Latch needle

A technology of latch needles and latches, applied in the field of latch needles, which can solve the problems of hindering the function of latch needles, dust and fluff cannot be removed, and latch spring blockage, etc., to achieve the effect of smooth passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

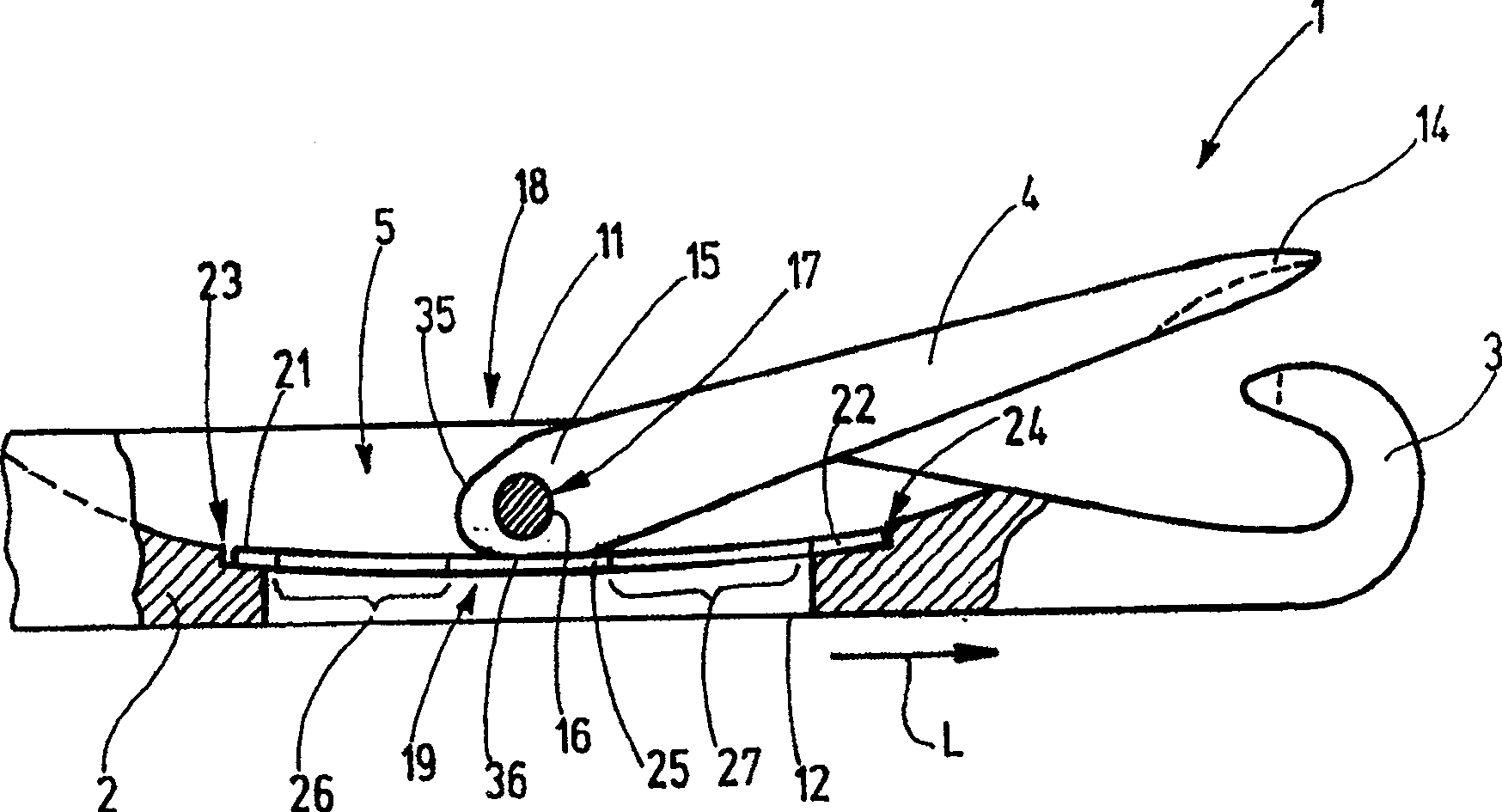

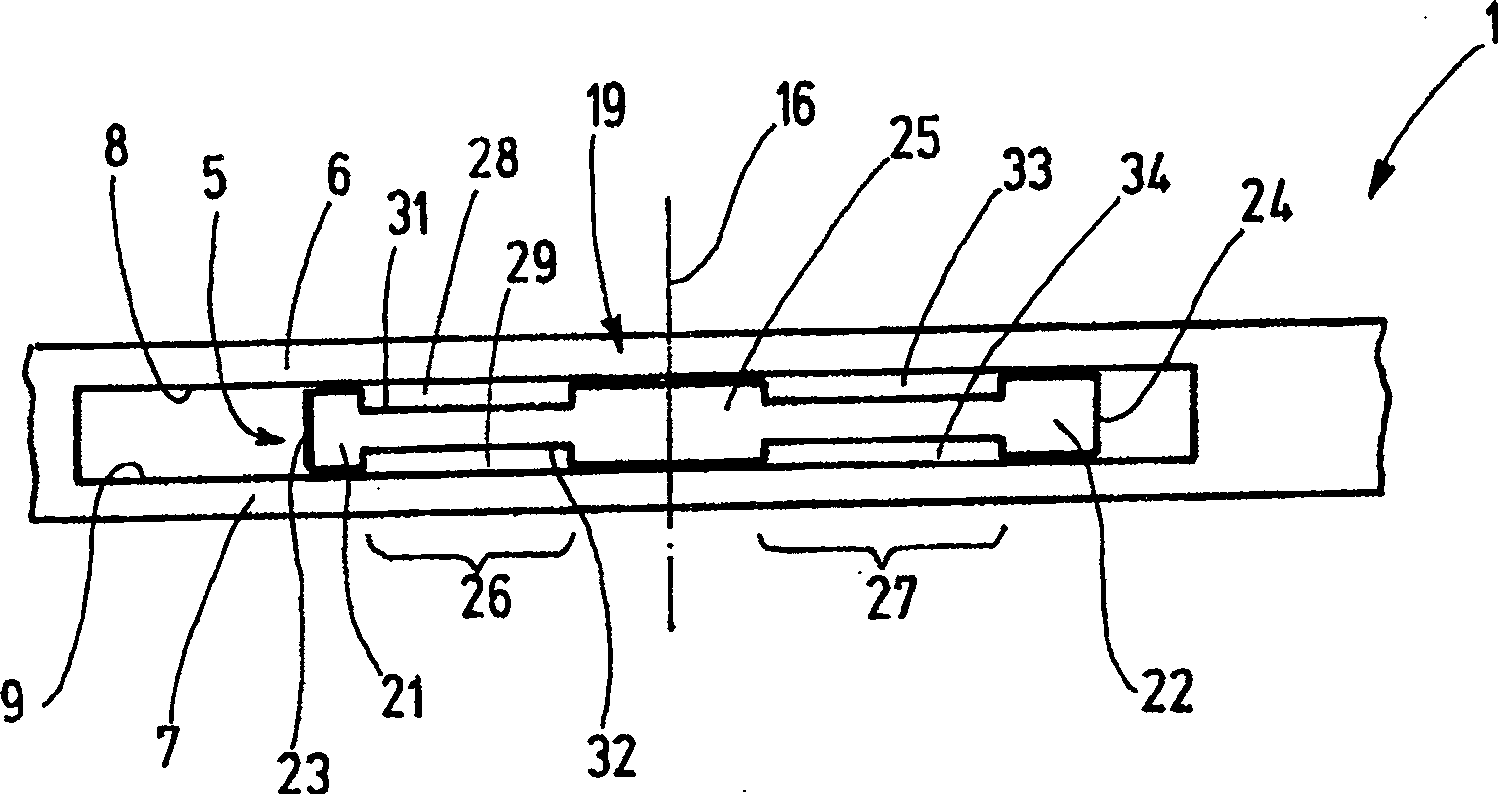

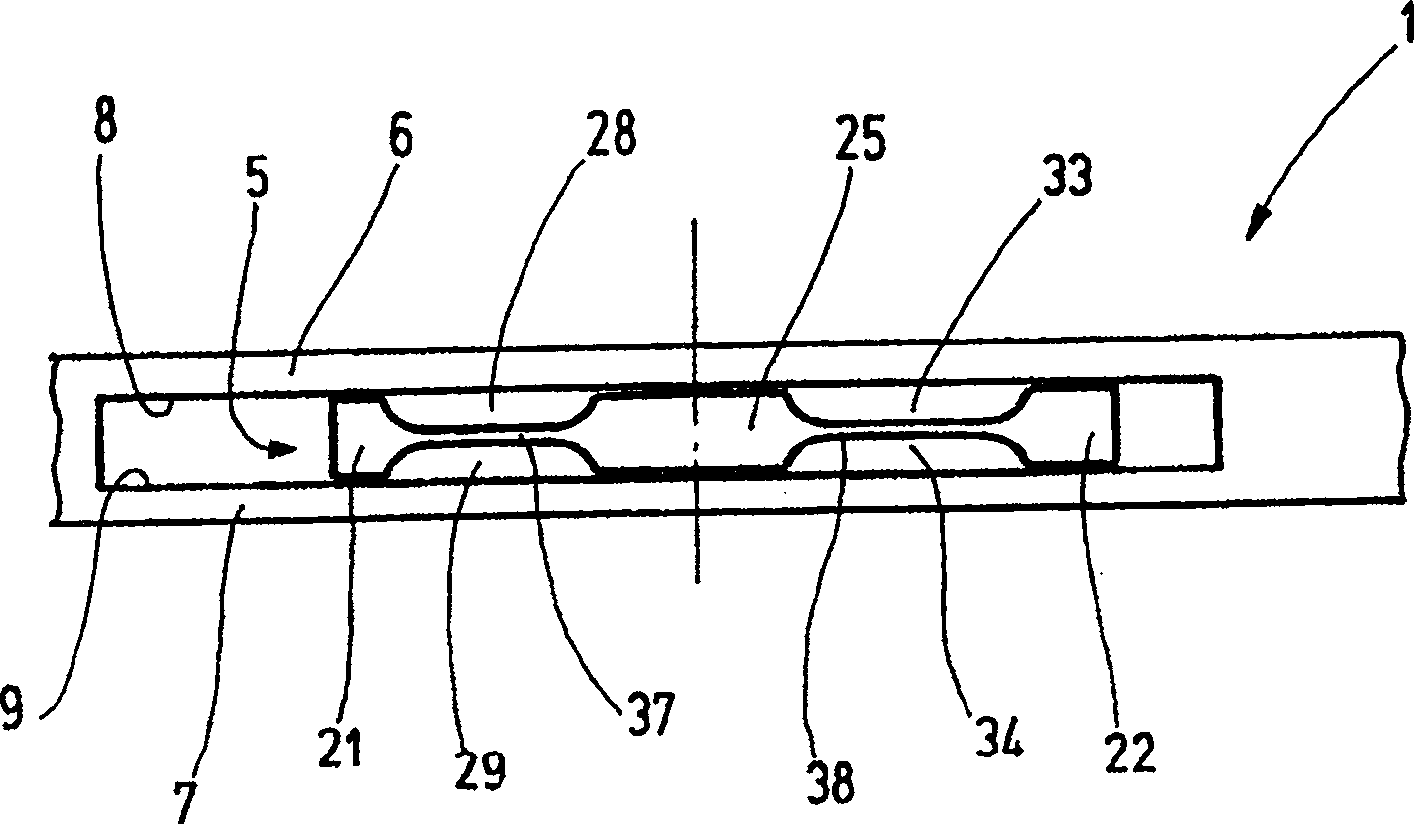

[0027] figure 1 A latch needle 1 is shown having a handle 2 , a hook 3 and a latch 4 arranged thereon. as from figure 2 As seen in the figure, the shank 2 has a latch seam 5, and the seam walls 6, 7 of the latch seam 5 have horizontal inner surfaces 8, 9 facing each other. The latch seam 5 forms a passage which ends at the latch needle side plate 11 and at the latch needle back 12 .

[0028] The latch 4 and its latch spoon 14 can rest on the tip of the hook 3 in the first position, and in the second position can be turned away from the hook 3 to the maximum, extending into the latch seam together with its latch shank end 15 5 in. The support pin 16 extends transversely with respect to the shank 2 through the latter and passes through the latch shank end 15 at a latch hole 17 . The needle latch shank end 15 forms a needle latch support device 18 together with the handle hole 17 and the support pin 16, and the needle latch support device 18 is used as a rotating support for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com