Fuel pressure controlling device and controlling method for mini combustion turbine

A micro gas turbine, fuel pressure technology, applied in the fuel control of turbine/propulsion device, turbine/propulsion fuel delivery system, charging system, etc., can solve the problem of poor adaptability, time-varying uncertainty, poor tuning, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

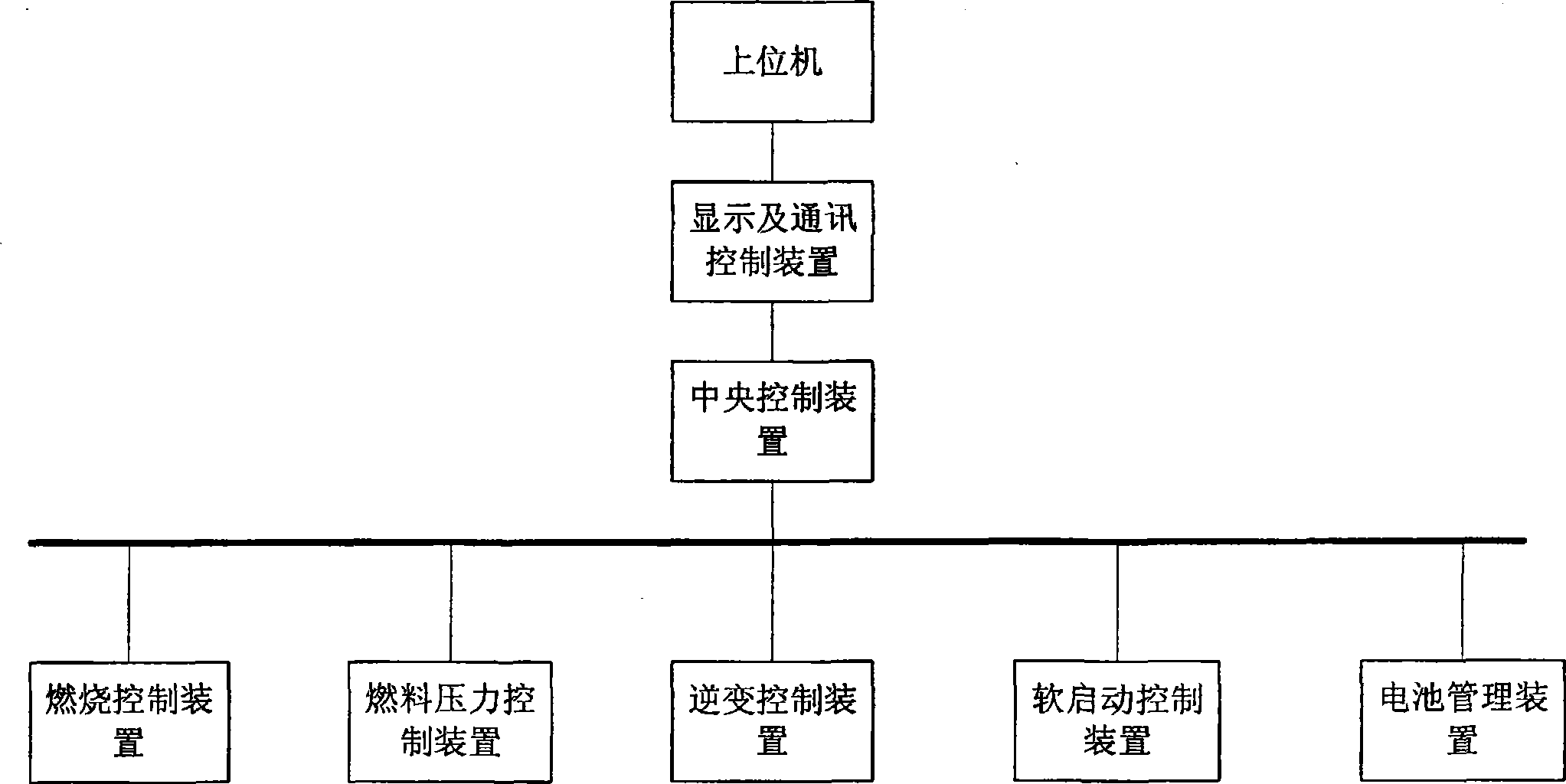

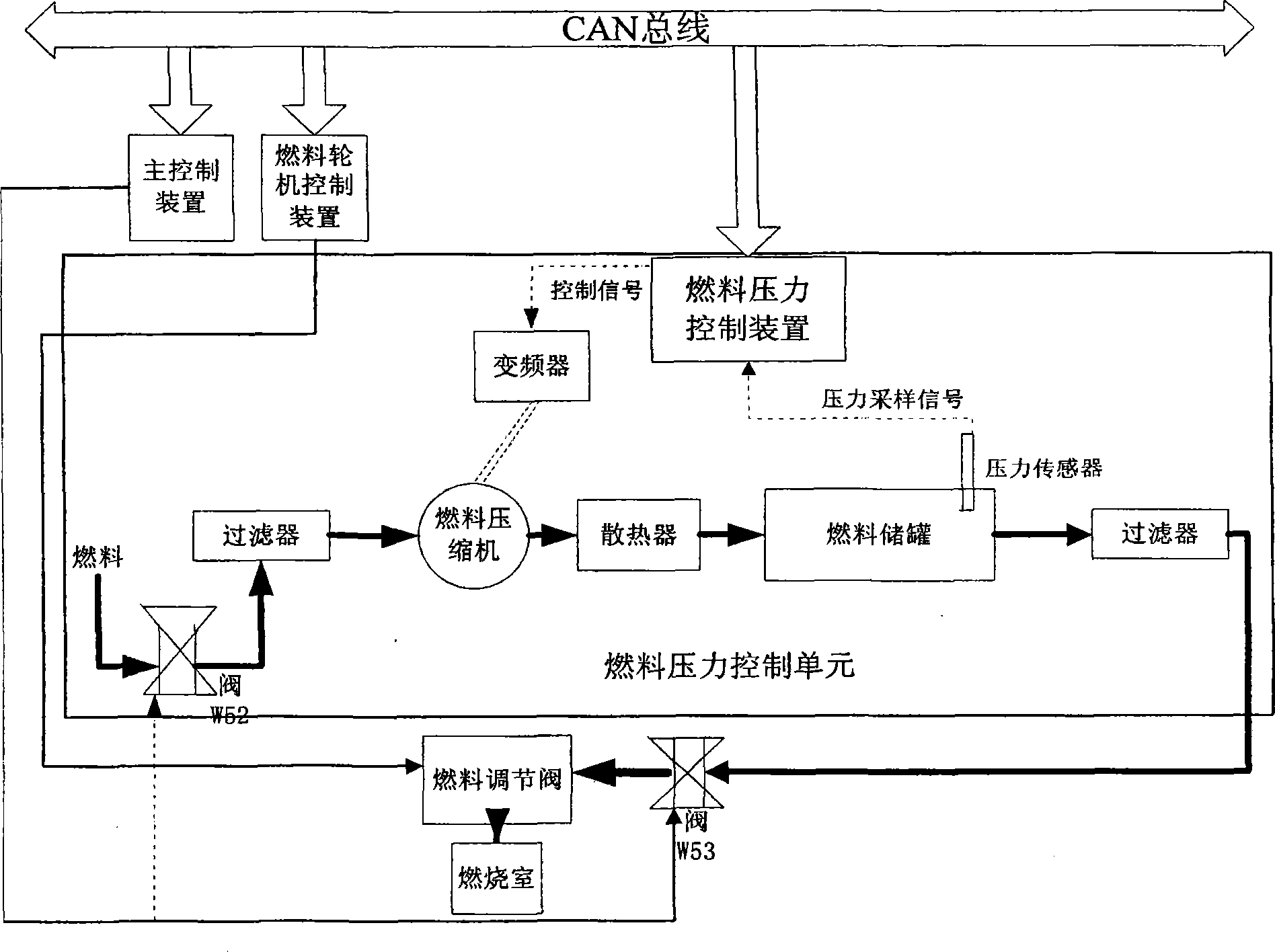

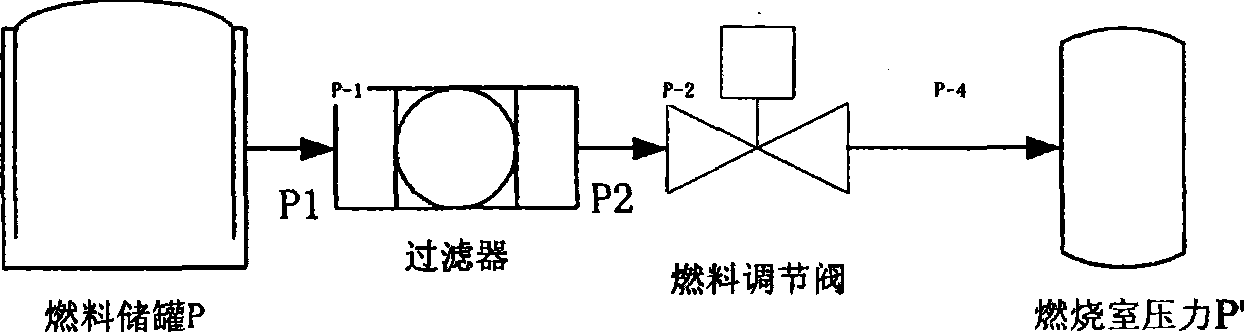

[0096] Below in conjunction with accompanying drawing, the present invention will be further described;

[0097] The present invention is the hardware device of the fuel pressure control device such as Figure 4 As shown, it includes TI's digital signal processor TM320LF2407A and its minimum system design, signal detection circuit, signal processing circuit, communication processing circuit, and drive output circuit; among them, the signal processing circuit, communication processing circuit, and drive power supply circuit are respectively connected with the digital signal The processor is connected; the signal detection circuit is connected with the signal processing circuit, and the communication processing circuit is connected with the central control device;

[0098] The minimum system design mainly includes: external expansion 128K * 16BIT RAM, 128K * 16BIT EPROM, 8K * 16BIT EEPROM, logic control circuit, crystal oscillator circuit, reset circuit.

[0099] Reset circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com