Method for manufacturing barber scissors

A technology of barber scissors and scissors, which is applied in the field of manufacturing barber scissors, can solve problems such as inappropriateness and can only be used once, and achieve the effect of flexible activities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

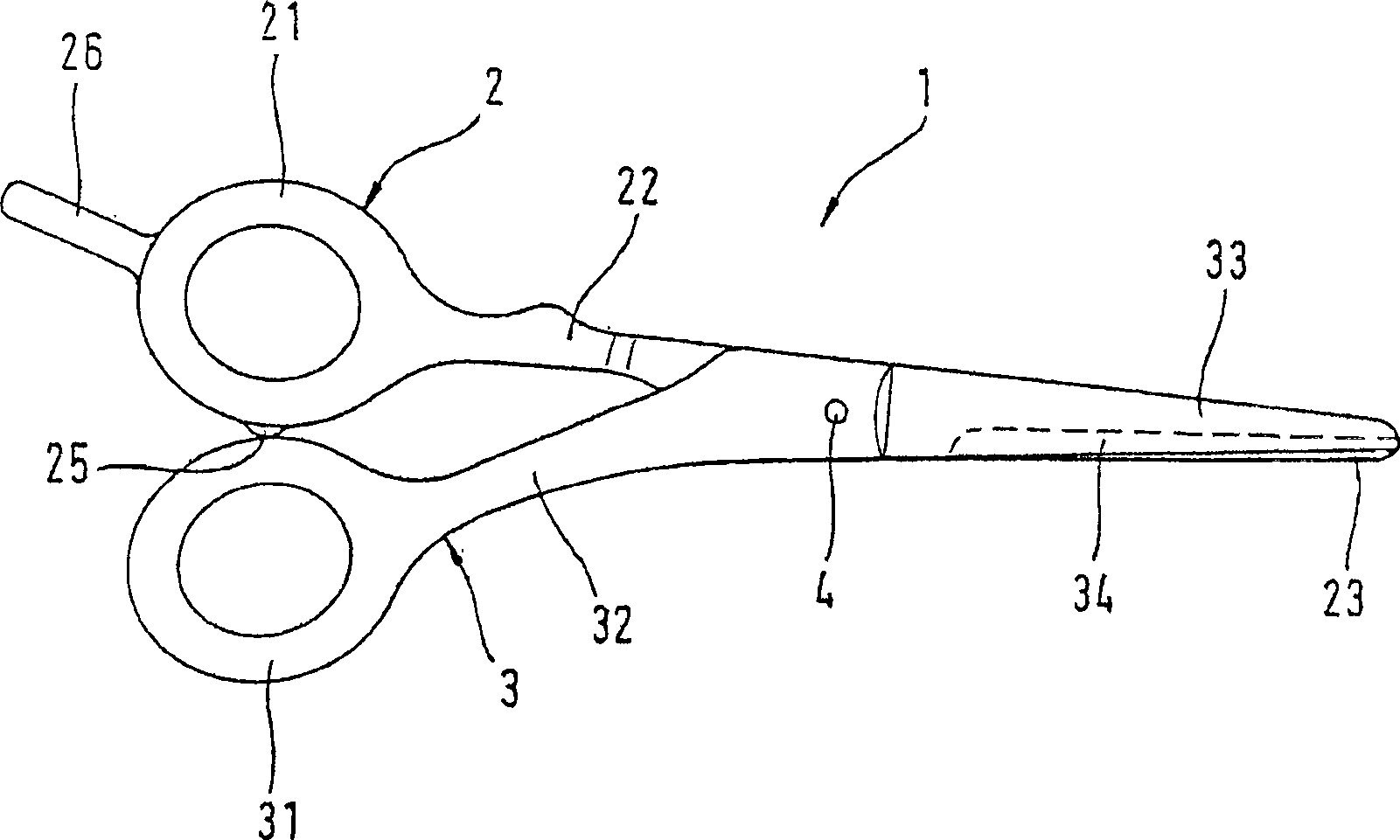

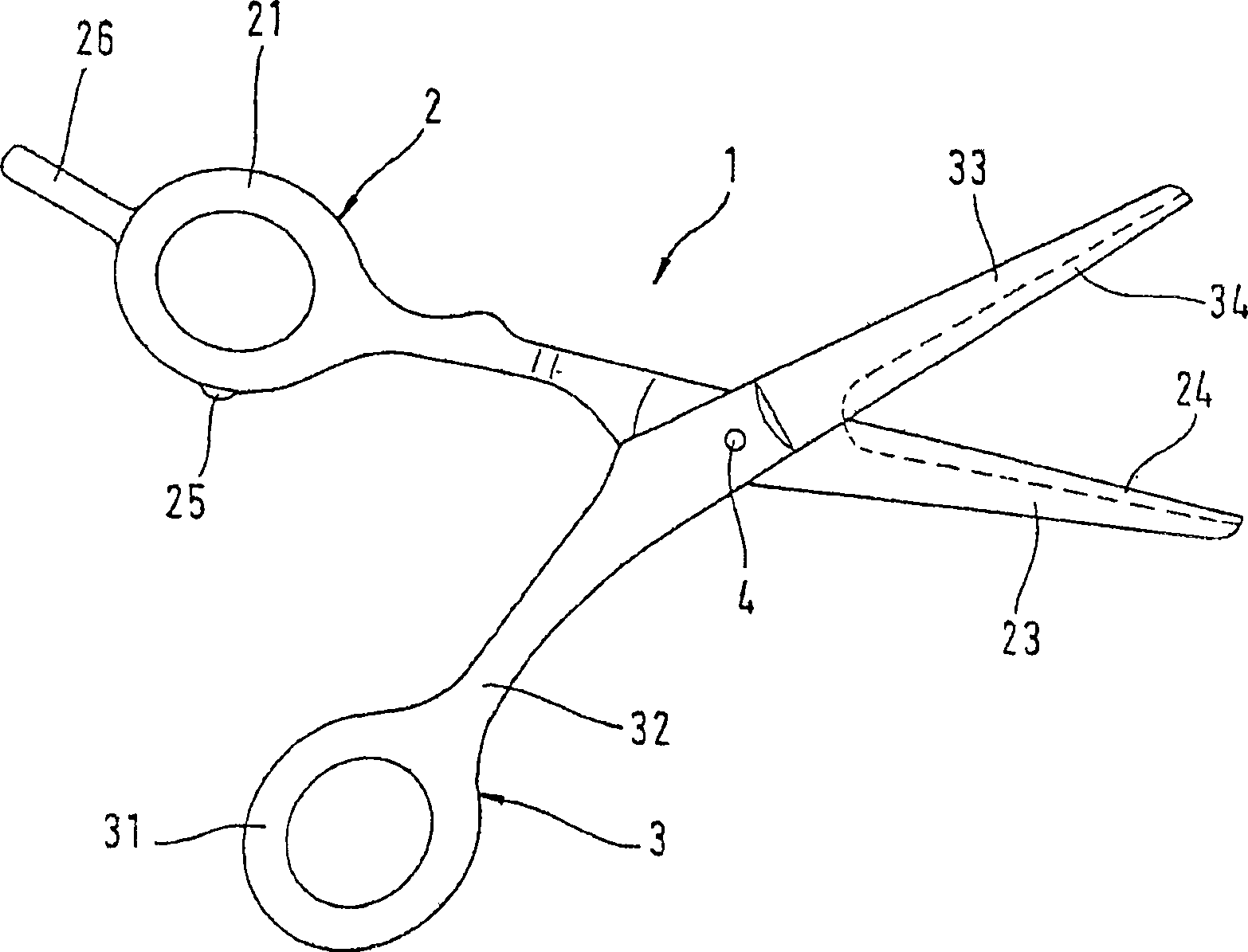

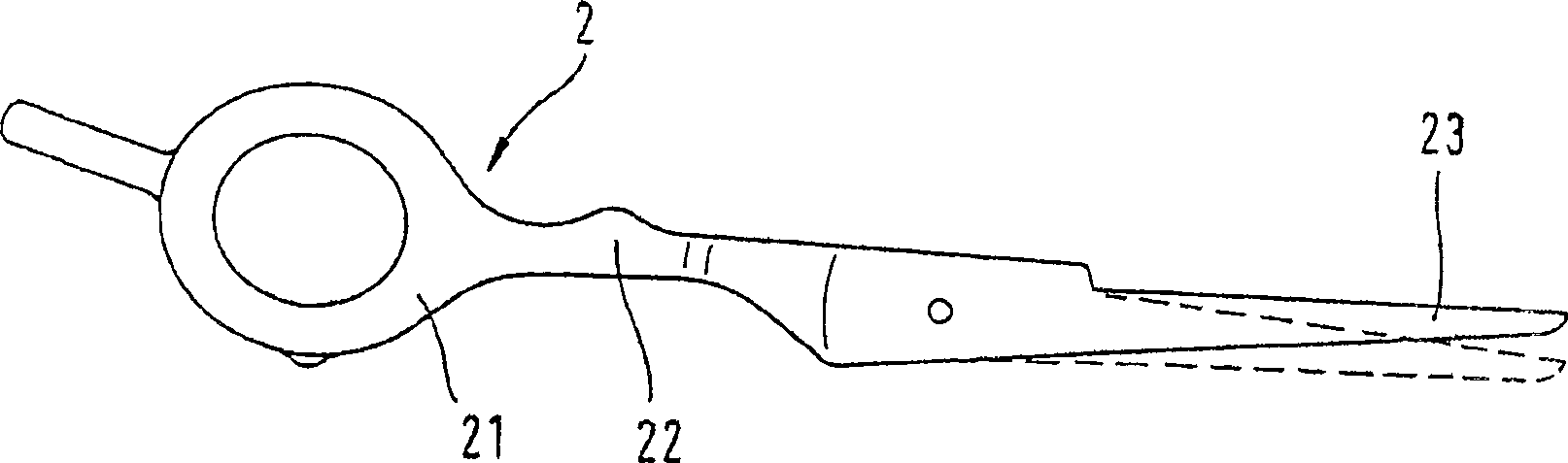

[0034] Such as figure 1 with figure 2 As shown in , the hair clipper 1 comprises two scissor halves 2 and 3 which are pivotally connected to each other by means of a locking pin 4 . The scissors half 2 includes a ring 21 , a handle 22 , a scissors edge 23 and a blade 24 . In addition, a knife edge stop 25 and a finger strut 26 can also be arranged on the ring 21 . The scissors half 3 includes a ring 31 , a handle 32 , a scissors edge 33 and a blade 34 .

[0035] The following will refer to Figures 3A-3C The manufacturing steps of the hair clipper 1 are explained by taking the scissor half 2 as an example, and the manufacturing steps of the scissor half 3 are similar.

[0036] First, the two scissors halves 2, 3 are provided and handled in their known conventional manner. Specifically, at the beginning of the work, while cutting the threads and drilling the threaded holes for the locking pins 4 in the form of bolts on the assembled part, the grinding and polishing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com