Axial flow threshing separation facility in tangential feeding type

A technology for threshing separation and feeding shafts, which is applied in threshing equipment, applications, agricultural machinery and implements, etc. It can solve the problems of complex structure of clamping and conveying devices, broken stems, high cost, etc., and achieves simple structure and high cleaning rate , evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

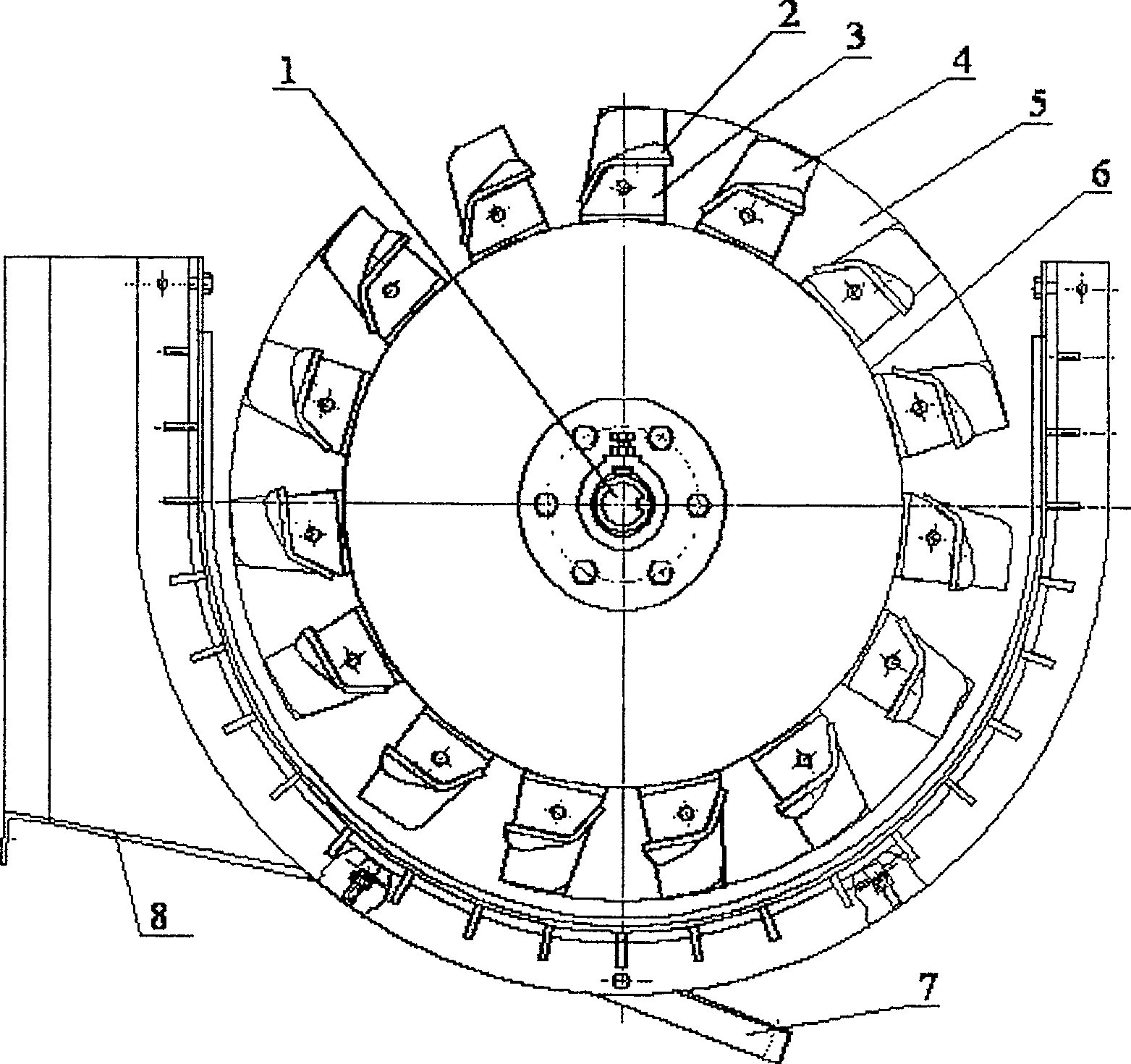

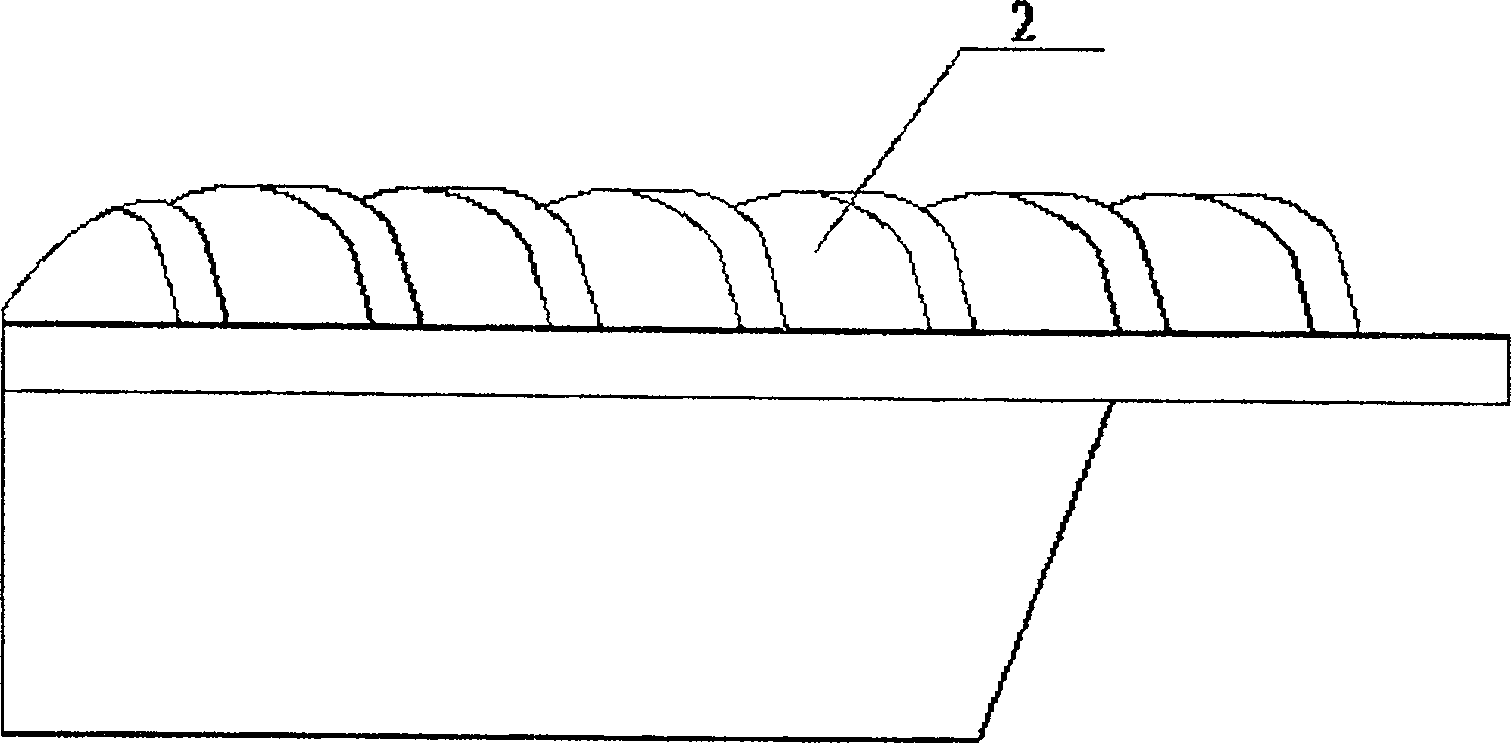

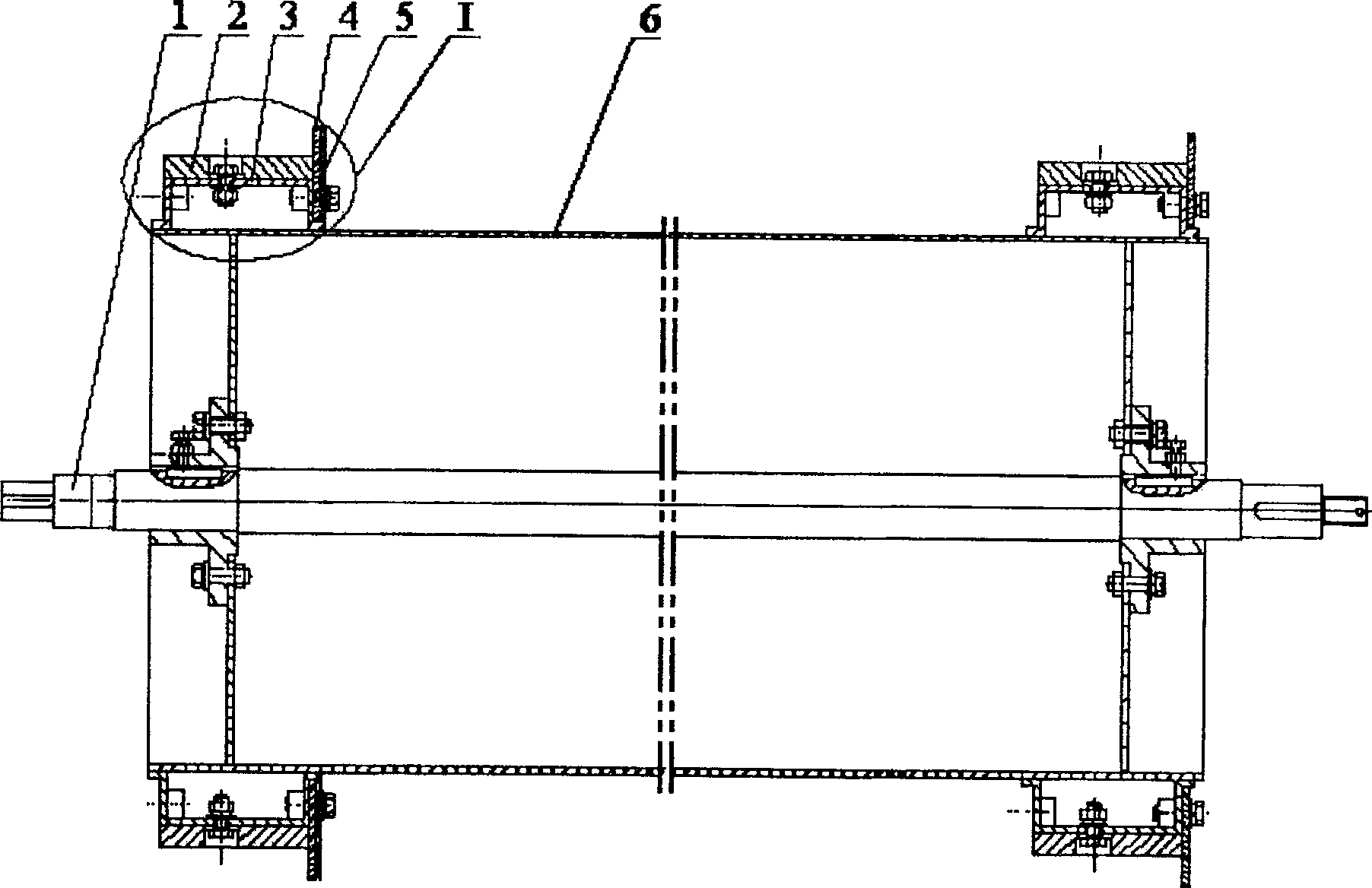

[0019] figure 1 It is the left view of the assembly of the axial flow threshing separation device, including the threshing cylinder and the concave plate. The threshing cylinder adopts a short-grain rod-plate tooth composite structure. Plate teeth 4 form a compound threshing element, and the short-grain rod-plate tooth compound threshing element is arranged in a spiral on the threshing drum such as Figure 10 shown. The threshing and separation of crops is achieved by the combined action of the rubbing of the short grain rod 2 and the striking of the plate teeth 4. During the threshing process, there are both rubbing and impact, high cleaning rate, small entrainment loss, less grain damage, and low handle rate. , the stalk is lightly broken, and the impurity content in the prolapse is low; the length of the short-grained rod 2 is 50-150mm, and the height of the plate teeth 4 is 60-100mm; the separation concave plate adopts a grid-punching combination form, and the front secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com