potassium hydroxide, and reflux esterification on a constant temperature water bath at 75 ° C. The stirring speed is about 60 rpm, and the reaction time is After 2.5 hours, add 5 parts of concentrated sulfuric acid and continue the reaction for 2.5 hours. After the reaction, wash with water to remove by-products.

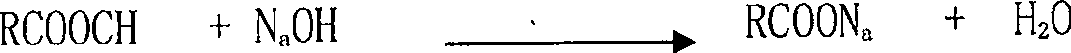

[0034] (3) Alkali refining: Add 0.08% of its weight and a sodium carbonate solution with a content of 5% in the reaction product, after adding at 70°C, quickly heat up to 90°C according to the speed of 1°C / hour, stir while heating, until Incubate at 90°C for 3 hours, the stirring speed is 50 / min in the mixing and heating stage, and 15r / min in the heat preservation stage, let the soap grains separate completely for precipitation, wash with warm water sever...

Embodiment 3

[0038] (1) Preparation of Ingot Maple Oil: Same as Example 1.

[0039] (2) Transesterification and supplementary esterification: Mix 100 parts of Yuanbao maple oil with 40 parts of anhydrous methanol and 1.5 parts of sodium hydroxide, and reflux esterification in a constant temperature water bath at 72 °C, with a stirring speed of about 60 rpm and a reaction time of After 2 hours, 5 parts of concentrated sulfuric acid was added, and the reaction was continued for 2.5 hours. After the reaction was completed, by-products were washed with water.

[0040] (3) Alkali refining: add 0.1% of its weight to the reaction product, and a sodium hydroxide solution with a content of 4%, after adding at 70°C, quickly heat up to 90°C at a speed of 1°C / hour, stir while heating, Keep warm at 90°C for 8 hours, the stirring speed is 60r / min in the mixing and heating stage, and 20r / min in the heat preservation stage, let the soap grains separate completely for precipitation, wash with warm water se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com