High-temperature, high pressure fluid ingredient analytical sensor

A high temperature and high pressure, sensor technology, applied in the field of sensors, can solve the problem of not being able to detect the composition of downhole fluid at any time, and achieve the effects of simple structure, good sealing performance and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

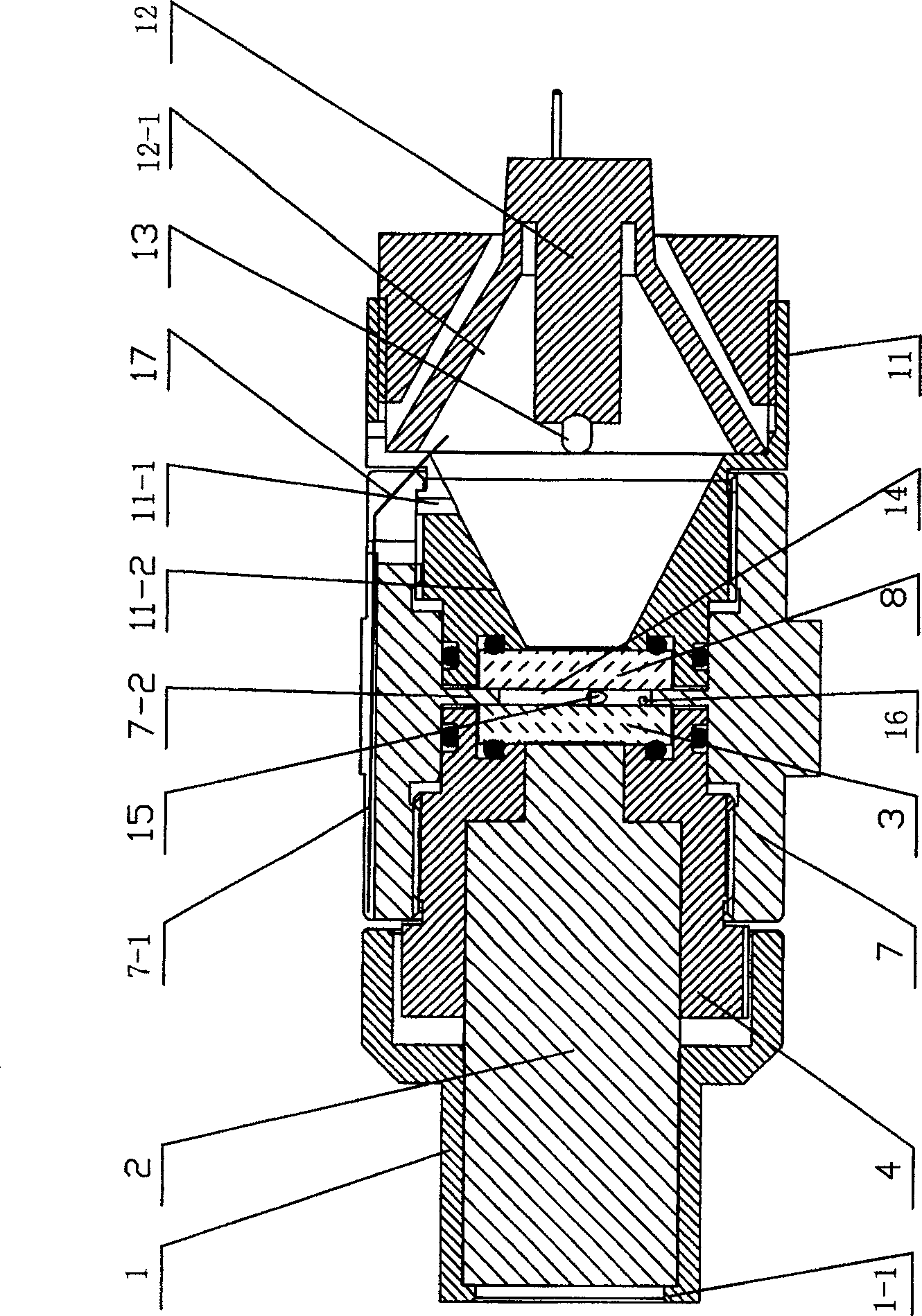

[0008] Below in conjunction with accompanying drawing and with best embodiment the present invention is described in detail:

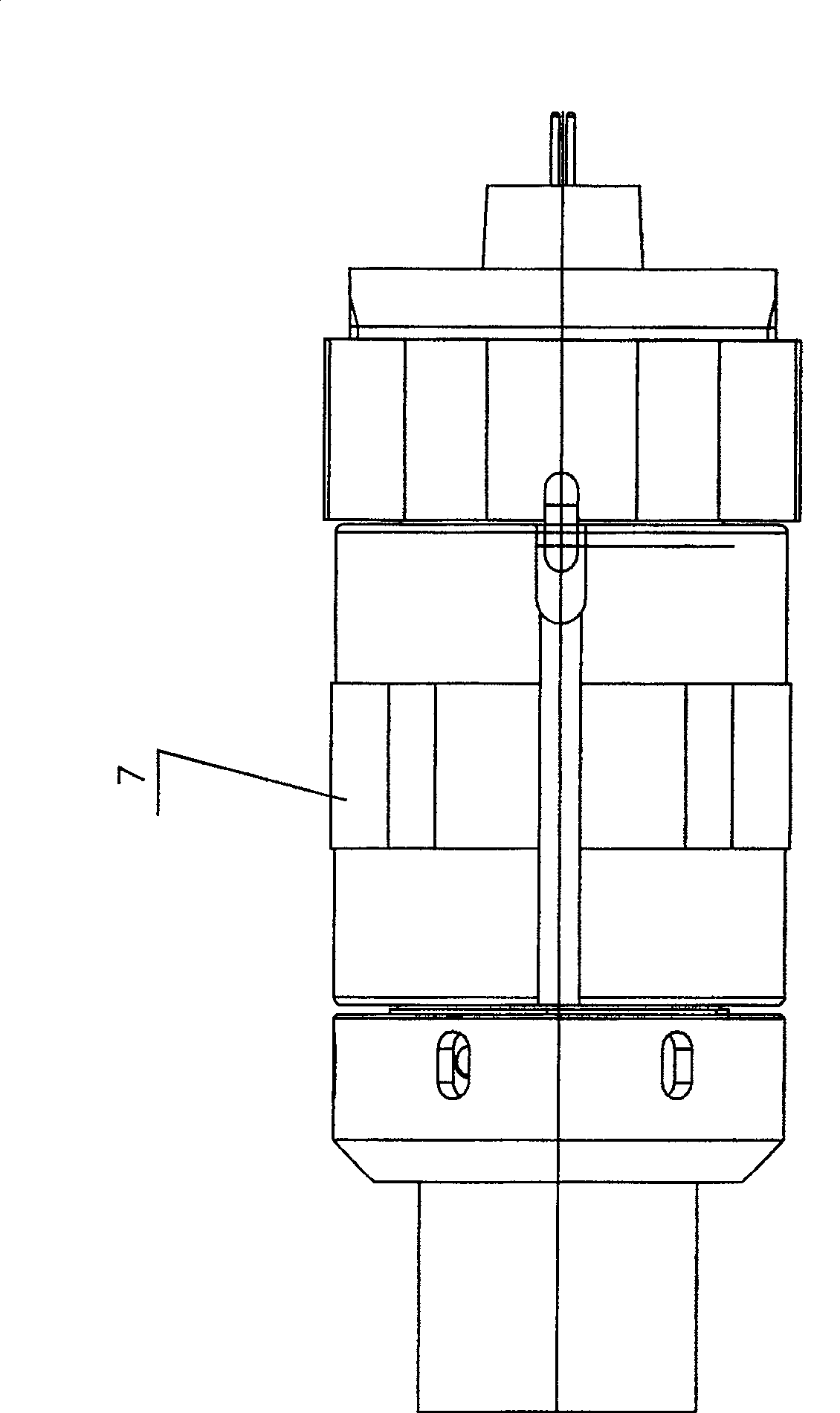

[0009] refer to figure 1 with figure 2 , a high-temperature and high-pressure fluid component analysis sensor, which includes a main sealing body 7, a pair of light-transmitting left glass sheet 3 and a right glass sheet 8 installed in the main sealing body 7 and arranged parallel to each other, located on the outside of the right glass sheet 8 And light can be irradiated to the emission light source 13 on the right glass sheet 8, the receiving optical fiber 2 that is arranged on the outside of the left glass sheet 3 for receiving the light passing through; there is a closed space 14 for containing fluid between a pair of glass sheets , on the main sealing body 7 there is a fluid inlet 15 and a fluid outlet 16 communicating with the closed space 14 . The fluid outlet 16 is smaller than the fluid inlet 15 . In this way, a certain amount of fluid can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com